I-Titanium Machining Ubunzima

I-thermal conductivity ye-titanium alloy incinci, ngoko ke ubushushu bokusika buphezulu kakhulu xa kusetyenzwa i-titanium alloy. Ngaphantsi kweemeko ezifanayo, ukushisa okusikiweyo kokucutshungulwa kwe-TC4 [i] kungaphezulu kokuphindwe kabini kweNombolo ye-45 yensimbi, kwaye ukushisa okwenziwa ngexesha lokucubungula kunzima ukudlula kwi-workpiece. Khupha; ubushushu obuthile be-titanium alloy buncinci, kwaye ukushisa kwendawo kuphakama ngokukhawuleza ngexesha lokucubungula. Ngoko ke, ukushisa kwesixhobo kuphezulu kakhulu, isicatshulwa sesixhobo sigugile ngokukhawuleza, kwaye ubomi benkonzo buyancipha.

Imodyuli esezantsi elastiki ye-titanium alloy[ii] yenza ukuba umphezulu owenziwe ngoomatshini uthambekele kwi-springback, ngakumbi ukwenziwa kweendawo ezinodonga olucekethekileyo kunzulu kakhulu, okulula ukubangela ukungqubana okuqinileyo phakathi kweflanki kunye nomphezulu owenziwe ngoomatshini, ngaloo ndlela unxibe isixhobo kunye ukutshiza. incakuba.

I-Titanium alloy inomsebenzi oqinileyo weekhemikhali, kwaye kulula ukusebenzisana neoksijini, i-hydrogen kunye ne-nitrogen kwiqondo lokushisa eliphezulu, okwandisa amandla ayo kunye nokunciphisa iplastiki yayo. Umaleko otyebileyo weoksijini owenziwe ngexesha lokufudumeza kunye nokubunjwa kwenza kube nzima ukwenza oomatshini.

Imigaqo yoMatshini yemathiriyeli ye-titanium alloy[1-3]

Kwinkqubo yomatshini, izixhobo ezikhethiweyo zesixhobo, iimeko zokusika kunye nexesha lokusika ziya kuchaphazela ukusebenza kakuhle kunye noqoqosho lwe-titanium alloy cutting.

1. Khetha isixhobo esifanelekileyo

Ngokweepropati, iindlela zokucubungula kunye nokucubungula iimeko zobugcisa bezinto ze-titanium alloy, izixhobo zesixhobo kufuneka zikhethwe ngokufanelekileyo. Isixhobo sesixhobo kufuneka sikhethwe sisetyenziswa ngokuqhelekileyo, ixabiso eliphantsi, ukuxhathisa okulungileyo, ubunzima obuphezulu be-thermal, kunye nokuqina okwaneleyo.

2. Ukuphucula iimeko zokusika

Ukuqina komatshini wokulungisa isixhobo kubhetele. Ukucocwa kwenxalenye nganye yesixhobo somatshini kufuneka kulungiswe kakuhle, kwaye i-radial runout ye-spindle kufuneka ibe yincinci. Umsebenzi wokugoba we-fixture kufuneka uqine kwaye uqine ngokwaneleyo. Inxalenye yokusika isixhobo kufuneka ibe mfutshane kangangoko kunokwenzeka, kwaye ubukhulu becala lokusika kufuneka bunyuswe kangangoko kunokwenzeka xa ukunyamezela kwe-chip kwanele ukuphucula amandla kunye nokuqina kwesixhobo.

3. Ukuphathwa kokushisa okufanelekileyo kwezinto ezicwangcisiweyo

Iipropati kunye nesakhiwo se-metallographic yezinto ze-titanium alloy zitshintshwa ngonyango lobushushu [iii], ukwenzela ukuba kuphuculwe ukucwangciswa kwezinto.

4. Khetha inani elifanelekileyo lokusika

Isantya sokusika kufuneka sibe phantsi. Ngenxa yokuba isantya sokusika sinempembelelo enkulu kwiqondo lokushisa lomgca wokusika, ukuphakama kwesantya sokusika, ukunyuka okubukhali kwiqondo lokushisa lomgca wokusika, kunye nobushushu bomphetho wokusika buchaphazela ngqo ubomi besixhobo, ngoko ke. kuyimfuneko ukukhetha isantya esifanelekileyo sokusika.

