I-Titanium kunye ne-Titanium Alloy Forgings

I-Titanium kunye ne-titanium alloys zineenzuzo zokuxinana okuphantsi, amandla athile aphezulu kunye nokumelana okuhle kokubola, kwaye zisetyenziswa ngokubanzi kwiinkalo ezahlukeneyo.

I-Titanium forging yindlela yokwenza esebenza ngamandla angaphandle kwi-titanium metal blanks (Ngaphandle kweepleyiti) ukuvelisa ukuguqulwa kweplastiki, ukutshintsha ubungakanani, ukumila, kunye nokuphucula ukusebenza. Isetyenziselwa ukwenza amalungu oomatshini, izixhobo zokusebenza, izixhobo okanye iindawo ezingenanto. Ukongeza, ngokwepateni yentshukumo yesilayidi kunye neepateni zentshukumo ezithe nkqo nezithe tyaba zesilayidi (Ukwenza iindawo ezibhityileyo, ukuthambisa kunye nokupholisa, kunye nokwenziwa kweendawo zokuvelisa ngesantya esiphezulu), ezinye iindlela zokuhamba zinokunyuswa ngo. usebenzisa isixhobo sembuyekezo.

Ezi ndlela zingasentla zahlukile, kwaye amandla okubumba afunekayo, inkqubo, izinga lokusetyenziswa kwezinto, imveliso, ukunyamezela komlinganiselo, kunye neendlela zokuthambisa kunye nokupholisa nazo zahlukile. Ezi zinto zizinto ezichaphazela umgangatho wokuzenzekelayo.

I-Forging yinkqubo yokusebenzisa i-plastiki yesinyithi ukufumana inkqubo yokwenza iplastiki enemilo ethile kunye nezakhiwo zesakhiwo esingenanto phantsi kwempembelelo okanye uxinzelelo lwesixhobo. Ukuphakama kokuveliswa kwemveliso kukuba ayinakufumana kuphela imilo yamacandelo omatshini, kodwa iphinde iphucule isakhiwo sangaphakathi sezinto eziphathekayo kunye nokuphucula iipropati zemishini yamacandelo omatshini.

1. Ukuzenzela mahala

Ukubunjwa simahla ngokuqhelekileyo kwenziwa phakathi kweeflethi ezimbini ezifayo okanye ukungunda ngaphandle komngxuma. Izixhobo ezisetyenziselwa ukukhwabanisa simahla zilula ngokubunjwa, ziguquguqukayo, zifutshane kumjikelo wokuvelisa kunye neendleko eziphantsi. Nangona kunjalo, ukuqina kwabasebenzi kuphezulu, umsebenzi unzima, imveliso iphantsi, umgangatho we-forgings awuphezulu, kwaye isibonelelo somatshini sikhulu. Ngoko ke, kulungele ukusetyenziswa kuphela xa kungekho mfuneko ezikhethekileyo ekusebenzeni kwamacandelo kunye nenani leenqununu lincinci.

2. Vula iDie Forging (Die Forging with Burrs)

I-blank is deformed phakathi kweemodyuli ezimbini ezinemingxuma ekroliweyo, i-forging ivalwe ngaphakathi kumngxunya, kwaye isinyithi esingaphezulu siphuma kumsantsa ophakathi kokufa okubini, senza i-burrs ejikeleze i-forging. Ngaphantsi kokuchasana kwesikhunta kunye ne-burrs ejikelezileyo, isinyithi sinyanzeliswa ukuba sinyanzeliswe kwimilo ye-mold cavity.

3. Ivaliwe iDie Forging (Die Forging without Burrs)

Ngexesha lenkqubo evaliweyo yokubumba, akukho zityholo ezinqamlezileyo ze-perpendicular ukuya kwicala lentshukumo yokufa zenziwe. Umngxuma wokuvala i-forging die unemisebenzi emibini: enye yeyokwenza indawo engenanto, kwaye enye yeyokukhokela.

4. Extrusion Die Forging

Ukusebenzisa indlela ye-extrusion ye-die forging, kukho iindidi ezimbini zokubumba, i-extrusion yangaphambili kunye ne-reverse extrusion. I-Extrusion die forging inokuvelisa iindawo ezahlukeneyo ezingenanto kunye neziqinileyo, kwaye inokufumana i-forgings ngokuchaneka okuphezulu kwejometri kunye nolwakhiwo lwangaphakathi oluxineneyo.

