Iingcingo zeTitanium kunye neTitanium Alloy

I-titanium ecocekileyo yintsimbi emhlophe esiliva, eneempawu ezininzi ezintle. I-Titanium inoxinano lwe-4.54g/cm3, I-43% ilula kunentsimbi kwaye inzima kancinci kune-magnesium yensimbi eqaqambileyo. Kodwa amandla oomatshini aphantse alingane nentsimbi, yomelele ngokuphindwe kabini kune-aluminiyam kwaye yomelele ngokuphindwe kahlanu kune-magnesium. I-Titanium imelana nobushushu obuphezulu kwaye inendawo yokunyibilika ye-1942K, iphantse ibe yi-1000K ngaphezulu kwegolide kwaye iphantse ibe yi-500K ngaphezulu kwentsimbi.

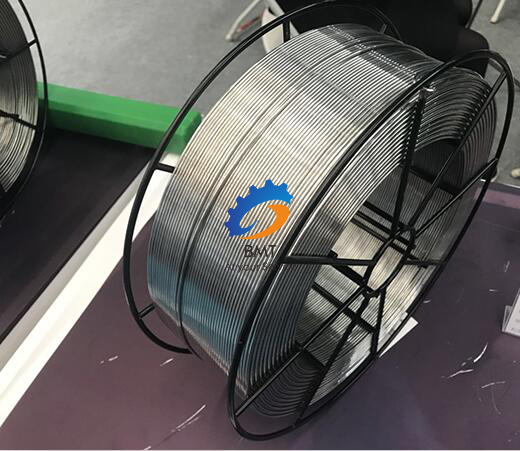

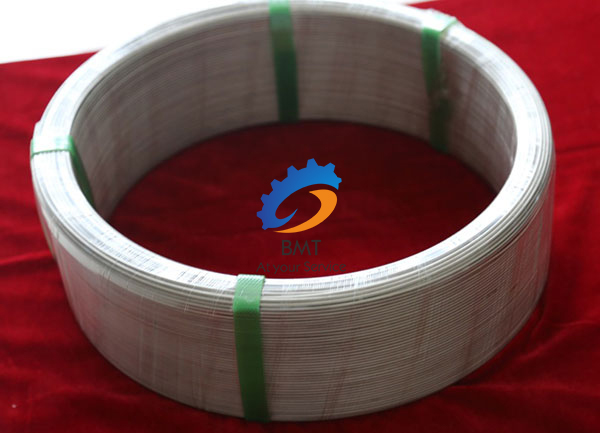

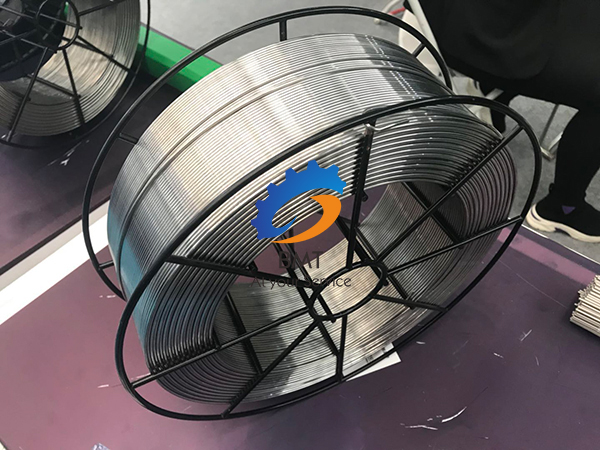

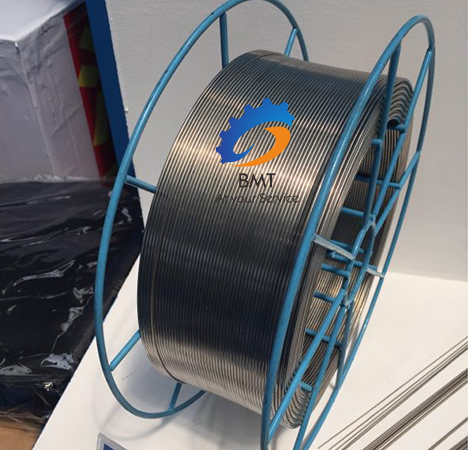

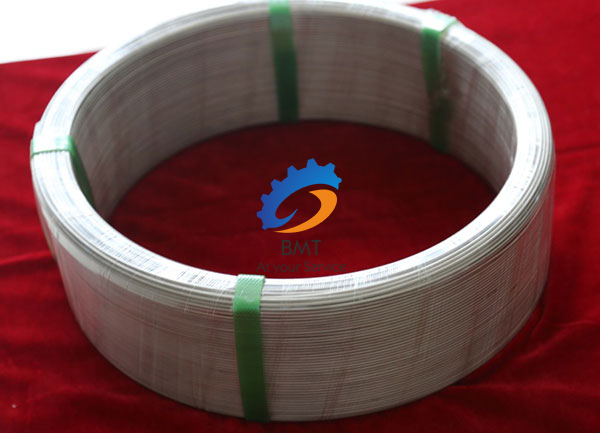

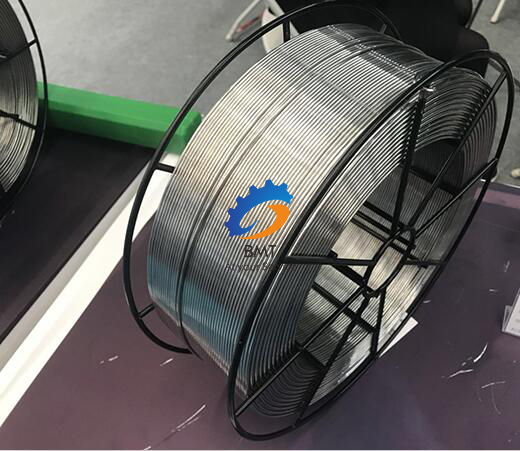

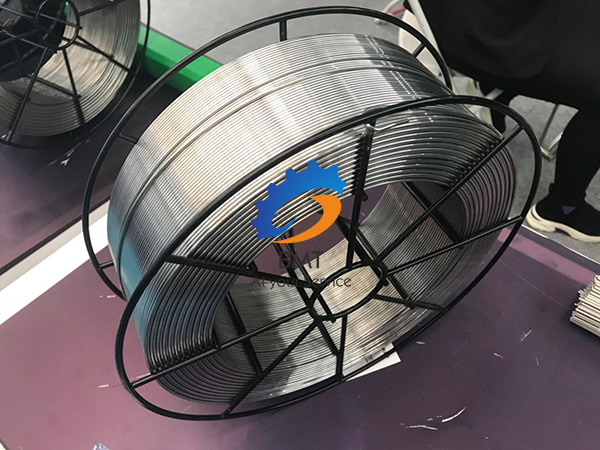

Ucingo lwe-titanium lwahlulwe lwaba: ucingo lwe-titanium, i-titanium alloy wire, i-titanium eyeglass wire, ucingo lwe-titanium oluthe tye, ucingo lwe-titanium olusulungekileyo, ucingo lwe-titanium welding, ucingo lwe-titanium olujingayo, ucingo lwe-titanium disk, ucingo olukhanyayo lwe-titanium, ucingo lwe-titanium yonyango, i-titanium nickel alloy wire. .

