Yenza mfutshane uMjikelo wakho weMveliso

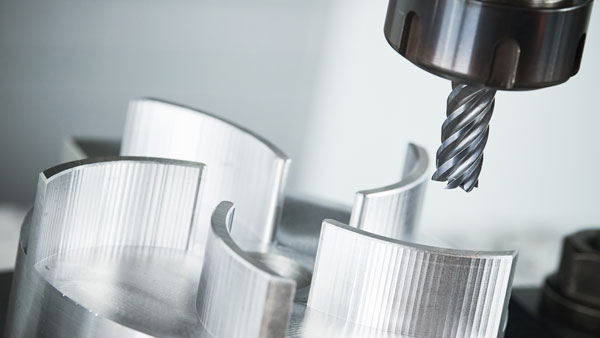

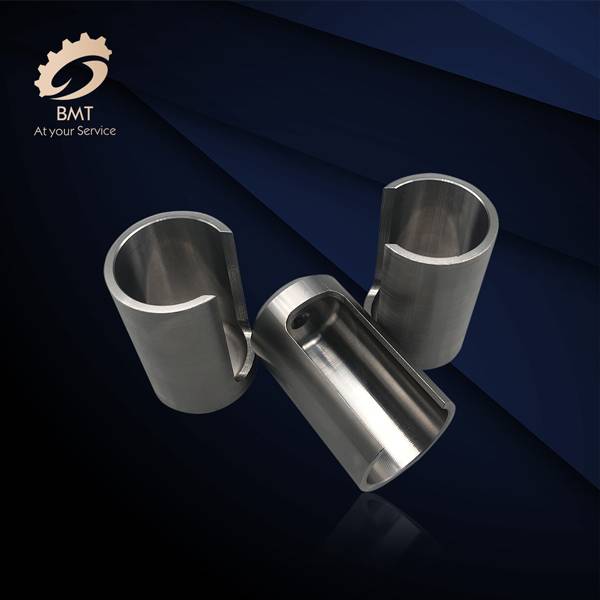

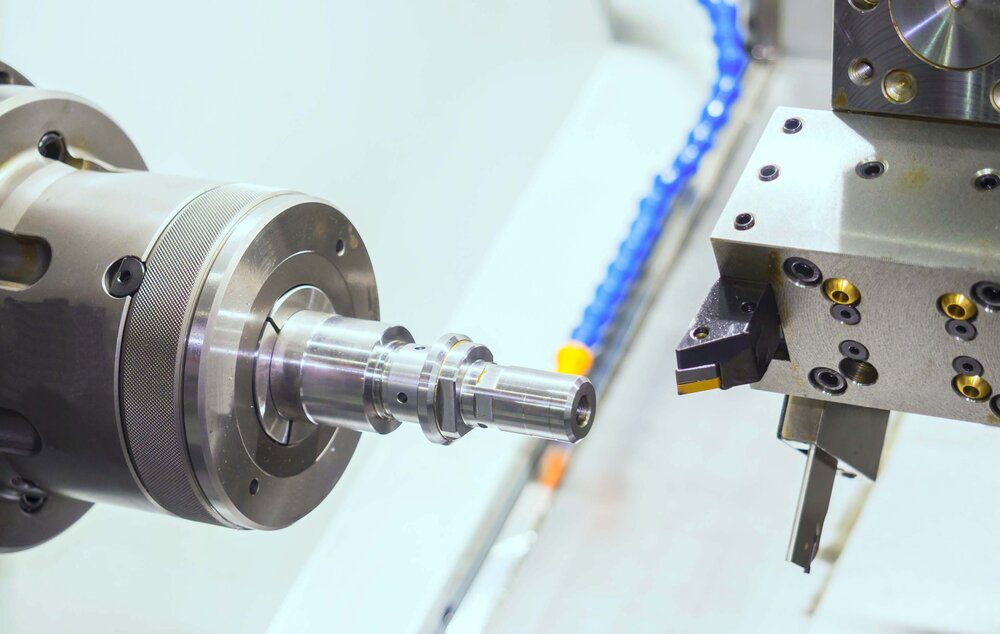

Obu buchule bokuvelisa ngumatshini osebenza ngokuzeleyo osebenzisa isoftware yokwenziwa kwekhompyutha kunye noyilo oluncediswa yikhompyuter. Kwiindawo ezinoyilo olulula, umqhubi unokufaka ngokuthe ngqo iinkqubo zomyalelo kumatshini. Kodwa kuyilo olunzima ngakumbi, umzobo weCAM okanye weCAD kufuneka wenziwe kuqala kwaye uhlanganiswe kwinkqubo. Enye indlela kukusebenzisa oomatshini bokuMeta ngoLungelelaniso (CMMs) ukwenza imephu ngokwasemzimbeni imiyalelo yoyilo kwisixokelelwano. Isoftware iya kudala kwaye ibonelele ngamanyathelo afunekayo kumatshini ngokuzenzekelayo ukwenza iindawo esizidingayo.

Kukho indawo encinci yempazamo kuba umatshini uya kulandela imiyalelo phantsi kweleta ukwenza imveliso. Eyona nto ingcono kukuba lo msebenzi uphinda-phinda-phinda, ovumela ukuveliswa ngokukhawuleza kwamalungu afanayo.