5. Multi-Directional Die Forging

Yenziwa kumatshini wokwenza umkhomba-ndlela wokufa. Ukongeza kwipunking ethe nkqo kunye nenaliti yeplagi, umatshini wokwenza umkhomba-ndlela wokufa uneendlela ezimbini ezithe tye. I-ejector yayo ingasetyenziselwa ukubetha. Uxinzelelo lwe-ejector luphezulu kunolo lokushicilela kwe-hydraulic eqhelekileyo. Ukuba mkhulu. Kwi-multi-directional die forging, isilayidi sisebenza ngokungafaniyo nangokudibeneyo kwisixhobo sokusebenza ukusuka kumkhombandlela othe nkqo nothe tye, kwaye enye okanye ngaphezulu iipuntshi zokugqobhoza zisetyenziselwa ukwenza ukuba isinyithi siphume siphume kumbindi womgodi ukufezekisa injongo yokuzalisa intsimbi. umgodi.

6. Ukwahlula-hlula

Ukuze wenze i-forging enkulu edibeneyo kuxinzelelo olukhoyo lwe-hydraulic, iindlela zokwenziwa kwecandelo lokufa ezifana ne-difay forging kunye ne-shim plate die forging zingasetyenziswa. Isici sendlela yokubumba i-partial die forging yi-processing piece piece by piece, ukucubungula inxalenye enye ngexesha, ngoko ke i-tonnage yezixhobo ezifunekayo ingaba yincinci kakhulu. Ngokuqhelekileyo, le ndlela inokusetyenziselwa ukusetyenzwa kwe-forgings enkulu kumatshini wokushicilela we-hydraulic ophakathi.

7. Isothermal Die Forging

Ngaphambi kokubumba, isikhunta sifudunyezwa kwiqondo lokushisa lokubumba elingenanto, kwaye iqondo lokushisa lokubumba kunye nokungenanto lihlala lifanayo kuyo yonke inkqubo yokubumba, ukwenzela ukuba inani elikhulu lokuguqulwa lifumaneke phantsi kwesenzo samandla amancinci okuguqula. . I-Isothermal die forging kunye ne-isothermal superplastic die forging zifana kakhulu, umahluko kukuba ngaphambi kokufa kwe-faging, i-blank idinga ukuba i-superplasticized [i] ukuyenza ibe neenkozo ezilinganayo [ii].

Inkqubo yokubumba i-Titanium alloy isetyenziswa ngokubanzi kwinqwelomoya kunye nokuveliswa kwe-aerospace (Inkqubo ye-Isothermal Die Forgingiye yasetyenziswa ekuveliseni iinxalenye ze-injini kunye neenxalenye zesakhiwo seenqwelomoya), kwaye iya ithandwa ngakumbi kumacandelo emizi-mveliso afana neemoto, amandla ombane, kunye neenqanawa.

Okwangoku, iindleko zokusetyenziswa kwezinto ze-titanium ziphezulu kakhulu, kwaye amasimi amaninzi asekuhlaleni awakaqapheli ngokupheleleyo umtsalane we-titanium alloys. Ngokuqhubela phambili okuqhubekayo kwesayensi, ukulungiswa kwe-titanium kunye ne-titanium alloy iteknoloji yemveliso iya kuba lula kwaye iindleko zokucubungula ziya kuba ngaphantsi naphantsi, kwaye i-charm ye-titanium kunye ne-titanium alloy imveliso iya kugxininiswa kuluhlu olubanzi lweenkalo.

Using extrusion indlela for die forging, kukho iindidi ezimbini forging, Phambili Extrusion kunye Extrusion Reverse. I-Extrusion Die Forging inokuvelisa iindawo ezahlukeneyo ezingenanto kunye neziqinileyo, kwaye inokufumana i-forgings ngokuchaneka okuphezulu kwejometri kunye nolwakhiwo lwangaphakathi oluxineneyo.