Iimpawu zeTitanium zocingo

A. Iimpawu zocingo lwe-Titanium: φ0.8-φ6.0mm

B. Iimpawu zocingo lwetitanium kwiiglasi: φ1.0-φ6.0mm ucingo olukhethekileyo lwetitanium

C. Iimpawu zocingo lwe-Titanium: φ0.2-φ8.0mm ngokuxhoma okukhethekileyo

Umgangatho:GB/T,GJB,AWS,ASTM,AMS,JIS

IBanga leTitanium Wire

GR1, GR2, GR3, GR5, GR7, GR9, GR11, GR12, GR16, njl.

Imimandla yokusetyenziswa kocingo lweTitanium

Ishishini lomkhosi, ezonyango, iimpahla zemidlalo, iiglasi, amacici, i-headwear, i-electroplating ejingayo, i-welding wire kunye namanye amashishini.

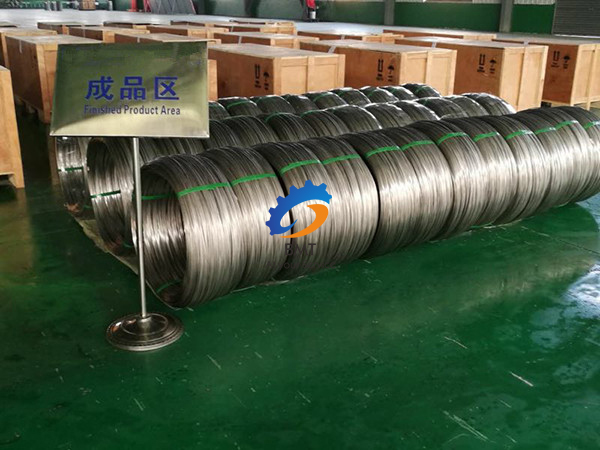

State of Titanium ngocingo

Imeko yokuphola (M)

Imeko yokusebenza eshushu (R)

Indawo yokusebenza ebandayo (Y)

(Annealing, Ultra-Generation Testing)

Umphezulu wocingo lweTitanium

Umphezulu wokuchola okanye ukhanyise umphezulu

Ucingo lwe-Titanium lwenza i-carbide ezinzileyo enobunzima obuphezulu kunye nekhabhoni. Ukukhula komaleko we-carbonized phakathi kwe-titanium kunye nekhabhoni kumiselwa yisantya sokusasazwa kwe-titanium kumaleko we-carbonized.

