Izixhobo zoKhetho lweCNC Machining

Umgaqo-siseko wokukhetha izixhobo ze-CNC

Ubomi besixhobo bunxulumene ngokusondeleyo nokusika umthamo. Xa uqulunqa iiparamitha zokusika, ubomi besixhobo esifanelekileyo kufuneka bukhethwe kuqala, kwaye ubomi besixhobo obufanelekileyo kufuneka bumiselwe ngokwenjongo yokuphucula. Ngokuqhelekileyo yahlulahlulwe kobona bomi besixhobo sokuvelisa imveliso kunye neyona xabiso liphantsi ubomi besixhobo, eyokuqala imiselwa ngokwenjongo yeyona yure incinci yomnye umntu, kwaye le yokugqibela imiselwa ngokwenjongo yeendleko zenkqubo ephantsi.

Xa ukhetha izixhobo, unokuqwalasela la manqaku alandelayo ngokobunzima besixhobo, iindleko zokuvelisa kunye nokugaya. Ubomi bezixhobo eziyinkimbinkimbi kunye nezichanekileyo eziphezulu kufuneka zibe phezulu kunezo zixhobo ezinqamlekileyo. Kwizixhobo ze-indexable machine clamp, ngenxa yexesha elifutshane lokutshintsha isixhobo, ukwenzela ukunika umdlalo opheleleyo ekusebenzeni kwayo kokusika kunye nokuphucula ukusebenza kakuhle kwemveliso, ubomi besixhobo bunokukhethwa ukuba bube buphantsi, ngokubanzi i-15-30min. Kwizixhobo ezininzi, izixhobo zomatshini wemodyuli kunye nezixhobo zomatshini ezizenzekelayo kunye nokufakwa kwesixhobo esiyinkimbinkimbi, utshintsho lwesixhobo, kunye nokulungiswa kwesixhobo, ubomi besixhobo kufuneka bube phezulu, kwaye ukuthembeka kwesixhobo kufuneka kuqinisekiswe ngokukodwa.

Xa imveliso yenkqubo ethile kwiworkshop inciphisa ukuphuculwa kwemveliso yeworkshop iyonke, ubomi besixhobo senkqubo kufuneka bukhethwe ngaphantsi. Xa ixabiso lesityalo sonke ngexesha leyunithi yenkqubo ethile lilikhulu kakhulu, ubomi besixhobo kufuneka bukhethwe Phantsi. Xa ugqiba iinxalenye ezinkulu, ukwenzela ukuba kuqinisekiswe ukuba ubuncinane enye idlula igqityiwe, kwaye ugweme ukutshintsha isixhobo phakathi kokusika, ubomi besixhobo kufuneka bugqitywe ngokuchaneka kwenxalenye kunye nobunzima bomhlaba. Xa kuthelekiswa neendlela eziqhelekileyo zokulungiswa kwesixhobo somatshini, umatshini weCNC ubeka phambili iimfuno eziphezulu kwizixhobo zokusika.

