CNC Machining Iimpazamo 2

Iimpazamo ezibangelwa ukuguqulwa kwe-thermal yenkqubo yenkqubo ye-thermal deformation yenkqubo yenkqubo inempembelelo enkulu kwiimpazamo ze-machining, ngokukodwa kwi-machining echanekileyo kunye ne-machining enkulu, iimpazamo ze-machining ezibangelwa yi-thermal deformation ngamanye amaxesha zingabalelwa kwi-50% yephutha elipheleleyo le-workpiece.

Lungisa impazamo kwinkqubo nganye yomatshini, rhoqo kwinkqubo yenkqubo ukwenza uhlobo olunye lomsebenzi wohlengahlengiso. Ngenxa yokuba uhlengahlengiso alunakuchaneka ngokupheleleyo, kwenzeka impazamo yohlengahlengiso. Kwinkqubo yenkqubo, ukuchaneka kwesithuba somsebenzi kunye nesixhobo kwisixhobo somatshini siqinisekiswa ngokulungelelanisa isixhobo somatshini, isixhobo, i-fixture okanye i-workpiece. Xa ukuchaneka kwasekuqaleni kwesixhobo somatshini, isixhobo sokusika, i-fixture kunye ne-workpiece engenanto yonke ihlangabezana neemfuno zobuchwepheshe ngaphandle kokuqwalasela izinto eziguquguqukayo, impazamo yokulungelelanisa idlala indima ebalulekileyo kwimpazamo yomatshini.

Amalungu empazamo yokulinganisa kwinkqubo okanye emva kwenkqubo yokulinganisa, ngenxa yendlela yokulinganisa, ukuchaneka kokulinganisa kunye nomsebenzi kunye nezinto ezizimeleyo kunye nenjongo zichaphazela ngokuthe ngqo ukuchaneka komlinganiselo. I-9, uxinzelelo lwangaphakathi ngaphandle kwamandla angaphandle kwaye lukhona kwiindawo zoxinzelelo lwangaphakathi, olubizwa ngokuba nguxinzelelo lwangaphakathi. Emva kokuba uxinzelelo lwangaphakathi lwenziwe kwi-workpiece, luya kwenza i-workpiece yesinyithi kwindawo engazinzanga yamandla aphezulu. Iza kuguqula ngokuzenzekelayo kwisimo esizinzileyo samandla aphantsi amandla, ehamba kunye ne-deformation, ukwenzela ukuba i-workpiece ilahlekelwe ukuchaneka kwayo kwasekuqaleni.