I-solubility yekhabhoni kwi-titanium incinci, ifikelela kwi-0.3% kwi-850X: kwaye iyancipha ukuya malunga ne-0.1% kwi-600C B Ngenxa yokunyibilika okuphantsi kwekhabhoni kwi-titanium, ukuqina komphezulu kufezekiswa kuphela nge-titanium carbide layer kunye ne-akimbo yayo. umaleko ongezantsi. I-Carburizing kufuneka yenziwe phantsi kwemeko yokususwa kwe-oksijini, ngenxa yokuba ukuqina komphezulu womgangatho womgubo oqhelekileyo usetyenziselwa intsimbi ye-carburizing ngokubhekiselele kumphezulu we-carbon monoxide okanye i-carbon monoxide equlethe i-carbon monoxide ukuya kwi-2700MPa kunye ne-8500MPa, kunye nomnatha. Kulula ukuyixobula.

Ukwakheka kweMichiza yeMathiriyeli ekhoyo

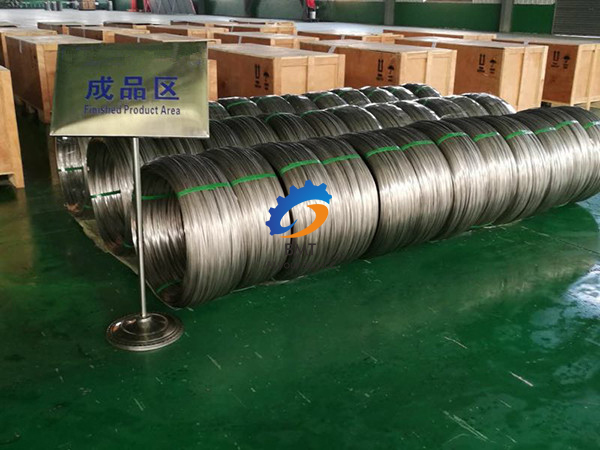

Imveliso (Ubuninzi kunye neMini encinci yoMyalelo):Unlimited, ngokomyalelo.

Ixesha lokukhokhela:Ixesha lokukhokela ngokubanzi ziintsuku ezingama-30. Nangona kunjalo, kuxhomekeke kwisixa somyalelo ngokufanelekileyo.

Ezothutho:Indlela jikelele yothutho luLwandle, ngoMoya, nge-Express, ngoLoliwe, oya kunyulwa ngabathengi.

Ukupakisha:

- Umbhobho uphela ukuba ukhuselwe ngeplastiki okanye i-caps cardboard caps.

- Zonke izifakelo kufuneka zipakishwe ukukhusela iziphelo kunye nokujongana.

- Zonke ezinye iimpahla ziya kupakishwa ngeephedi zogwebu kunye nokupakishwa kweplastiki ehambelanayo kunye neekesi zeplywood.

- Nawuphi na umthi osetyenziselwa ukupakisha kufuneka ulungele ukuthintela ukungcoliseka ngokudibana nezixhobo zokuphatha.

.jpg)

Ngokwahlukileyo, phantsi kwemeko ye-deoxygenation okanye i-decarburization, umgca omncinci we-titanium carbide unokuqulunqwa xa i-carburized in charcoal. Ubunzima bolu luhlu yi-32OUOMpa, ehambelana nobunzima be-titanium carbide. Ubunzulu bomaleko we-carburizing ngokubanzi bukhulu kunobo bomaleko we-nitriding xa i-nitriding isetyenziswa phantsi kweemeko ezifanayo. Ngaphantsi kwemeko yokutyetyiswa kwe-oksijeni, umphumo wokufunxa i-oksijini kubunzulu obunzima kufuneka uqwalaselwe. Kuphela phantsi kwemeko yobunzima obuncinci kakhulu apho amandla aneleyo ancamathelayo anokwakheka ngokufaka i-carburizing powder kwi-vacuum okanye kwi-argon-methane emoyeni. Ngokwahlukileyo koko, ukusetyenziswa kwe-agent ye-gas carburizing inokwenza umaleko oqinileyo we-titanium carbide oqinileyo ngokukodwa. Kwangaxeshanye, ukuqina ukusasazeka kwakheka kwiqondo lobushushu phakathi 950T: yaye 10201:. Ngokunyuka kobunzima bomaleko, umaleko we-TiC uba brittle kwaye uthande ukugqabhuka. Ukuze ugweme ukungena kwi-carbon inclusions kwi-TiC layer ngenxa yokuchithwa kweReane, i-gas carburizing kufuneka iqhutywe kwi-gas engasebenziyo kunye ne-additive dose emiselweyo malunga ne-2% yeReane. Ukuqina komphezulu osezantsi kufumaneka xa imethane ifakwe i-carburized nge-propane additives. Xa i-bonding force ifikelela kwi-OKPA kunye ne-gas carburized propane isetyenzisiweyo, nangona umlinganiselo obunzima bomaleko obunzima bubhityile kakhulu, unokumelana nokunxiba. I-Hydrogen ifunxwa yi-arhente ye-carburizing yegesi, kodwa kufuneka isuswe kwakhona ngexesha lokufunxa i-vacuum annealing.