I-Titanium Alloy Welding

Sisigaba esinye sengxubevange eyenziwe ngesisombululo esiqinileyo sesigaba se-β. Ngaphandle konyango lobushushu, lunamandla aphezulu. Emva kokucima kunye nokuguga, i-alloy iqhubekile.Isinyathelo esinye sokuqinisa, amandla okushisa kwegumbi anokufikelela kwi-1372 ~ 1666 MPa; Kodwa ukuzinza kwe-thermal kubi, akufanele kusetyenziswe kwiqondo lokushisa eliphezulu.

I-alloy ye-biphasic, ineempawu ezintle ezibanzi, ukuzinza kwesakhiwo esihle, ukuqina okulungileyo, iplastiki kunye neempawu ze-deformation ephezulu yokushisa, kunokuba ngcono ukuqhutyelwa koxinzelelo olushushu, kunokucima, ukuguga ukuqinisa i-alloy. Amandla emva kokunyangwa kobushushu malunga ne-50% ~ 100% ephezulu kunoko emva kokuba i-annealing; Amandla obushushu obuphezulu, anokusebenza kwi-400℃ ~ 500℃ ubushushu ixesha elide, ukuzinza kwayo kwe-thermal kungaphantsi kwe-α titanium alloy.

Phakathi kwee-alloys ezintathu ze-titanium, eyona nto isetyenziswa ngokuqhelekileyo yi-α titanium alloy kunye ne-α + β titanium alloy; Ukusebenza kokusika kwe-alpha titanium alloy iyona nto ibhetele, ilandelwa ngu-α + β titanium alloy, kunye ne-β titanium alloy iyona nto imbi. Ikhowudi yealloyi ye-titanium ye-TA, ikhowudi ye-β ye-titanium ye-TB, i-α+β ikhowudi ye-titanium ye-TC.

Ingxubevange ye-Titanium inokohlulwa ibe yingxubevange yokumelana nobushushu, ialloyi yamandla aphezulu, i-corrosion resistant alloy (titanium - molybdenum, titanium - palladium alloy, njl.), ialloy yobushushu obuphantsi kunye nomsebenzi okhethekileyo wealloy (titanium - intsimbi yokugcina i-hydrogen kunye ne-titanium - inkumbulo ye-nickel ingxubevange). Ukubunjwa kunye neepropati ze-alloys eziqhelekileyo ziboniswe kwitheyibhile.

Ukuqulunqwa kwezigaba ezahlukeneyo kunye ne-microstructure ye-alloys ye-titanium ephathwa ngobushushu inokufumaneka ngokulungelelanisa inkqubo yonyango lokushisa. Ngokuqhelekileyo kukholelwa ukuba izakhiwo ezintle ezilinganayo zineplastiki engcono, ukuzinza kwe-thermal kunye namandla okukhathala. Ulwakhiwo lwe-spiculate lunokuqina okuphezulu, amandla okurhubuluza kunye nokuqina kokwaphuka. I-equiaxial kunye neenaliti ezixubileyo ezixubileyo zineempawu ezibanzi ezingcono. I-Titanium luhlobo olutsha lwetsimbi, ukusebenza kwe-titanium kuhambelana nomxholo wekhabhoni, i-nitrogen, i-hydrogen, i-oksijini kunye nezinye izinto ezingcolileyo, eyona nto icocekileyo ye-titanium iodide yokungcola ayikho ngaphezu kwe-0.1%, kodwa amandla ayo aphantsi, iplastiki ephezulu .

Iipropati ze-99.5% ye-titanium esulungekileyo yoshishino zezi zilandelayo: ubuninzi ρ=4.5g/ cubic cm, indawo yokunyibilika 1725℃, i-thermal conductivity λ=15.24W/(mK), amandla okuqina σb=539MPa, elongation δ=25%, icandelo ukushwabana ψ=25%, imodyuli elastiki E=1.078×105MPa, ubulukhuni HB195. Ubuninzi be-titanium alloy ngokubanzi malunga ne-4.51g / cubic centimeter, kuphela i-60% yentsimbi, amandla e-titanium ecocekileyo isondele kumandla entsimbi eqhelekileyo, amandla athile aphezulu e-titanium alloy idlula amandla amaninzi ensimbi ye-alloy structural. Ngoko ke, amandla athile (amandla / ubuninzi) be-titanium alloy bukhulu kakhulu kunezinye izinto zezakhiwo zetsimbi, njengoko kuboniswe kwiThebhile 7-1. Inokuvelisa iinxalenye kunye namacandelo anamandla amakhulu eyunithi, ukuqina okulungileyo kunye nobunzima obulula. Okwangoku, ii-alloys ze-titanium zisetyenziswa kumacandelo enjini, amathambo, ulusu, iziqhoboshi kunye nezixhobo zokumisa.