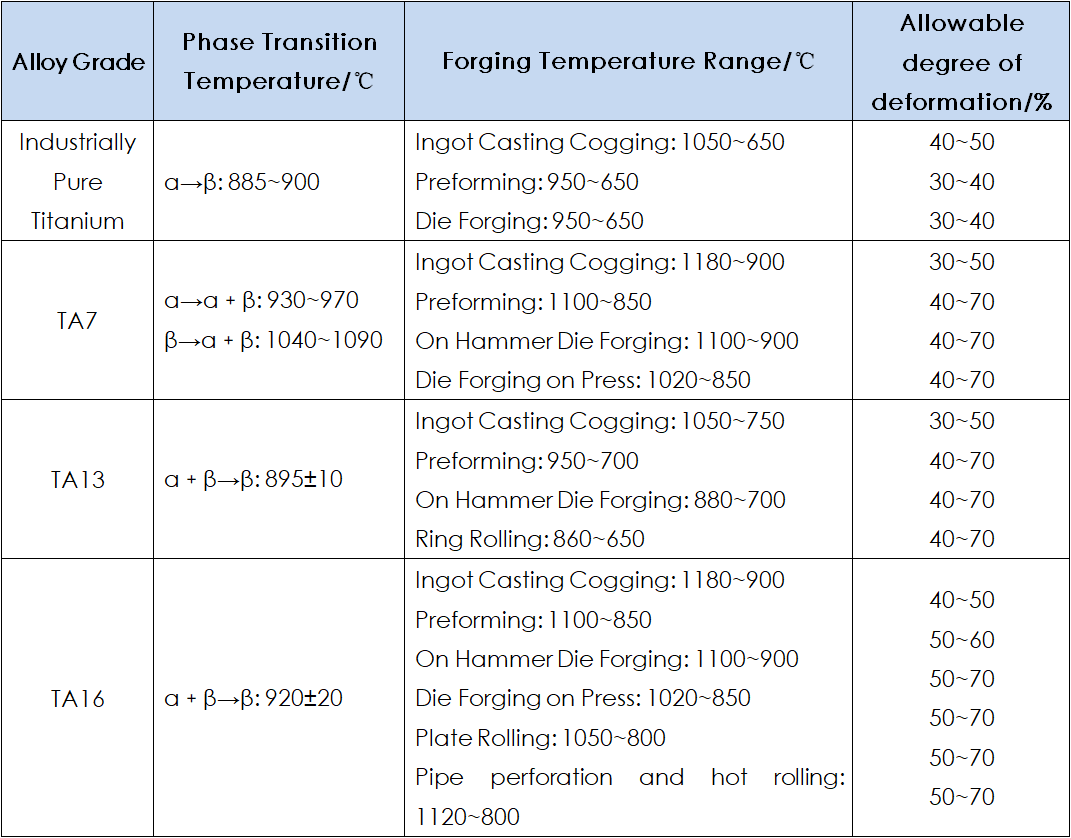

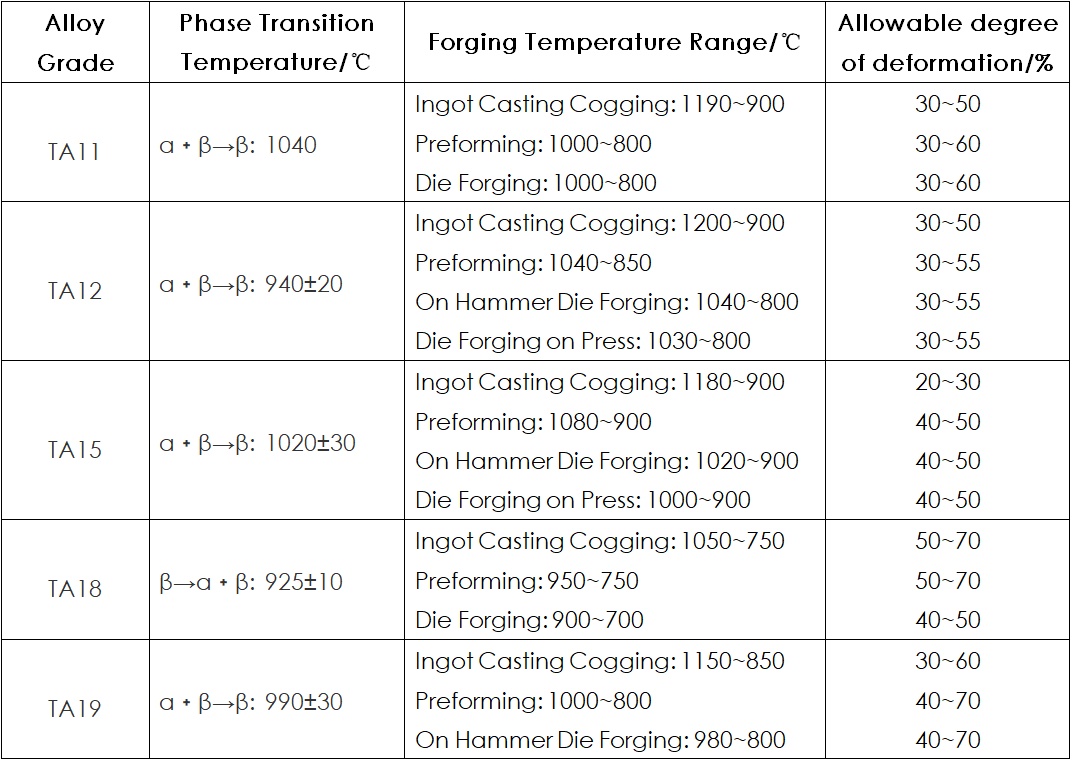

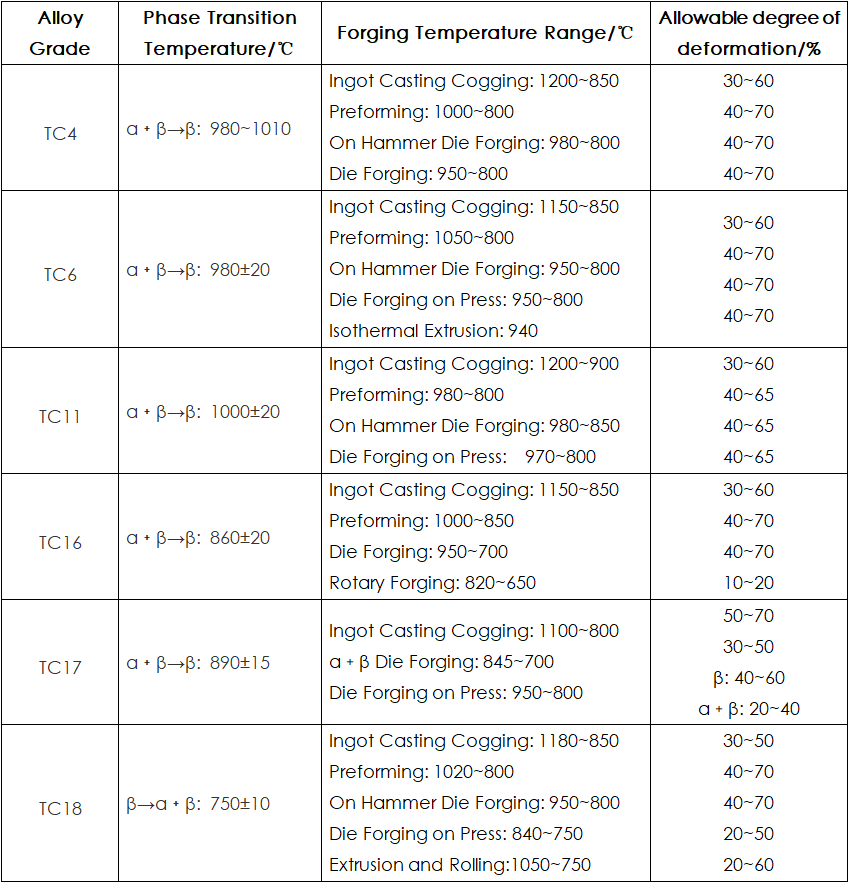

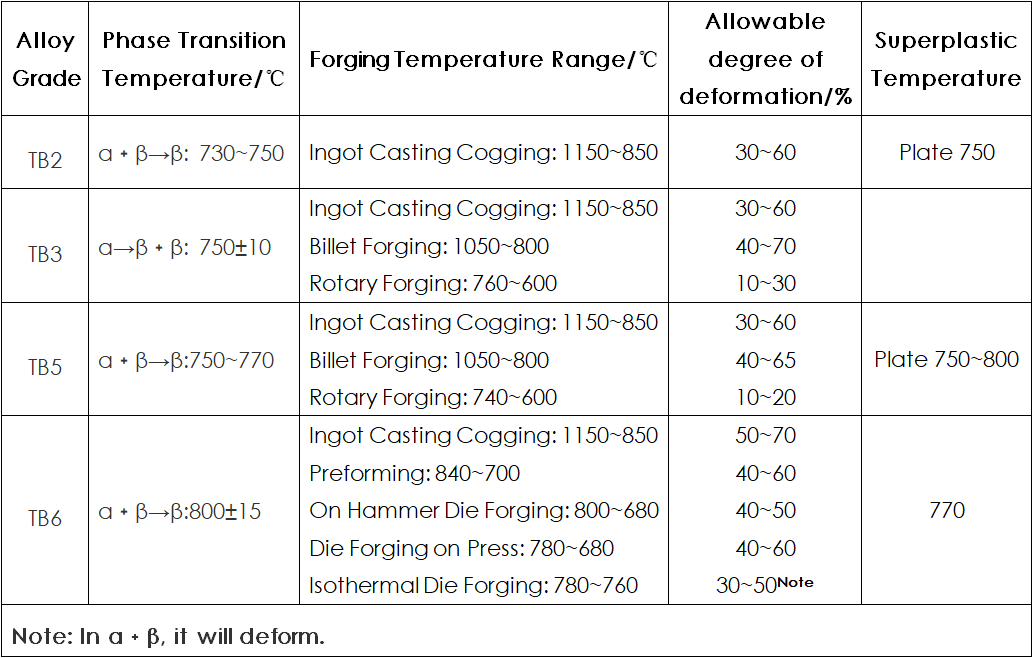

Ngokutsho kophando lwethiyori kunye namava okuveliswa kwefektri, idatha yokusebenza kwenkqubo yokubumba ye-α-uhlobo, i-alpha-uhlobo, i-α﹢β-uhlobo kunye ne-al-β-type titanium alloys ishwankathelwe kwiThebhile 1 kwiThebhile 4, ngokulandelanayo.

Ukusuka kwidatha ekwiTheyibhile 1 ukuya kwiThebhile 4, kunokubonwa ukuba ubushushu bebhilengi yee-ingots ezininzi ze-titanium alloy kuluhlu lwe-1150 ° C ukuya kwi-1200 ° C, kwaye iqondo lobushushu lokuqala le-titanium alloy ingots likuluhlu. of 1050°C ukuya 1100°C; Le mimandla yobushushu mibini ibekwe kwindawo yesigaba se-β, kwaye eyokuqala iphezulu kunobushushu besigaba sokutshintsha ngenxa yezizathu ezininzi.

Okokuqala, i-alloy inokwakheka okuphezulu kunye nokuchasana kwe-deformation ephantsi kwindawo yesigaba se-β. Ukuze uzame ixesha elide lokubumba, Kuyinzuzo ukuphucula imveliso; okwesibini, i-billet