Umatshini we-CNC umisela iMali yokusika

Kwiprogram ye-NC, umdwelisi weprogram kufuneka anqume inani lokusika inkqubo nganye kwaye ayibhale kwiprogram ngendlela yemiyalelo.Iiparamitha zokusika ziquka isantya se-spindle, isixa sokusika umva kunye nesantya sokutya.Kwiindlela ezahlukeneyo zokucutshungulwa, iiparamitha ezahlukeneyo zokusika kufuneka zikhethwe.Umgaqo wokukhethwa kwexabiso lokusika kukuqinisekisa ukuchaneka komatshini kunye noburhabaxa bomhlaba wamacandelo, ukunika umdlalo opheleleyo ekusebenzeni kokusika kwesixhobo, ukuqinisekisa ukuqina kwesixhobo esinengqiqo, kunye nokunika umdlalo opheleleyo ekusebenzeni kwesixhobo somatshini ukwandisa imveliso. kunye nokunciphisa iindleko.

1. Misela isantya seSpindle

Isantya se-spindle kufuneka sikhethwe ngokwesantya esivumelekileyo sokusika kunye nobubanzi bomsebenzi (okanye isixhobo).Ifomula yokubala yile: n=1000 v/7 1D phi: v?isantya sokusika, iyunithi yi-m / m intshukumo, enqunywe ngokuhlala kwesixhobo;n sisantya sokusonta, iyunithi yi-r/min, kunye no-D yidayamitha yesixhobo sokusebenza Okanye idiamitha yesixhobo, nge-mm.Kubalwa isantya sokusonta n, isantya isixhobo somatshini esinaso okanye sikufutshane kufuneka sikhethwe ekugqibeleni.

2. Misela umlinganiselo wokutyisa

Isantya sokutya yiparameter ebalulekileyo kwiiparitha zokusika izixhobo zomatshini we-CNC, ezikhethwa ngokukodwa ngokuchaneka kwe-machining kunye neemfuno zobunzima bomhlaba wamacandelo kunye neempawu eziphathekayo zezixhobo kunye nezixhobo zokusebenza.Ubuninzi bezinga lokutya lilinganiselwe ngokungqongqo kwesixhobo somatshini kunye nokusebenza kwenkqubo yokutya.Umgaqo wokumisela izinga lokutya: Xa iimfuno zomgangatho we-workpiece zinokuqinisekiswa, ukuze kuphuculwe ukusebenza kakuhle kwemveliso, izinga eliphezulu lokutya linokukhethwa.Ngokuqhelekileyo ekhethiweyo kuluhlu lwe-100-200mm / min;xa usika, ukucubungula imingxuma enzulu okanye ukucubungula ngezixhobo zetsimbi eziphezulu, kuyacetyiswa ukuba ukhethe isantya esisezantsi sokutya, esikhethwe ngokubanzi kwi-20-50mm / min;xa ukuchaneka kokucubungula, umphezulu Xa imfuno yobunzima iphezulu, isantya sokutya kufuneka sikhethwe sincinci, ngokubanzi kuluhlu lwe-20-50mm / min;xa isixhobo singenanto, ngakumbi xa umgama omde "ubuyela kwi-zero", unokuseta izicwangciso zenkqubo ye-CNC yesixhobo somatshini Ireyithi ephezulu yokutya.

3. Qinisekisa isixa seZixhobo ezingasemva

Ubungakanani bokubuyisela umva bunqunywe ngokungqongqo kwesixhobo somatshini, i-workpiece kunye nesixhobo sokusika.Xa ukuqina kuvumela, isixa se-back-grabbing kufuneka silingane nesibonelelo somatshini we-workpiece kangangoko kunokwenzeka, oko kunokunciphisa inani lokupasa kunye nokuphucula ukusebenza kwemveliso.Ukuze kuqinisekiswe umgangatho womgangatho owenziwe ngoomatshini, isibonelelo esincinci sokugqiba singashiywa, ngokubanzi 0.2-0.5mm.Ngamafutshane, ixabiso elithile lexabiso lokusika kufuneka ligqitywe ngokulinganisa ngokusekelwe ekusebenzeni kwesixhobo somatshini, iincwadi ezihambelanayo kunye namava okwenene.

Kwangaxeshanye, isantya se-spindle, ukusika ubunzulu kunye nesantya sokutya sinokuhlengahlengiswa omnye komnye ukwenza elona nani lihle lokusika.

