CNC Machining Operational Safety

Ukuveliswa kwempucuko

Izixhobo zoomatshini be-CNC zizixhobo eziphambili zokucwangcisa kunye neqondo eliphezulu lokuzenzekelayo kunye nesakhiwo esinzima. Ukuze unike umdlalo opheleleyo ekuphakameni kwezixhobo zoomatshini, ukuphucula ukusebenza kakuhle kwemveliso, ukulawula, ukusebenzisa, kunye nokulungisa izixhobo zomatshini we-CNC, umgangatho wabachwephesha kunye nokuveliswa kwempucuko kubaluleke kakhulu. . Ukongeza kokuqhelana nokusebenza kwezixhobo zoomatshini be-CNC, abaqhubi kufuneka baphuhlise imikhwa elungileyo yokusebenza kunye nezimbo zokusebenza ezingqongqo kwimveliso ephucukileyo, kwaye babe neempawu ezintle zobuchwephesha, imvakalelo yoxanduva kunye nomoya wentsebenziswano. Ezi ngongoma zilandelayo kufuneka zenziwe ngexesha lokusebenza:

(1) Ukuthobela ngokungqongqo imimiselo yokusebenza ekhuselekileyo yezixhobo zoomatshini be-CNC. Musa ukusebenzisa umatshini ngaphandle koqeqesho lobungcali.

(2) Ukuthobela ngokuthe ngqo inkqubo yokuhamba kunye nokutshintsha.

(3) Sebenzisa kwaye ulawule umatshini kakuhle, kwaye ube nengqiqo eqinileyo yoxanduva lomsebenzi.

(4) Gcina indawo engqonge isixhobo somatshini we-CNC icocekile kwaye icocekile.

(5) Abanini-zithuthi bafanele banxibe iimpahla zokusebenza nezihlangu zokusebenza, yaye akukho mpahla iyingozi ifanele inxitywe okanye inxitywe.

IiNkqubo zokuSebenza ngoKhuseleko

Ukuze usebenzise isixhobo somatshini we-CNC ngokuchanekileyo nangengqiqo, ukunciphisa iziganeko zokungaphumeleli kwayo, indlela yokusebenza. Isixhobo somatshini sinokusebenza kuphela ngemvume yomphathi wesixhobo somatshini.

(1) Izilumkiso ngaphambi kokuba uqalise

1) Umqhubi kufuneka aqhelane nokusebenza kunye neendlela zokusebenza zesixhobo somatshini we-CNC. Isixhobo somatshini sinokusebenza kuphela ngemvume yomphathi wesixhobo somatshini.

2) Ngaphambi kokunika amandla kwisixhobo somatshini, jonga ukuba i-voltage, uxinzelelo lomoya, kunye noxinzelelo lweoyile ziyahlangabezana neemfuno zokusebenza.

3) Khangela ukuba indawo eshukumayo yesixhobo somatshini ikwimeko yokusebenza eqhelekileyo.

4) Khangela ukuba kukho ukulalela okanye ukumisela umda kwibhentshi yokusebenza.

5) Khangela ukuba ngaba izinto zombane ziqinile kwaye ukuba i-wiring icinyiwe.

I-6) Khangela ukuba ngaba ucingo oluphantsi lwesixhobo somatshini luxhomekeke ngokuthembekileyo kwintambo yomhlaba we-workshop (ibaluleke kakhulu kwisiqalo sokuqala).

7) Vula umbane oyintloko kuphela emva kokuba amalungiselelo ngaphambi kokuqala umatshini agqitywe.

(2) Izilumkiso ngexesha leNkqubo yeBoot

1) Sebenza ngokungqongqo ngokuhambelana nokulandelelana kokuqalisa kwincwadana yesixhobo somatshini.

2) Kwiimeko eziqhelekileyo, kufuneka uqale ubuyele kwindawo yokubhekisela kumatshini ngexesha lenkqubo yokuqalisa ukuseka isixhobo somatshini njengenkqubo eqhelekileyo.

3) Emva kokuqala umatshini, vumela umatshini ukuba wome ngaphezu kwemizuzu eyi-15 ukwenza umatshini ufikelele kwisimo esilungeleleneyo.

I-4) Emva kokuvala, kufuneka ulinde ngaphezu kwemizuzu emi-5 ngaphambi kokuba uqalise kwakhona, kwaye akukho kuqaliswa rhoqo okanye ukusebenza kokuvala kuvunyelwe ngaphandle kweemeko ezizodwa.