Thumela umyalezo wakho kuthi:

-

Aluminiyam CNC Machining Parts

-

I-Aluminiyam yePhepha leMetal Fabrication

-

Axis High Precision CNC Machining Parts

-

Izahlulo zoomatshini be-CNC base-Itali

-

CNC Machining Aluminiyam iinxalenye

-

Auto Parts Machining

-

I-Titanium Alloy Forgings

-

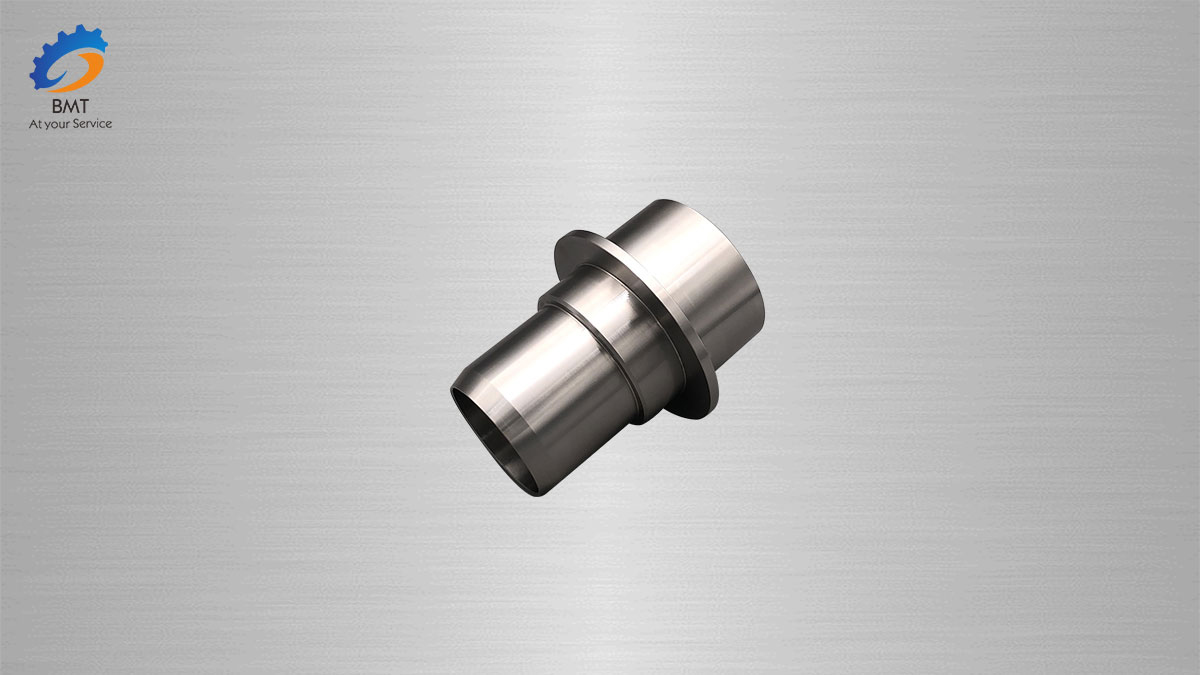

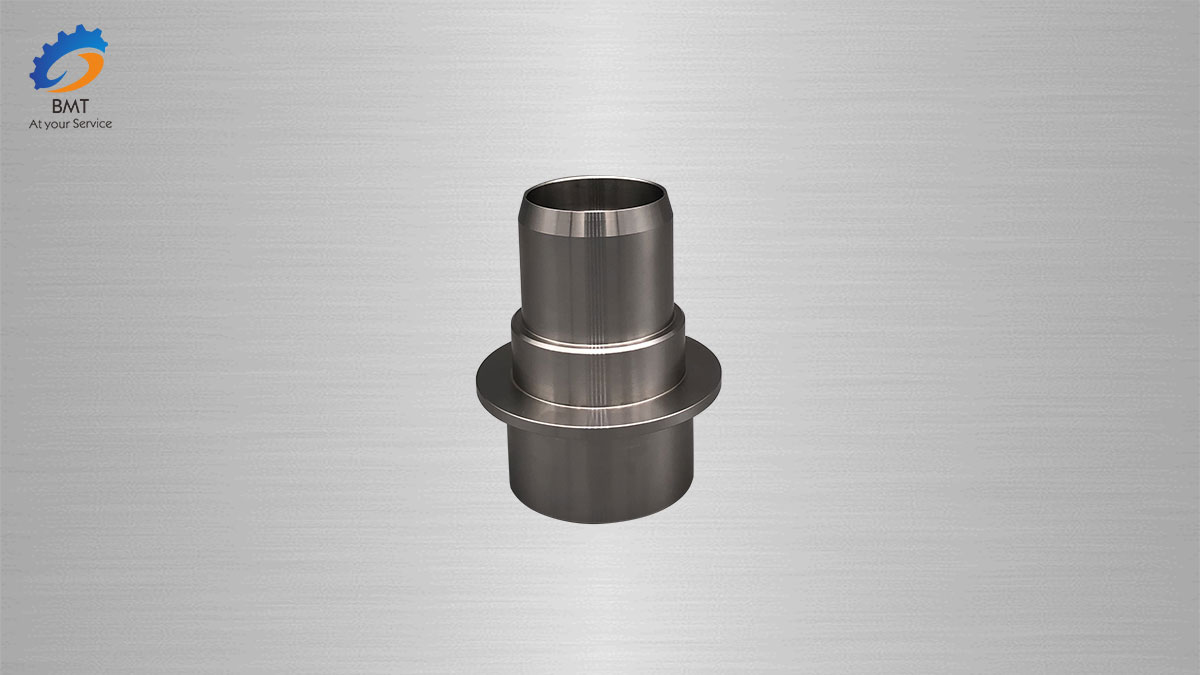

I-Titanium kunye ne-Titanium Alloy Fittings

-

I-Titanium kunye ne-Titanium Alloy Forgings

-

Iingcingo zeTitanium kunye neTitanium Alloy

-

Iibha zeTitanium

-

Imibhobho yeTitanium engenamthungo/iiThubhu

-

I-Titanium Welded imibhobho / iiThubhu