CNC Machining Iimpazamo

Iphutha lejometri ye-fixture fixture kukwenza i-workpiece ilingane nesixhobo kunye nesixhobo somatshini esinendawo echanekileyo, ngoko ke impazamo yejometri yephutha lokulungisa i-machining (ingakumbi impazamo yendawo) inempembelelo enkulu.

Impazamo yokubeka ubukhulu becala ibandakanya impazamo yedatum yempazamo kunye nempazamo engachanekanga yokwenziwa kokumisa izibini. Xa i-workpiece icutshungulwa kwisixhobo somatshini, kuyimfuneko ukukhetha inani lezinto zejometri kwi-workpiece njenge-datum yokubeka ukucubungula. Ukuba uluhlu lwedatha olukhethiweyo lokumisa kunye noyilo lwedatha (idatha esetyenzisiweyo ukumisela ubungakanani bomphezulu kunye nendawo kwindawo yomzobo) azingqinelani, iya kuvelisa impazamo yokungafani kwedatha. Umphezulu wendawo yokusebenzela kunye nendawo yokubeka indawo ye-fixture yenza iperi yokubeka kunye. Olona tshintsho luphezulu lwesikhundla sesixhobo sokusebenza esibangelwa kukwenziwa ngendlela engachanekanga kwesibini esikuyo kunye nomsantsa wokukhwelana phakathi kwesibini esichongwayo sibizwa ngokuba yimpazamo yokuvelisa engalunganga yeperi yokufumana indawo. Impazamo yokuvelisa impazamo yokumisa isibini inokuveliswa kuphela xa kusetyenziswe indlela yokulungelelanisa, kodwa kungekhona kwindlela yokusika isilingo.

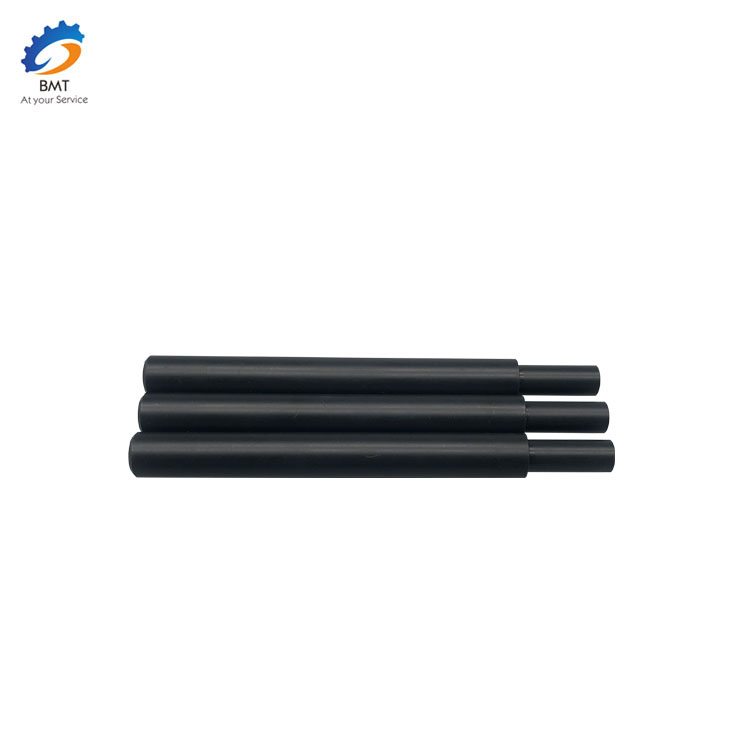

Inkqubo yenkqubo yokuguqulwa kwempazamo yobunzima bomsebenzi: inkqubo yenkqubo ukuba ukuqina kwesixhobo sokusebenza ngokunxulumene nesixhobo somatshini, isixhobo, ukulungiswa kuphantsi ngokwentelekiso, phantsi kwesenzo samandla okusika, i-workpiece ngenxa yokungabikho kokuqina okubangelwa kukuguqulwa kwesixhobo.impazamo yomatshiniinkulu ngokwentelekiso. Ukuqina kwesixhobo: ukuqina kwesixhobo sokujika setyhula yangaphandle kwindlela eqhelekileyo (y) yolwalathiso lwe-machining surface bukhulu kakhulu, kwaye ukuguqulwa kwayo akunakunakwa. Ukubhobhoza umngxuma wangaphakathi kunye nobubanzi obuncinci, ukuqina kwebha yesixhobo kubi kakhulu, ukuguqulwa kwamandla kwebha yesixhobo kunempembelelo enkulu ekuchanekeni komatshini womngxuma.

Ukuqina kwezixhobo zesixhobo somatshini: izixhobo zesixhobo somatshini zenziwe ngamacandelo amaninzi. Ukuza kuthi ga ngoku, akukho ndlela ifanelekileyo kunye nelula yokubala yokuqina kwezixhobo zesixhobo somatshini. Okwangoku, ubukhulu becala kumiselwa ngendlela yovavanyo. Izinto ezichaphazela ukuqina kwezixhobo zesixhobo somatshini ziquka ukuguqulwa koqhagamshelwano lomphezulu odibeneyo, amandla okubetha, iindawo eziphantsi kunye nokukhutshwa.

Iphutha lejometri yesixhobo nasiphi na isixhobo kwinkqubo yokusika ayinakuphepheka ukuvelisa ukunxiba, kwaye ngaloo ndlela kubangele ukuba ubungakanani kunye nokuma kwendawo yokusebenza itshintshe. Impembelelo yempazamo yejiyometri yesixhobo kwimpazamo yomatshini iyahluka kunye neentlobo ezahlukeneyo zezixhobo: xa usebenzisa izixhobo zokusika ubungakanani obusisigxina, impazamo yokuvelisa isixhobo iya kuchaphazela ngokuthe ngqo ukuchaneka komatshini womsebenzi; Nangona kunjalo, kwisixhobo esiqhelekileyo (njengesixhobo sokuguqula), impazamo yokuvelisa ayinayo impembelelo ngqo kwimpazamo yomatshini.