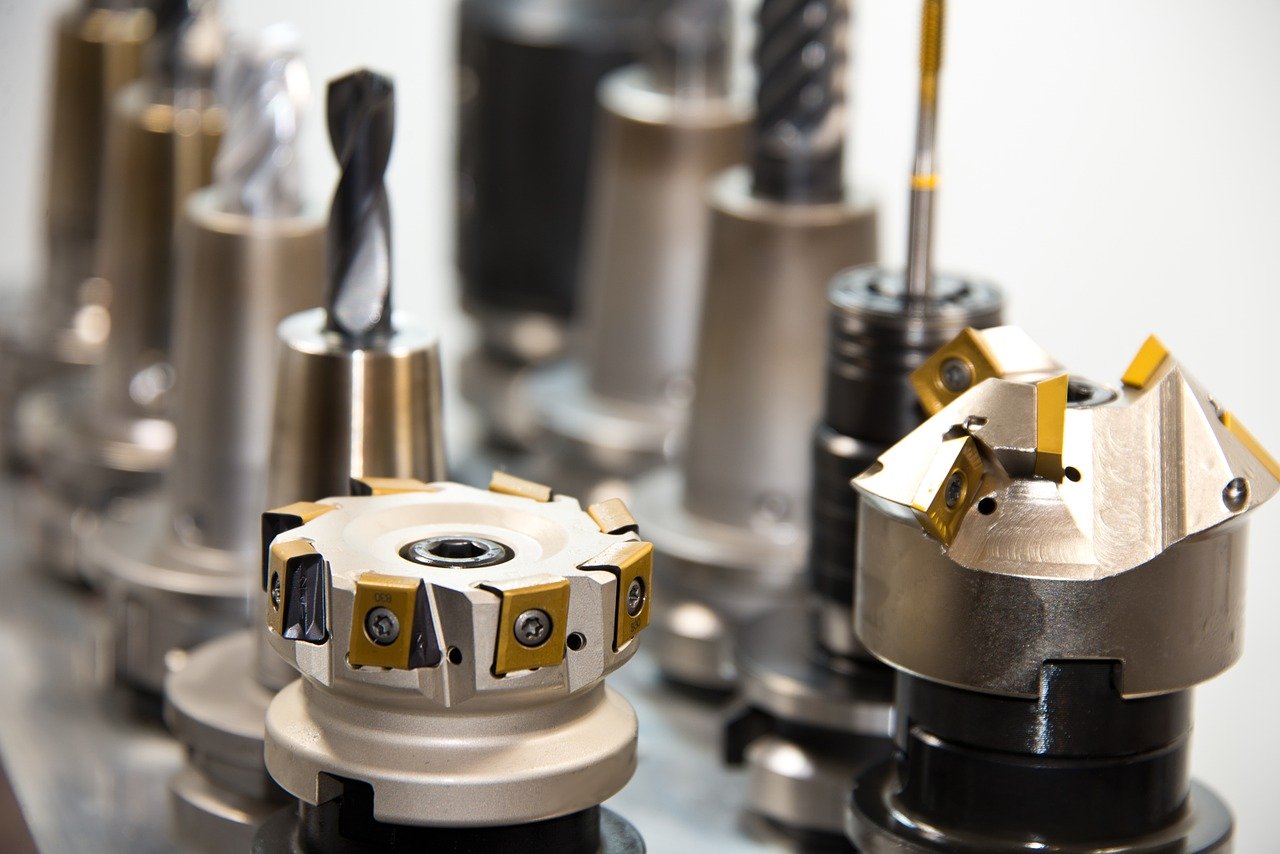

Ayifuni kuphela umgangatho olungileyo kunye nokuchaneka okuphezulu, kodwa ifuna uzinzo lwe-dimensional, ukuqina okuphezulu, kunye nofakelo olulula kunye nohlengahlengiso. Ukuhlangabezana neemfuno eziphezulu zokusebenza kwezixhobo zoomatshini be-CNC. Izixhobo ezikhethiweyo kwizixhobo zomshini we-CNC zihlala zisebenzisa izixhobo zesixhobo ezifanelekileyo ukusika isantya esiphezulu (njengensimbi enesantya esiphezulu, i-ultra-fine-grained cemented carbide) kunye nokusetyenziswa kwe-indexable inserts.

Khetha izixhobo zokuJika kwe-CNC

Izixhobo ezisetyenziswa ngokuqhelekileyo ze-CNC zokuguqula zihlulwe zibe ziintlobo ezintathu: izixhobo zokubumba, izixhobo ezichongiweyo, izixhobo ze-arc kunye neentlobo ezintathu. Izixhobo zokuguqula ukubumba zikwabizwa ngokuba yi-prototype yokujika izixhobo, kwaye imilo ye-contour yamacandelo omatshini igqitywe ngokupheleleyo ngokuma kunye nobukhulu becala lokusika isixhobo sokuguqula. Kwinkqubo yokuguqula i-CNC, izixhobo eziqhelekileyo zokuguqula i-arc zibandakanya izixhobo ezincinci zokujika i-radius arc, izixhobo zokujika ezingezona uxande kunye nezixhobo zokuthunga. Kwi-machining ye-CNC, isixhobo sokuguqula ukwenza kufuneka sisetyenziswe kancinci kangangoko okanye hayi. Isixhobo sokuguqula esicacileyo sisixhobo sokuguqula esibonakaliswe ngomgca ochanekileyo wokusika.

Incam yolu hlobo lwesixhobo sokuguqula iqulethwe ngamacandelo aphambili kunye nesibini, njengezixhobo ze-900 zokuguqula zangaphakathi nangaphandle, izixhobo zokuguqula ubuso ngasekhohlo nasekunene, izixhobo zokuguqula i-grooving (ukusika), kunye nemida eyahlukeneyo yokusika yangaphandle nangaphakathi. ama-chamfers amancinci amancinci. Isixhobo sokuguqula umngxuma. Indlela yokukhethwa kweeparameters zejometri yesixhobo sokujika esichongiweyo (ingakumbi i-angle yejometri) ngokusisiseko iyafana neyokujika okuqhelekileyo, kodwa iimpawu ze-CNC machining (ezifana nomzila womatshini, ukuphazamiseka komatshini, njl. njl.) kufuneka ziqwalaselwe ngokubanzi. , kunye nencam yesixhobo ngokwayo kufuneka ithathwe njengamandla.

Okwesibini sisixhobo sokuguqula i-arc. Isixhobo sokuguqula i-arc sisixhobo sokuguqula esibonakaliswe yi-arc-shaped cut edge ene-roundness encinci okanye impazamo yeprofayili yomgca. Inqaku ngalinye le-arc edge yesixhobo sokuguqula isicatshulwa sesixhobo sokuguqula i-arc. Ngokuhambelanayo, indawo yokumisa isixhobo ayikho kwi-arc, kodwa kumbindi we-arc. Isixhobo sokuguqula i-arc singasetyenziselwa ukuguqula indawo yangaphakathi nangaphandle, kwaye ifaneleke ngokukodwa ukuguqula iindawo ezahlukeneyo ezidibeneyo (concave) zokwenza. Xa ukhetha i-radius ye-arc yesixhobo sokuguqula, kufuneka kuthathelwe ingqalelo ukuba i-arc radius yomgca wokusika wesixhobo sokujika samanqaku amabini kufuneka ibe ngaphantsi okanye ilingane ne-radius ye-curvature encinci kwi-concave concave yecandelo, ukuze ukunqanda ukomisa processing. Iradiyasi akufanele ikhethwe incinci kakhulu, kungenjalo ayiyi kuba nzima ukuyivelisa kuphela, Isixhobo sokujika sinokonakaliswa ngenxa yamandla eengcebiso ezibuthathaka okanye amandla okutshatyalaliswa kobushushu bomzimba wesixhobo.