Ukusetyenziswa kwangaphambili koomatshini be-CNC bayacotha kwaye baqeshwe kuphela kwimveliso ephezulu. Ngoku, kwi-BMT, iteknoloji iphuculwe kakhulu. Ukusebenzisa isoftware entsonkothileyo kunye nezixhobo, ivumela ukudityaniswa ngokuthe ngqo kweemodeli ezenziwe ngekhompyuter kwinkqubo yenkqubo ukuba ikhawuleze ngakumbi. Oku kukwavumela ukusebenzisa iinkonzo zomatshini ze-CNC kwiimfuno zevolumu ephantsi ukuba zifikeleleke kwaye zisebenziseke.

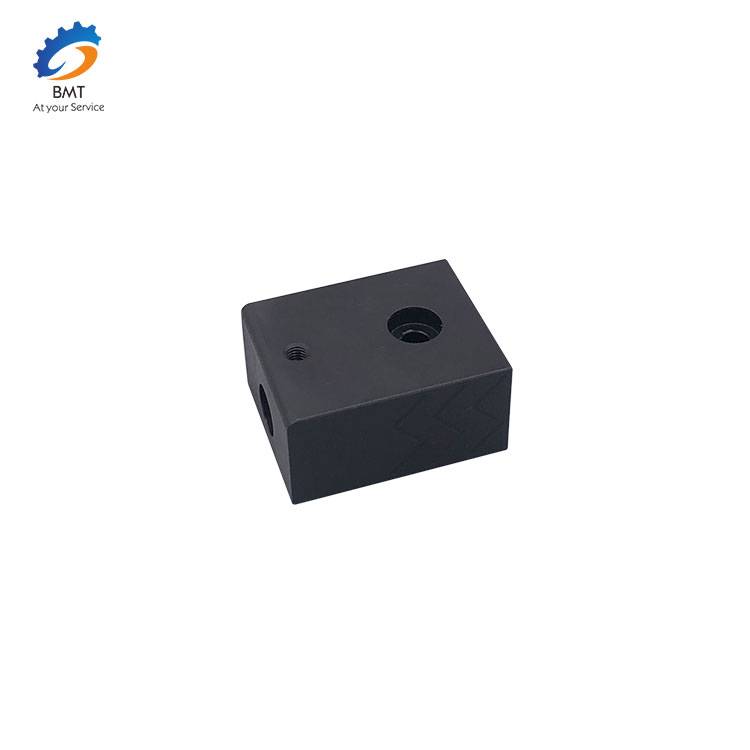

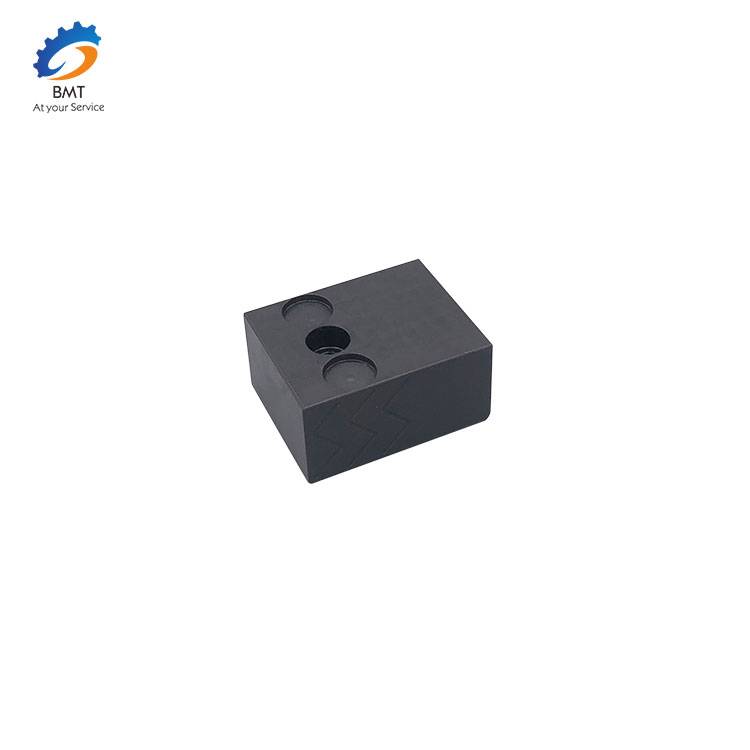

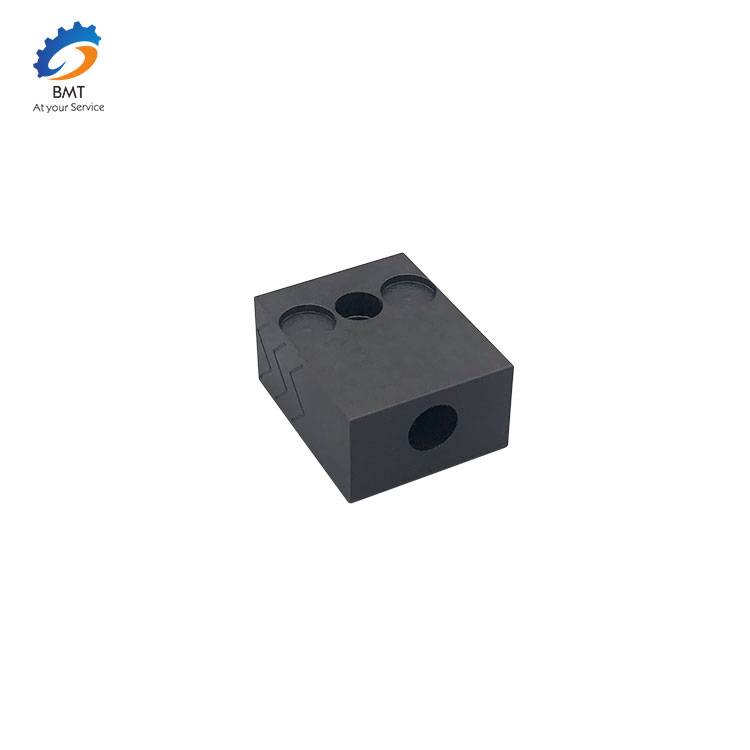

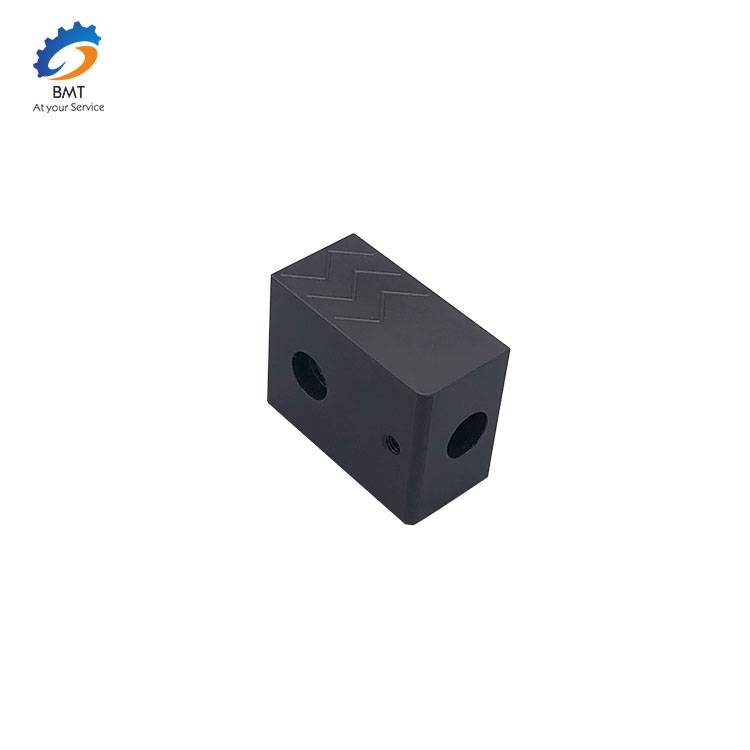

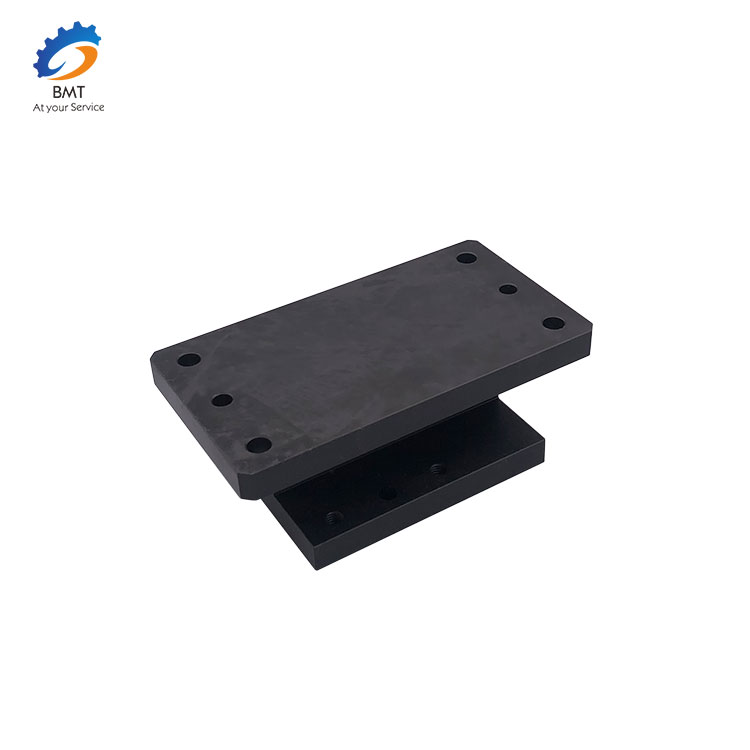

