I-Titanium Alloy CNC Machining

Xa ukuqina kwe-titanium alloy kukhulu kune-HB350, ukusika kunzima kakhulu, kwaye xa ingaphantsi kwe-HB300, kulula ukunamathela kwimela kwaye kunzima ukuyisika. Ngoko ke, ingxaki yokulungiswa kwe-titanium ingasombululwa kwi-blade. Ukunxiba kwe-groove yokufaka kwi-machining ye-titanium alloys kukunxitywa kwendawo yangasemva nangaphambili kwicala lobunzulu bokusika, okuhlala kubangelwa ngumaleko olukhuni oshiywe ngumatshini wangaphambili.

Ukusabela kweekhemikhali kunye nokusasazwa kwesixhobo kunye nezixhobo zokusebenza kwiqondo lokushisa elingaphezulu kwe-800 °C sesinye sezizathu zokwenza ukunxiba kwe-groove. Ngenxa yokuba ngexesha lenkqubo yomatshini, iimolekyuli ze-titanium ze-workpiece ziqokelela phambi kwe-blade kwaye "zifakwe kwi-welded" kwi-blade edge phantsi koxinzelelo oluphezulu kunye nobushushu obuphezulu, zenza umda owenziweyo.

Xa i-edge eyakhelweyo ikhupha umgca wokusika, ithatha i-carbide coating of the insert, ngoko ke i-titanium machining ifuna izinto ezikhethekileyo zokufaka kunye neejometri.

.

Kuyafaneleka ukukhankanya ukuba ekubeni i-titanium alloys ivelisa ukushisa okuphezulu ngexesha lokucutshungulwa, inani elikhulu le-high-pressure cutting fluid kufuneka litshizwe kwinqanaba lokusika ngexesha elifanelekileyo kwaye lichanekileyo ukususa ngokukhawuleza ukushisa. Kukwakho nezakhiwo ezizodwa zabasiki bemilling ezisetyenziselwa ngokukodwa ukusetyenzwa kwe-titanium alloy kwimarike namhlanje, ezilungele ngcono ukusetyenzwa kwe-titanium alloy.

Okwangoku, onke amazwe aphuhlisa iialloyi ezintsha ze-titanium ezinexabiso eliphantsi kunye nokusebenza okuphezulu, kwaye azabalazela ukwenza iialloyi ze-titanium zingene kwintsimi yemizi-mveliso yasekuhlaleni enesakhono esikhulu semarike. ilizwe lam nalo alizibambi iinzame zokuqhubela phambili kweli candelo.

Kukholelwa ukuba ngemigudu edibeneyo yazo zonke iingcali zoshishino, ukusetyenzwa kwee-alloys ze-titanium akusayi kuba yingxaki kwixesha elizayo, kodwa kuya kuba yintsimbi ebukhali kuphuhliso loshishino lwelizwe lam, ukoyisa imiqobo yophuhliso lwemveliso. ishishini lonke.

Thumela umyalezo wakho kuthi:

-

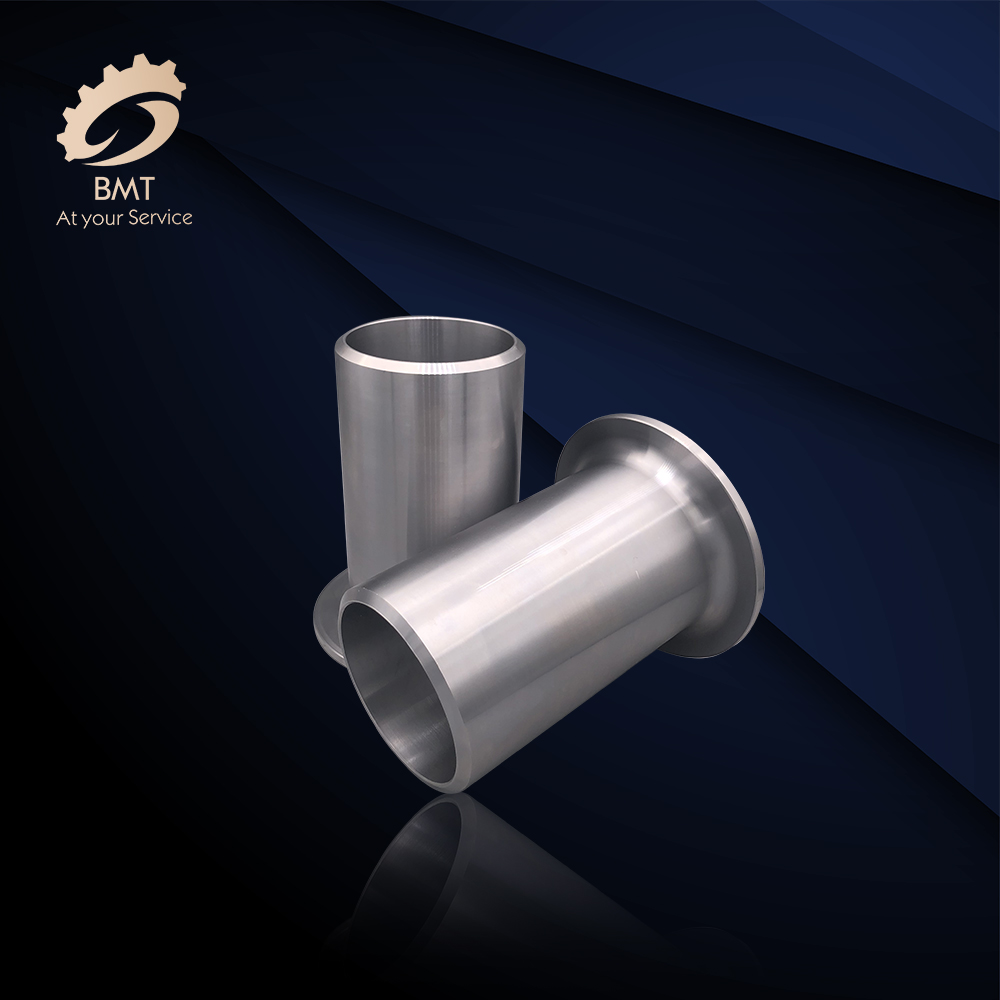

Aluminiyam CNC Machining Parts

-

I-Aluminiyam yePhepha leMetal Fabrication

-

Axis High Precision CNC Machining Parts

-

Izahlulo zoomatshini be-CNC base-Itali

-

CNC Machining Aluminiyam iinxalenye

-

Auto Parts Machining

-

I-Titanium Alloy Forgings

-

I-Titanium kunye ne-Titanium Alloy Fittings

-

I-Titanium kunye ne-Titanium Alloy Forgings

-

Iingcingo zeTitanium kunye neTitanium Alloy

-

Iibha zeTitanium

-

Imibhobho yeTitanium engenamthungo/iiThubhu

-

I-Titanium Welded imibhobho / iiThubhu