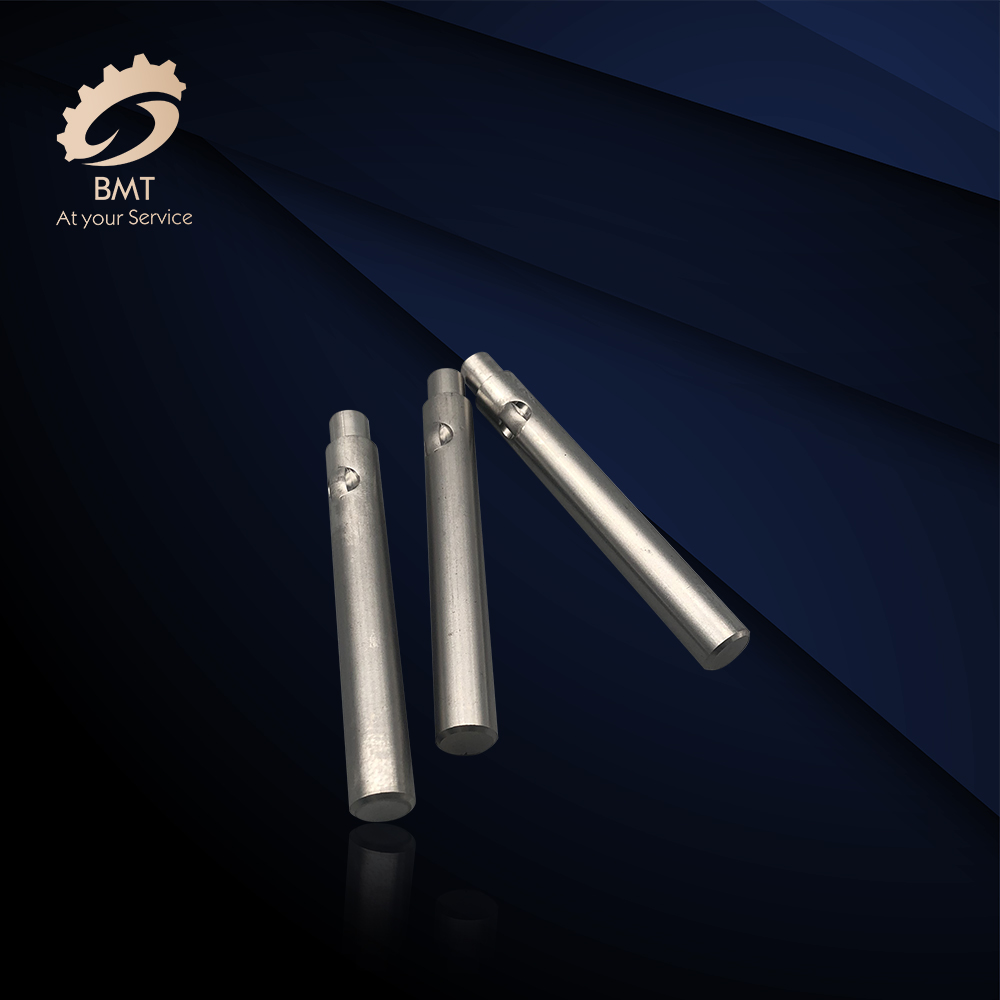

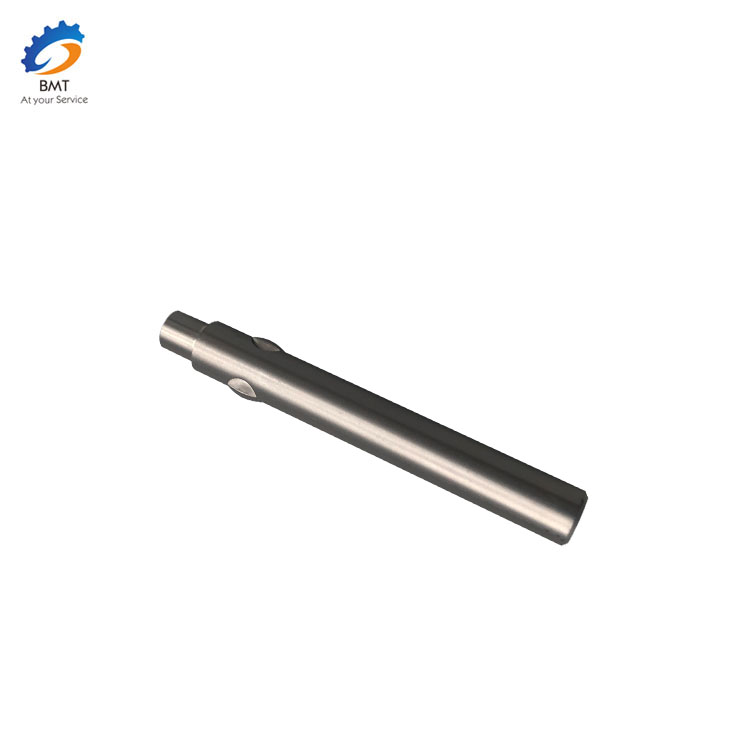

Izixhobo kwinkqubo yokulungiswa koomatshini kubaluleke kakhulu, ngokuthe ngqo kunye nomgangatho wokusetyenzwa kunye nokuchaneka kokulungiswa kuhambelana ngokusondeleyo, kuphuhliso olukhawulezayo lokwenziwa kwemveliso namhlanje, izinto ezahlukeneyo zezinto ezintsha, iteknoloji entsha ivela ngokungenasiphelo, isixhobo sezinto kunye itekhnoloji nayo ikwinguqu eqhubekayo kuhlaziyo. Ekubhekaneni nokunyusa iimfuno zokucubungula, njengomntu osebenza ngomatshini ukuqonda iintlobo zezixhobo kunye nemigangatho yokukhetha izixhobo, namhlanje i-BMT iza kuthetha nawe: zeziphi iintlobo zezixhobo kwi-machining? Indlela yokukhetha isixhobo?

Ziziphi iintlobo zezixhobo zokusika kwi-machining?

1. Ngokohlelo lwezixhobo zokusebenza

Isantya esiphezulu sentsimbi: amandla okugoba aphezulu kunye nokuqina kwempembelelo, ukusebenza kakuhle.

I-Hard alloy: Indlela yokubeka umphunga wekhemikhali eqatywe nge-titanium carbide, i-titanium nitride, i-alumina eqinileyo okanye umaleko oqinileyo odibeneyo, ukuze isixhobo sinxibe buphantsi, ubomi benkonzo ende.

2. Ngokwentshukumo yokusika yokuhlelwa kwesixhobo

Izixhobo jikelele: izixhobo ezisetyenziswa ngokuqhelekileyo, iplani, i-milling cutter, i-boring cutter, i-drill, i-reaming drill, i-reamer kunye nesarha.

Izixhobo zokubumba: isixhobo sokubumba esisetyenziswa ngokuqhelekileyo, ukwenza iplani, ukwenza i-milling cutter, i-broach, i-taper reamer kunye nazo zonke iintlobo zezixhobo zokulungisa intambo.

Izixhobo zophuhliso: isitovu esisetyenziswa ngokuqhelekileyo, imilo yegiya, ishaver yegiya, iplani yegiya ye-bevel kunye ne-bevel gear milling cutter disc, njl.

3. Ngokomsebenzi wesixhobo ulwahlulo

Integral: i-edge yokusika yenziwa kumzimba wemela.

Uhlobo lwe-Welding: ukubethelela i-blade kumzimba wentsimbi yemela

Ukubambelela ngoomatshini: incakuba ibotshelelwe kumzimba wemela, okanye intloko yemela ibotshelelwe kumzimba wemela.