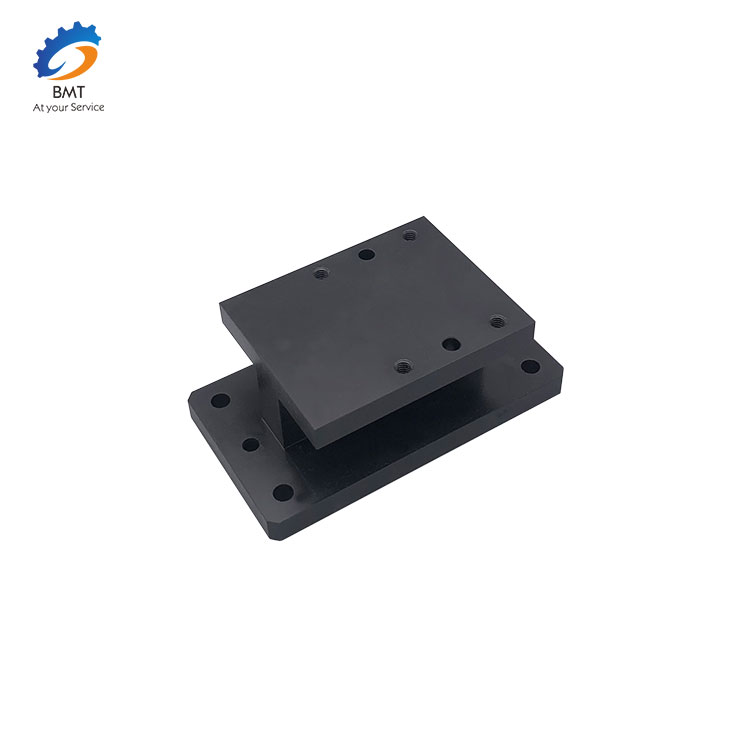

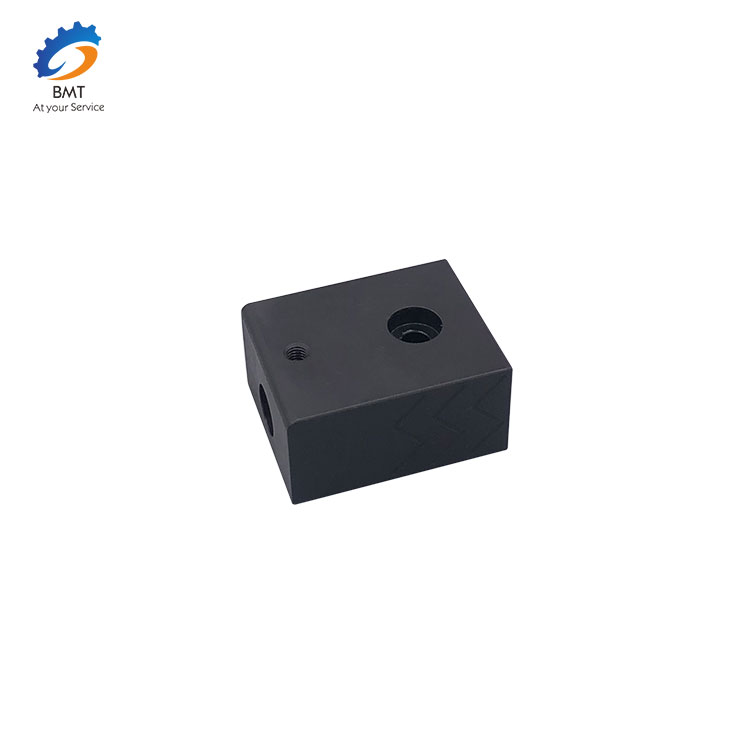

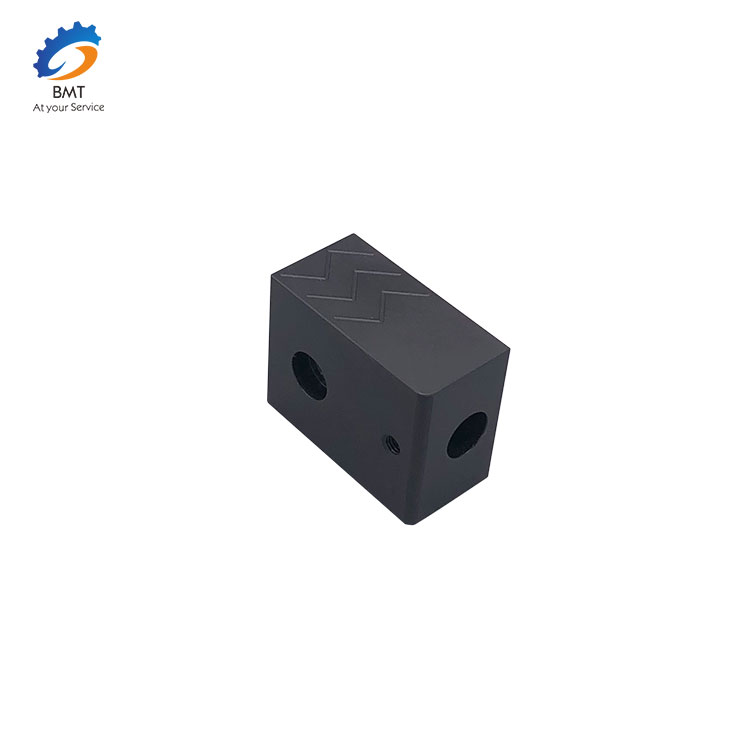

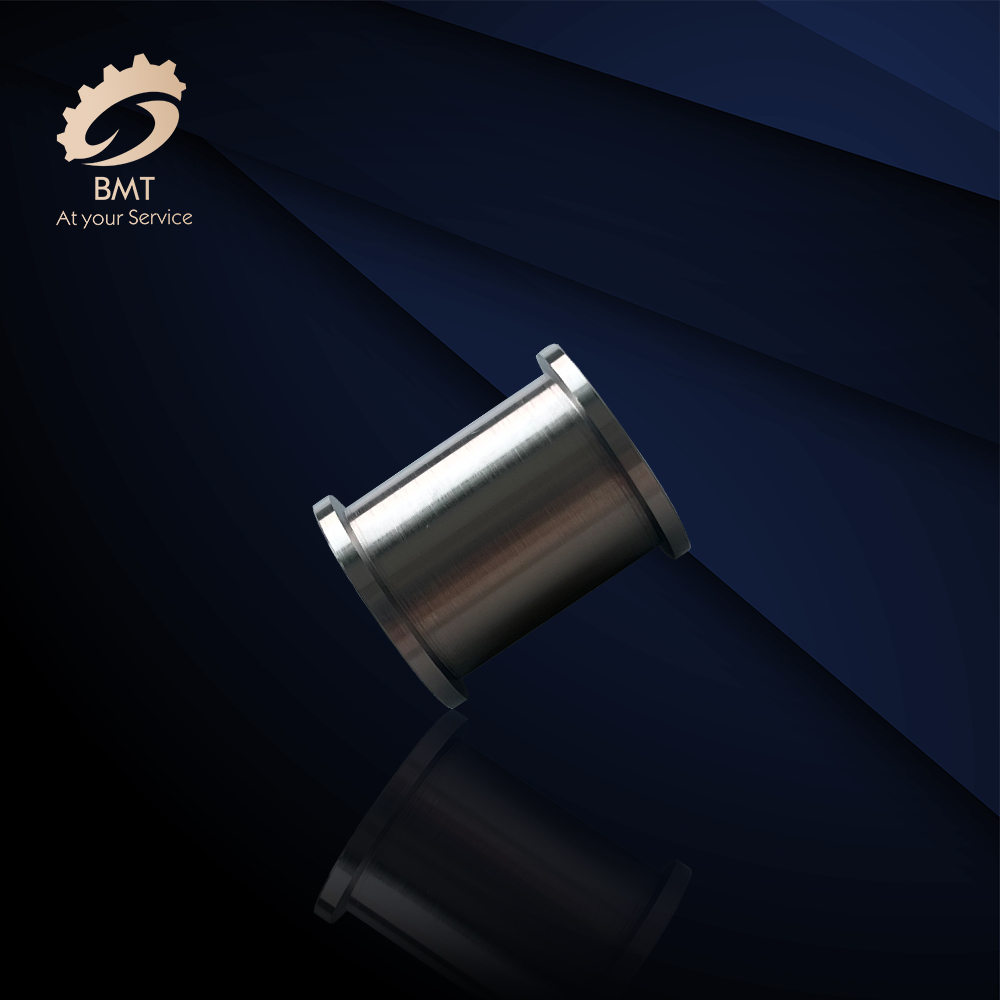

Kungakhathaliseki ukuba weyiphi imboni okanye yintoni imfuneko yakho, ngokusetyenziswa kweenkonzo zethu eziphezulu ze-CNC zomatshini, sinokwenza iiprototypes, ii-odolo zebhetshi ezincinci, kunye nokuveliswa kwevolumu ephantsi. Inkampani yethu idibanisa ukusetyenziswa kwetekhnoloji yokusika, oomatshini abaphambili, kunye neenjineli ezinetalente kwaye sinokuzisa iimveliso ukuba zigqithise ubulindele. Oomatshini be-CNC esinabo banokumelana neemeko ezigqithisileyo kunye neemeko zezicelo ezininzi phantse kuwo onke amashishini.

