Inkqubo yokuSebenza ye-CNC

Ngokucokisekileyo khangela iisixhobo somatshiningaphambi kokuqala, kubandakanywa nokuhlolwa kwendlela yokusebenza, izixhobo zombane, i-magnetic chuck kunye nezinye izixhobo. Emva kokuhlolwa, yithambise. Emva kokuthambisa, qhuba uvavanyo kwaye uqinisekise ukuba yonke into ikwimeko entle ngaphambi kokusetyenziswa. Xa ucinezela i-workpiece, qaphela ukulungelelaniswa kwayo kunye nokudibanisa.

Isixhobo esingasebenziyo ngexesha lokusila siya kubangela iziphumo ezibi njengokubhabha, ukwenzakalisa abantu okanye ukutyumza ivili lokusila. Xa uqala ukusebenza, sebenzisa uhlengahlengiso lwezandla ukwenza ivili lokusila lisondele kancinci kwindawo yokusebenza. Ukutya kokuqala kufuneka kube kuncinci, kwaye amandla amaninzi awavumelekanga ukukhusela ivili lokusila ukuba lingangqubani. Xa kukho imfuneko yokulawula isindululo esibuyiselayo sebhentshi yokusebenzela ngesithinteli, iya kulungiswa ngokuchanekileyo ngokweukusilaubude bomsebenzi womsebenzi, nesivingco soqiniselwe siqine.

Xa utshintsha ivili lokugaya, ukubonakala kufuneka kuhlolwe kuqala ukuze kubonwe ukuba akukho monakalo, kwaye ivili lokugaya liya kubethelwa ngesando somthi okanye intonga. Isandi siya kucaca kwaye sicace ngaphandle kweentanda. Xa ufaka ivili lokugaya, kufuneka lihlanganiswe ngokweendlela ezichaziweyo kunye neemfuno. Emva kwe-static balanceukugunyazisa, iya kufakwa kwaye ivavanywe. Ingasetyenziswa kuphela emva kokuba yonke into iqhelekile.

Abasebenzi baya kunxiba iiglasi zokhuseleko ngexesha lomsebenzi, kwaye ivili lokugaya liya kucuthwa ngendlela elungeleleneyo ukuthintela impembelelo. Ukulinganisa i-workpiece, lungisa okanye usule isixhobo somatshini emva kokuvala. Xa usebenzisa i-magnetic chuck, umphezulu wedisk kunye ne-workpiece iyakusulwa, iqiniswe kwaye ifunxe ngokuqinileyo.

Ukuba kuyimfuneko, isithinteli singongezwa ukuthintelaumsebenziukusuka ekutshintsheni okanye ukubhabha ngaphandle. Ingqalelo iya kuhlawulwa ekufakeni isigqubuthelo esikhuselayo sevili lokusila okanye i-baffle yesixhobo somatshini, kwaye icala lesikhululo liya kujikeleza umphambili wevili lokusila ngesantya esiphezulu.

Thumela umyalezo wakho kuthi:

-

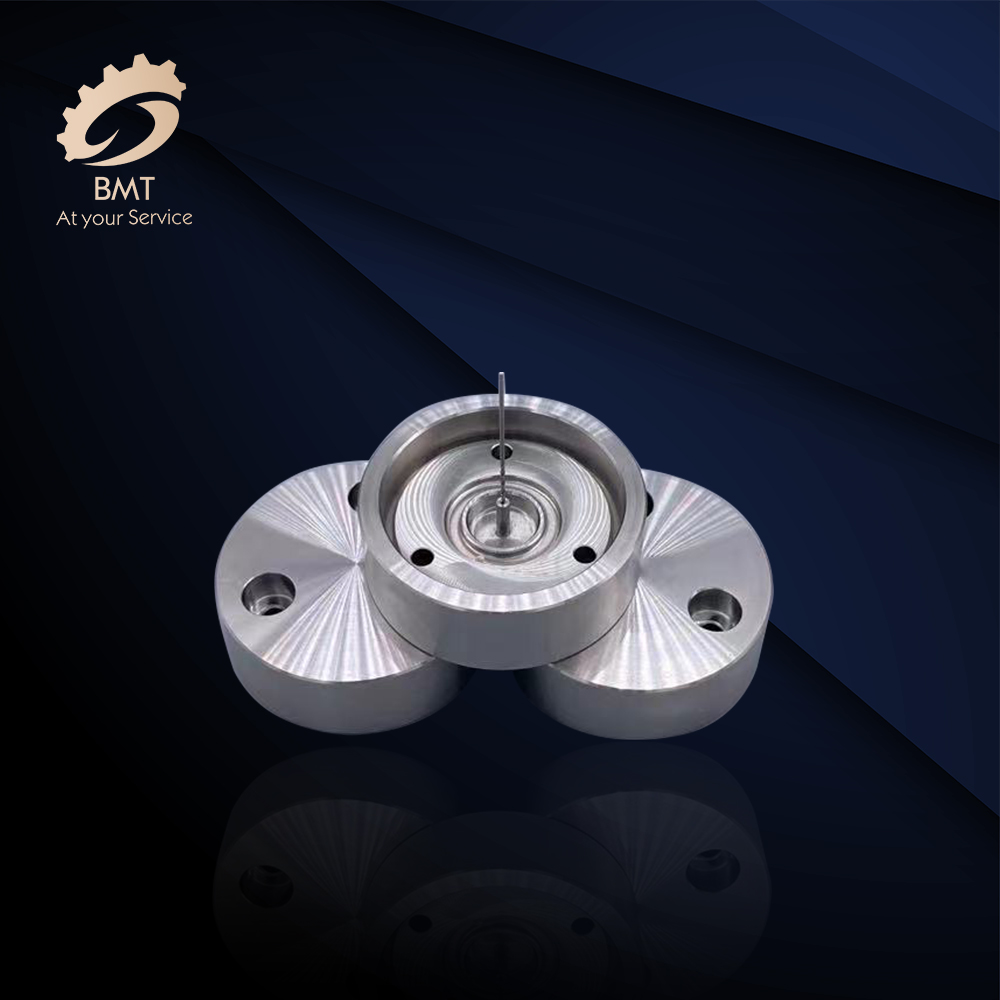

Aluminiyam CNC Machining Parts

-

I-Aluminiyam yePhepha leMetal Fabrication

-

Axis High Precision CNC Machining Parts

-

Izahlulo zoomatshini be-CNC base-Itali

-

CNC Machining Aluminiyam iinxalenye

-

Auto Parts Machining

-

I-Titanium Alloy Forgings

-

I-Titanium kunye ne-Titanium Alloy Fittings

-

I-Titanium kunye ne-Titanium Alloy Forgings

-

Iingcingo zeTitanium kunye neTitanium Alloy

-

Iibha zeTitanium

-

Imibhobho yeTitanium engenamthungo/iiThubhu

-

I-Titanium Welded imibhobho / iiThubhu