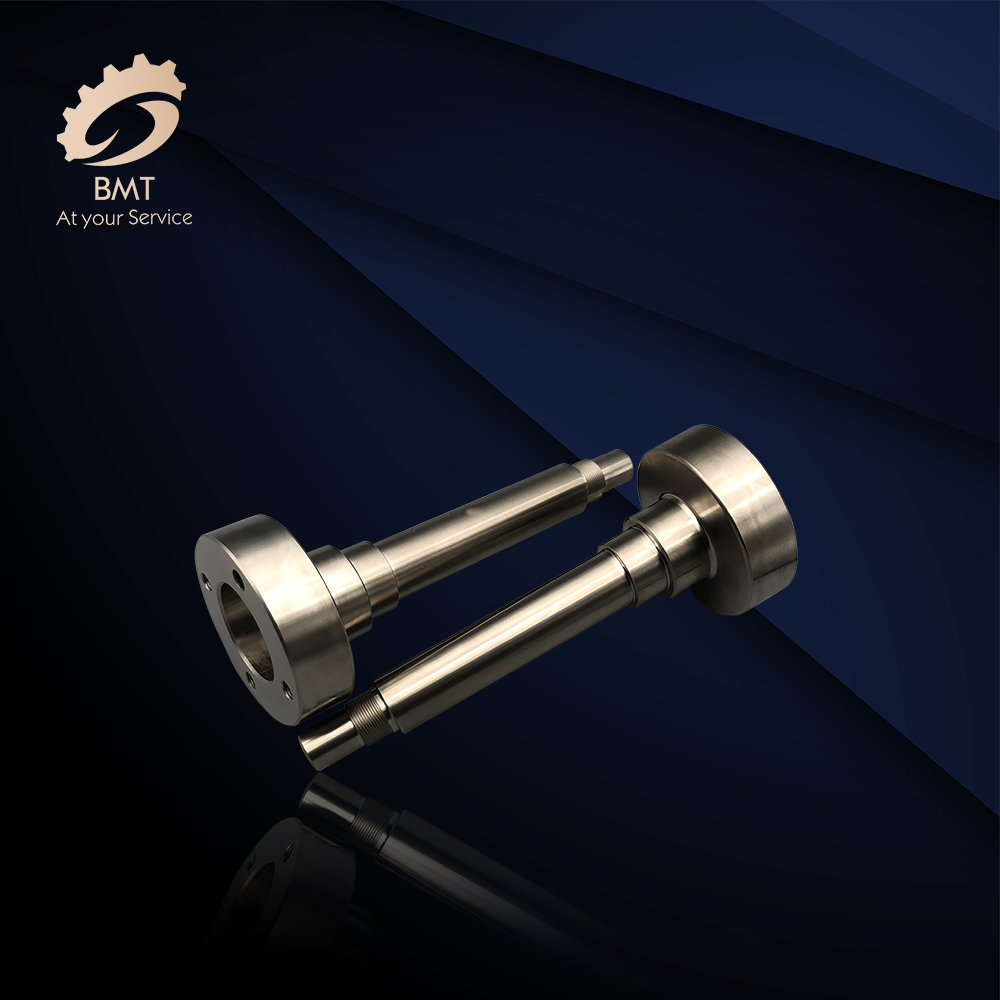

Incam yolu hlobo lwesixhobo sokuguqula iqulethwe ngamacandelo aphambili kunye nesibini, njengezixhobo ze-900 zokuguqula zangaphakathi nangaphandle, izixhobo zokuguqula ubuso ngasekhohlo nasekunene, izixhobo zokuguqula i-grooving (ukusika), kunye nemida eyahlukeneyo yokusika yangaphandle nangaphakathi. ama-chamfers amancinci amancinci. Isixhobo sokuguqula umngxuma. Indlela yokukhethwa kweeparameters zejometri yesixhobo sokujika esichongiweyo (ingakumbi i-angle yejometri) ngokusisiseko iyafana neyokujika okuqhelekileyo, kodwa iimpawu ze-CNC machining (ezifana nomzila womatshini, ukuphazamiseka komatshini, njl. njl.) kufuneka ziqwalaselwe ngokubanzi. , kunye nencam yesixhobo ngokwayo kufuneka ithathwe njengamandla.