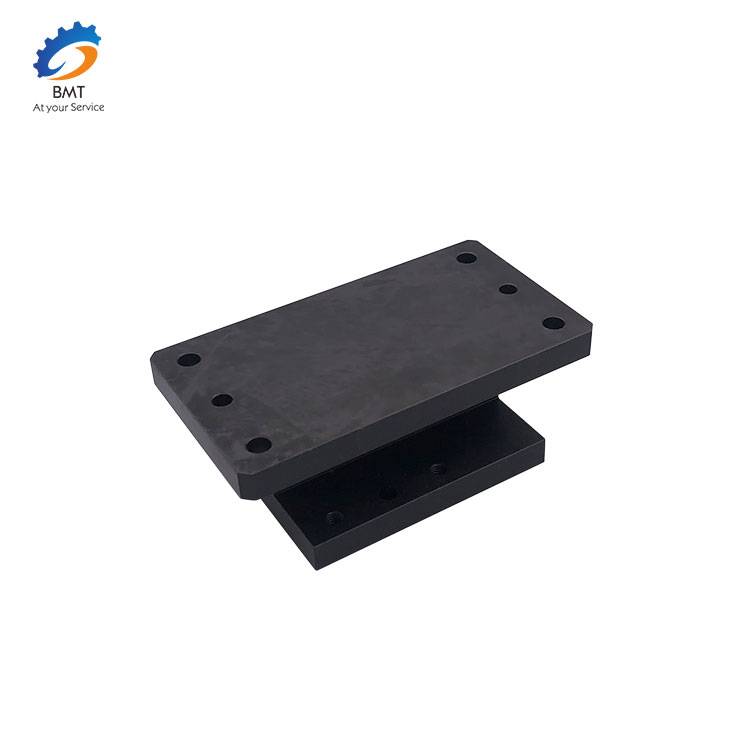

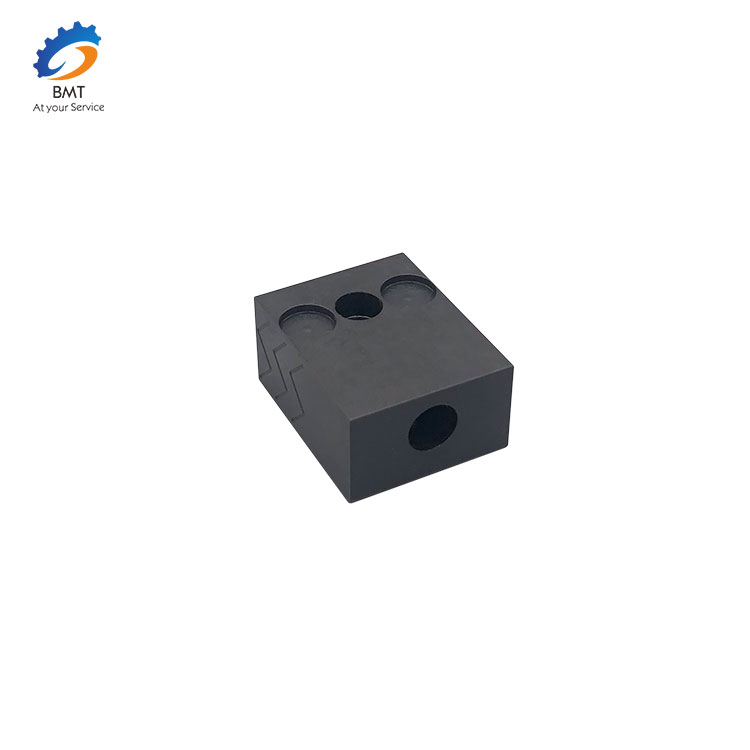

Iintsimbi kunye nezixhobo zePlastiki

Iintsimbi kunye nezixhobo zeplastiki esiqhele ukuzisebenzisa zidweliswe ngolu hlobo lungezantsi kwaye unokukhetha njengoko ufuna:

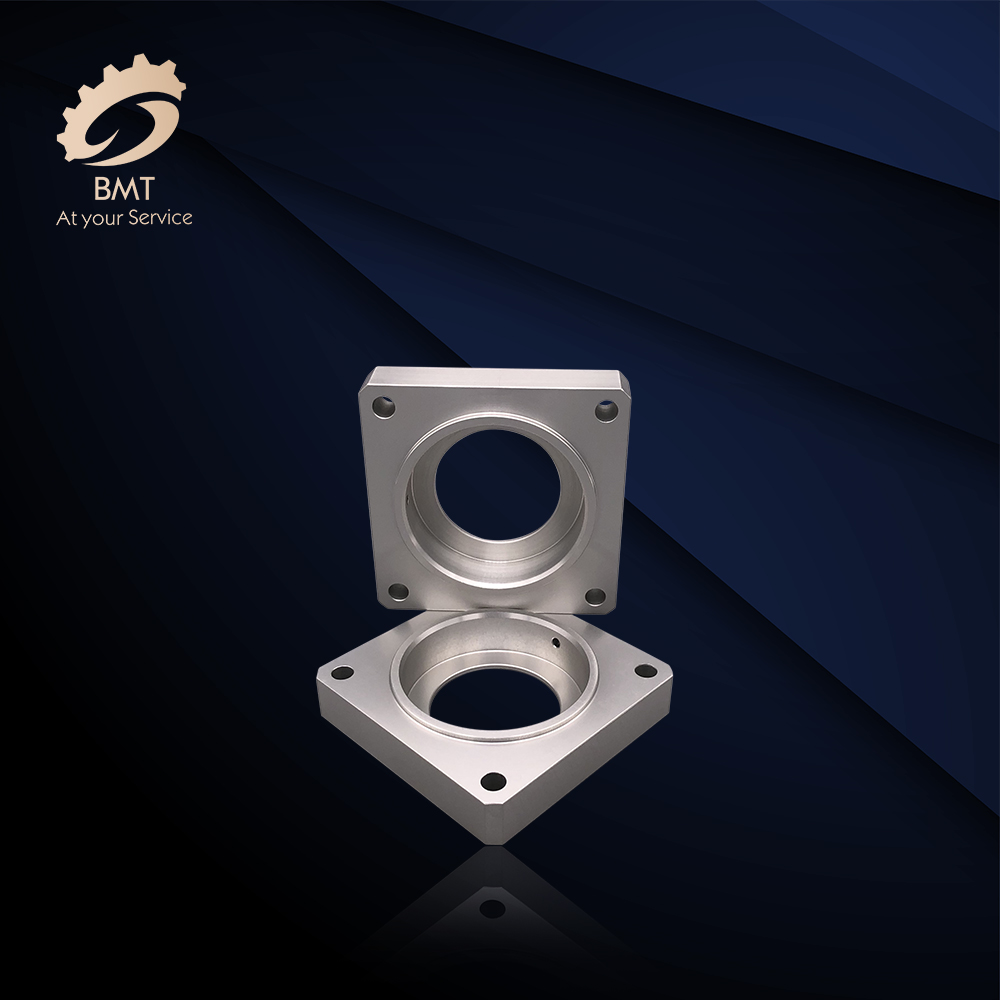

| IIMETALI | UKUNYAMEZELA | AMALUNGELO NEENQWELO | Gqibezela & UKUBONAKALA |

| Yenziwe ngentsimbi eshayinayo | +/- 0.005″ | Amandla aphezulu Ukuxhathisa okuPhakamileyo koMhlwa Ukuwelda okuphezulu | Ukugqitywa koMatshini oMgangatho kunye nomthengi wenkangeleko izicelo, ezifana ne-plating, i-anodizing, ukuqhushumba, njl. |

| Intsimbi yeCarbon | +/- 0.005″ | High Machinability Ukuwelda okuphezulu Inokwenziwa Ukuqina Ayinyangeki kuMhlwa | |

| Aluminiyam | +/- 0.005″ | Amandla aphezuluAmandla aphezulu Ubunzima obuphantsi High Machinability Ixabiso eliphantsi | |

| Ubhedu | +/- 0.005″ | Amandla aphezulu Ubunzima obuphantsi High Machinability Ixabiso eliphantsi |

| IIplastiki | UKUNYAMEZELA | AMALUNGELO NEENQWELO | Gqibezela & UKUBONAKALA |

| HDPE | +/- 0.008″ | Amandla eMpembelelo ePhakathi Ubhetyebhetye | Ukugqitywa koMatshini oMgangatho |

| PC | +/- 0.008″ | I-Medium Tensile Amandla empembelelo ephezulu Ugcina iiPropati Ngaphezu kwamaqondo obushushu Ukucaca okuphezulu kwe-Optical | |

| ABS | +/- 0.008″ | I-Medium Tensile Amandla empembelelo ephezulu Isigqubuthelo soMbane High Machinability Ixabiso eliphantsi | |

| acrylic | +/- 0.008″ | Amandla Okuqina aphezulu Inokugudiswa | |

| Inayiloni | +/- 0.008″ | High Tensile Amandla eMpembelelo ePhakathi Ugcina iiPropati Ngaphezu kwamaqondo obushushu | |

| Delrin | +/- 0.008″ | I-Medium Tensile Amandla eMpembelelo ePhakathi Ubambe Ukunyamezelwa koMatshini kakuhle Ukunxiba Okulungileyo kunye noKuxhathisa ukuFatigue | |

| I-ULTEM | +/- 0.008″ | Amandla Okuqina aphezulu Ubushushu bokusebenza obuphezulu Isigqubuthelo soMbane Ukucaca okuphezulu kwe-Optical |