Thumela umyalezo wakho kuthi:

-

Aluminiyam CNC Machining Parts

-

I-Aluminiyam yePhepha leMetal Fabrication

-

Axis High Precision CNC Machining Parts

-

Izahlulo zoomatshini be-CNC base-Itali

-

CNC Machining Aluminiyam iinxalenye

-

Auto Parts Machining

-

I-Titanium Alloy Forgings

-

I-Titanium kunye ne-Titanium Alloy Fittings

-

I-Titanium kunye ne-Titanium Alloy Forgings

-

Iingcingo zeTitanium kunye neTitanium Alloy

-

Iibha zeTitanium

-

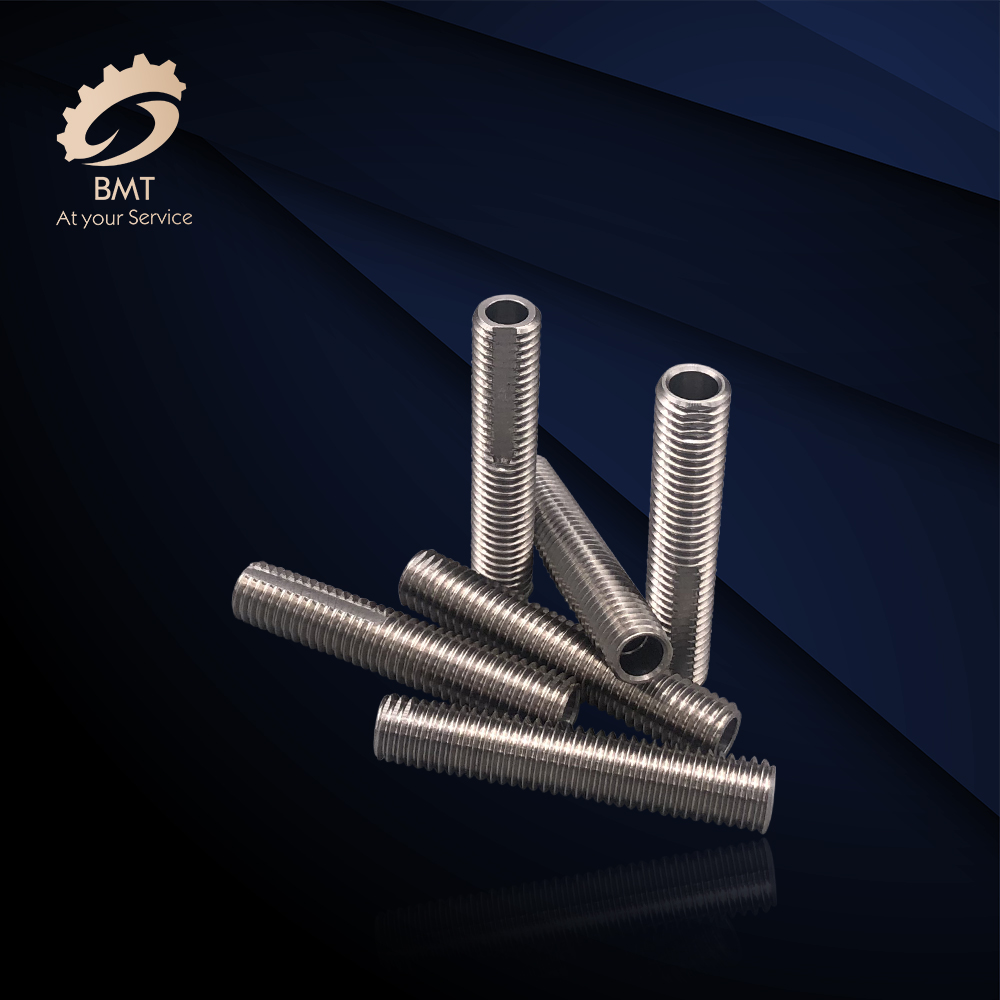

Imibhobho yeTitanium engenamthungo/iiThubhu

-

I-Titanium Welded imibhobho / iiThubhu