Isixa sokusika asiyona nje ipharamitha ebalulekileyo ekufuneka igqitywe ngaphambi kokuba isixhobo somatshini sihlengahlengiswe, kodwa nokuba ixabiso layo linengqiqo okanye lingenalo impembelelo ebaluleke kakhulu kumgangatho wokucubungula, ukusebenza kakuhle, kunye neendleko zokuvelisa.Into ebizwa ngokuba "yingqiqo" yokusika imali ibhekisela kwisixa sokusika esenza ukusetyenziswa ngokupheleleyo kokusika kwesixhobo kunye nokusebenza okuguquguqukayo (amandla, i-torque) yesixhobo somatshini ukufumana imveliso ephezulu kunye neendleko eziphantsi zokucutshungulwa phantsi kwesiseko. ukuqinisekisa umgangatho.

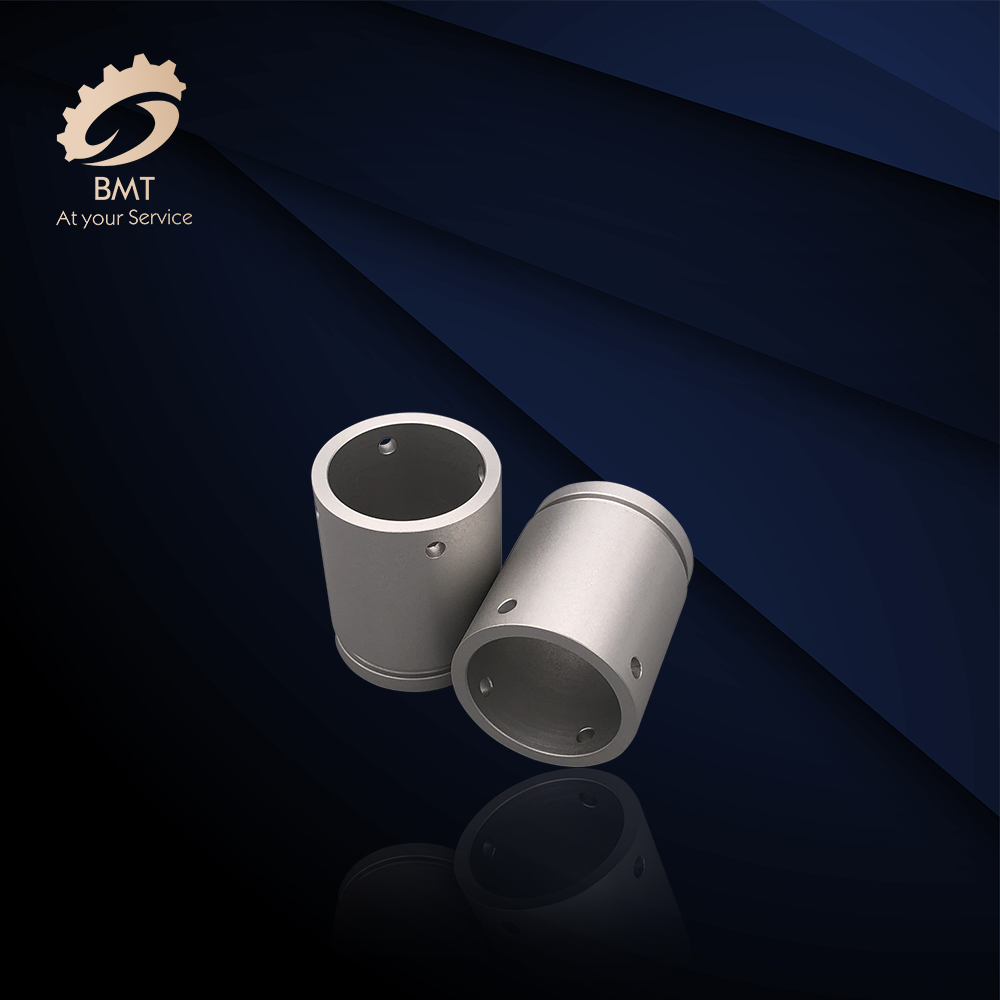

Incam yolu hlobo lwesixhobo sokuguqula iqulethwe ngamacandelo aphambili kunye nesibini, njengezixhobo ze-900 zokuguqula zangaphakathi nangaphandle, izixhobo zokuguqula ubuso ngasekhohlo nasekunene, izixhobo zokuguqula i-grooving (ukusika), kunye nemida eyahlukeneyo yokusika yangaphandle nangaphakathi. ama-chamfers amancinci amancinci.Isixhobo sokuguqula umngxuma.Indlela yokukhethwa kweeparameters zejometri yesixhobo sokujika esichongiweyo (ingakumbi i-angle yejometri) ngokusisiseko iyafana neyokujika okuqhelekileyo, kodwa iimpawu ze-CNC machining (ezifana nomzila womatshini, ukuphazamiseka komatshini, njl. njl.) kufuneka ziqwalaselwe ngokubanzi. , kunye nencam yesixhobo ngokwayo kufuneka ithathwe njengamandla.