I-Titanium Machining Ubunzima

(1) I-deformation coefficient incinci:

Olu luphawu olucacileyo kumatshini we-titanium alloy materials. Kwinkqubo yokusika, indawo yoqhagamshelwano phakathi kwe-chip kunye ne-rake face inkulu kakhulu, kwaye i-stroke ye-chip ebusweni be-rake yesixhobo ikhulu kakhulu kuneyona nto eqhelekileyo. Ukuhamba okunjalo kwexesha elide kuya kubangela ukugqoka izixhobo ezinzulu, kunye neFriction nayo iyenzeka ngexesha lokuhamba, okwandisa ukushisa kwesixhobo.

(2) Ubushushu obuphezulu bokusika:

Ngakolunye uhlangothi, i-coefficient encinci ye-deformation ekhankanywe ngasentla iya kukhokelela kwinxalenye yokunyuka kweqondo lokushisa. Inkalo ephambili yobushushu obuphezulu bokusika kwinkqubo yokusika i-titanium alloy kukuba i-thermal conductivity ye-titanium alloy incinci kakhulu, kwaye ubude boqhagamshelwano phakathi kwe-chip kunye ne-rake face yesixhobo bufutshane.

Ngaphantsi kwempembelelo yale miba, ukushisa okwenziwa ngexesha lenkqubo yokusika Kunzima ukuyihambisa ngaphandle, kwaye ikakhulu iqokelela kufuphi nencam yesixhobo, ebangela ukuba ukushisa kwendawo kuphakame kakhulu.

(3) I-thermal conductivity ye-titanium alloy iphantsi kakhulu:

Ubushushu obuveliswa ngokusikwa abupheli lula. Inkqubo yokuguqula i-titanium alloy yinkqubo yoxinzelelo olukhulu kunye noxinzelelo olukhulu, oluya kuvelisa ubushushu obuninzi, kwaye ukushisa okuphezulu okwenziwa ngexesha lokucubungula akukwazi ukusasazwa ngokufanelekileyo. Kwi-blade, iqondo lokushisa likhuphuka ngokukhawuleza, i-blade iyancipha, kwaye isixhobo sinxibe isantya.

Amandla athile emveliso ye-titanium alloy iphezulu kakhulu phakathi kwezinto zokwakha zetsimbi. Amandla ayo afaniswa nentsimbi, kodwa ubunzima bayo bungama-57% kuphela entsimbi. Ukongeza, iialloyi ze-titanium zineempawu zobunzima obuthile obuncinci, amandla aphezulu e-thermal, ukuzinza okuhle kwe-thermal kunye nokumelana nokubola, kodwa izixhobo ze-titanium alloy kunzima ukuzisika kwaye zisebenza ngokufanelekileyo. Ke ngoko, indlela yokoyisa ubunzima kunye nokusebenza okuphantsi kwe-titanium alloy processing ibisoloko iyingxaki engxamisekileyo ekufuneka isonjululwe.

Thumela umyalezo wakho kuthi:

-

Aluminiyam CNC Machining Parts

-

I-Aluminiyam yePhepha leMetal Fabrication

-

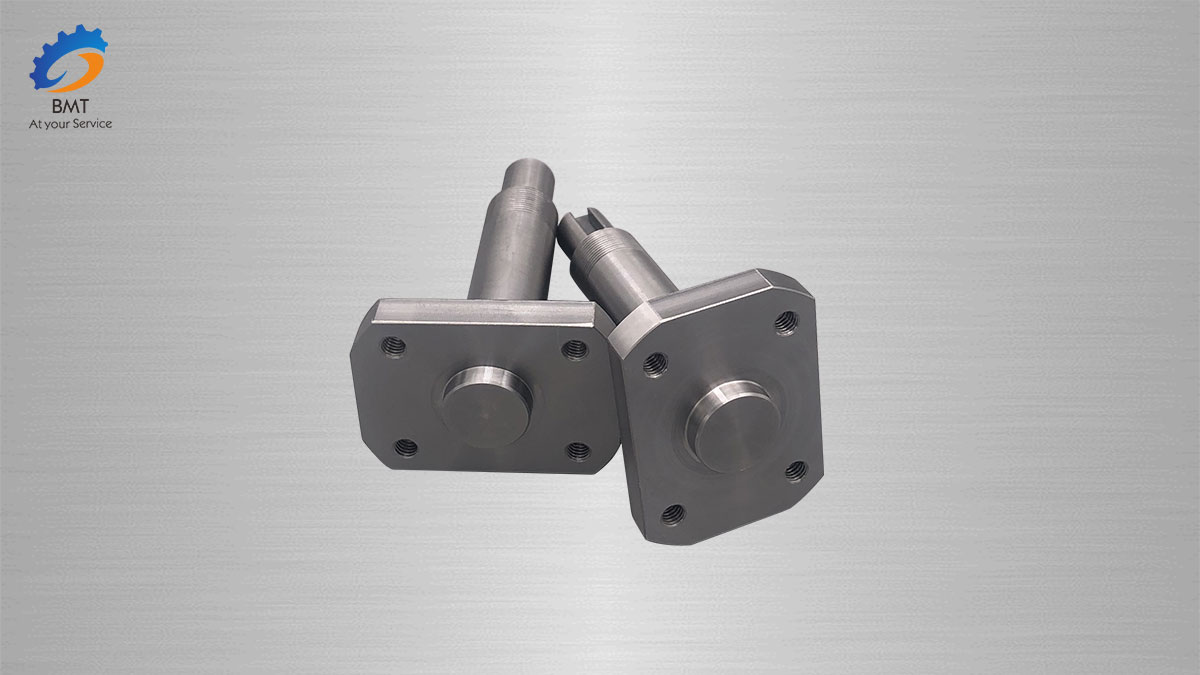

Axis High Precision CNC Machining Parts

-

Izahlulo zoomatshini be-CNC base-Itali

-

CNC Machining Aluminiyam iinxalenye

-

Auto Parts Machining

-

I-Titanium Alloy Forgings

-

I-Titanium kunye ne-Titanium Alloy Fittings

-

I-Titanium kunye ne-Titanium Alloy Forgings

-

Iingcingo zeTitanium kunye neTitanium Alloy

-

Iibha zeTitanium

-

Imibhobho yeTitanium engenamthungo/iiThubhu

-

I-Titanium Welded imibhobho / iiThubhu