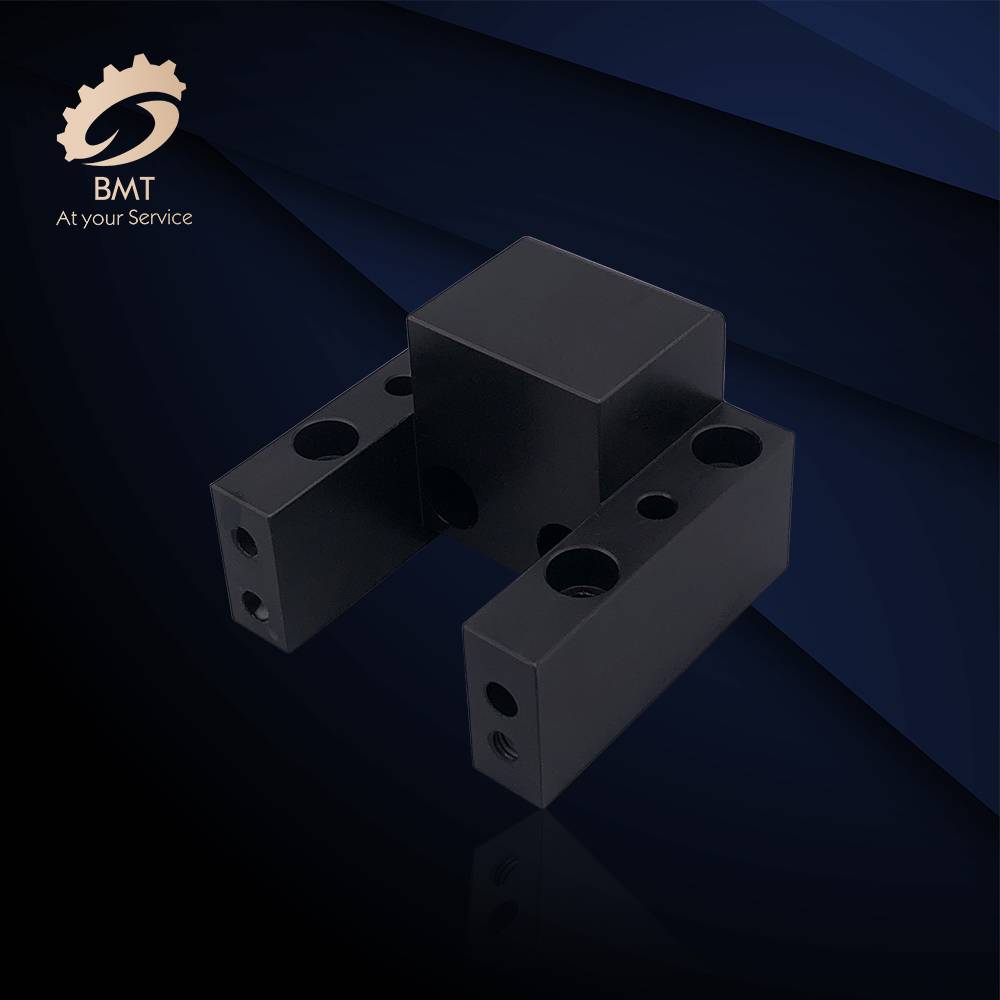

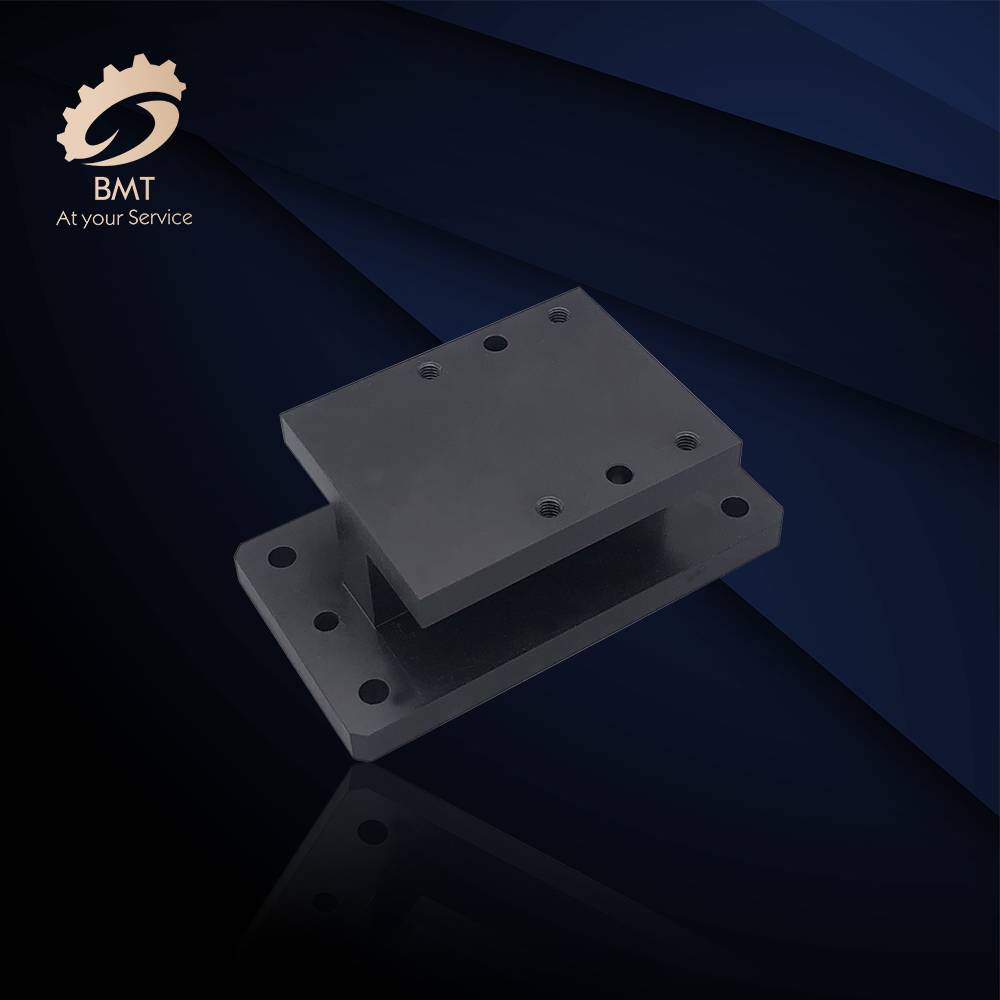

Ngaba uyafuna ukunciphisa umjikelo wemveliso kwaye unciphise iindleko zakho zemveliso?

I-BMT inesisombululo esisiso. Yenza lula inkqubo yokuvelisa kunye neenkonzo ze-CNC ze-machining, ezinokukunceda ukukhawulezisa ukuveliswa kwamalungu amakhulu omatshini kunye nenqanaba eliphezulu lokuchaneka kunye nokuchaneka.

Kwimveliso yanamhlanje, ukuthengiselana ngaphandle yeyona nto iphambili. I-BMT inokukubonelela ngomatshini okhawulezayo we-CNC ngokweemfuno zakho ezithile. Konke okufuneka ukwenze kukuthumela iifayile zeCAD okanye uphonsa umbuzo kwi-imeyile yethu yoqhagamshelwano. Sikubonelela ngekowuti ekhawulezayo nesimahla kwiinkonzo zobuchwephesha be-CNC kwaye ufumane iindawo ezinomatshini zicutshungulwe ngelona xesha lifutshane linokwenzeka.