ye-ingot blooming inikezelwa ngokuyintloko njengento engenanto yokwenza. Emva kokuqulunqa ngeqondo elikhulu le-deformation, isakhiwo sinokuphuculwa ngaphandle kokuchaphazela ukusebenza kwe-forging. Ngoko ke, inkqubo enemveliso ephezulu ikhethiwe.

Ukususela kwidatha ekwiThebhile 1 ukuya kwiThebhile 4, kunokubonwa ukuba iqondo lokushisa lokuqala lokubumba kwi-press liphantsi kakhulu kuneqondo lokushisa lokuqala le-ingot billet, kodwa lingaphantsi kwe-α / β iqondo lokushisa. ngo 30℃~50℃. Uninzi lwe-titanium Ubushushu bokwenza i-die forging ye-alloy ikuluhlu lwe-930℃~970℃, oko kukuqinisekisa ukuguqulwa kwingingqi yesigaba se-α﹢β ukufumana i-microstructure efunekayo kunye neepropati zokubumba. Kuba ukubunjwa kwesando sokufa kufuna izithonga ezininzi kwaye ixesha lokusebenza lide, iqondo lobushushu lokufudumeza lokufa kwezixhobo zalo ezigqityiweyo linokongezwa ngokufanelekileyo nge-10 ℃ ~ 20 ℃ kunelo lokushicilela. Nangona kunjalo, ukuze kuqinisekiswe ubume kunye neepropathi zoomatshini be-titanium alloy egqityiweyo ukubunjwa, Ke ngoko, ubushushu bokugqibela bokubumba benkqubo yokubumba kufuneka ilawulwe kwingingqi ye-α﹢β yezigaba ezimbini.

Inokubonwa kwakhona kwidatha ekwiThebhile 1 ukuya kwiThebhile 4 ukuba iqondo lobushushu lokuqala lokubumba uninzi lwe-titanium alloy preforms liphezulu kancinane okanye likufutshane neqondo lobushushu besigaba. Iqondo lobushushu lokuqala le-α/β lenkqubo yenguqu efana ne-preforming lisezantsi kuneqondo lobushushu le-ingot blooming, kwaye liphezulu kunobushushu bokuqala bokubumba be-die forging. I-Deformation kule ndawo yokushisa ayikhathaleli kuphela imveliso, kodwa ilungiselela isakhiwo esilungileyo sokubumba.

Itheyibhile 1 Ukuqulunqa idatha yokusebenza kwenkqubo ye-α-uhlobo lwe-titanium

Itheyibhile 2 Ukuqulunqa idatha yokusebenza kwenkqubo ekufutshane ne-α-uhlobo lwe-titanium alloy

Uluhlu 3 Ukuqulunqa idatha yokusebenza kwenkqubo ye-α﹢β ingxubevange yetitanium

Itheyibhile 4 Ukuqulunqa idatha yokusebenza kwenkqubo ekufutshane ne-β-type titanium alloy

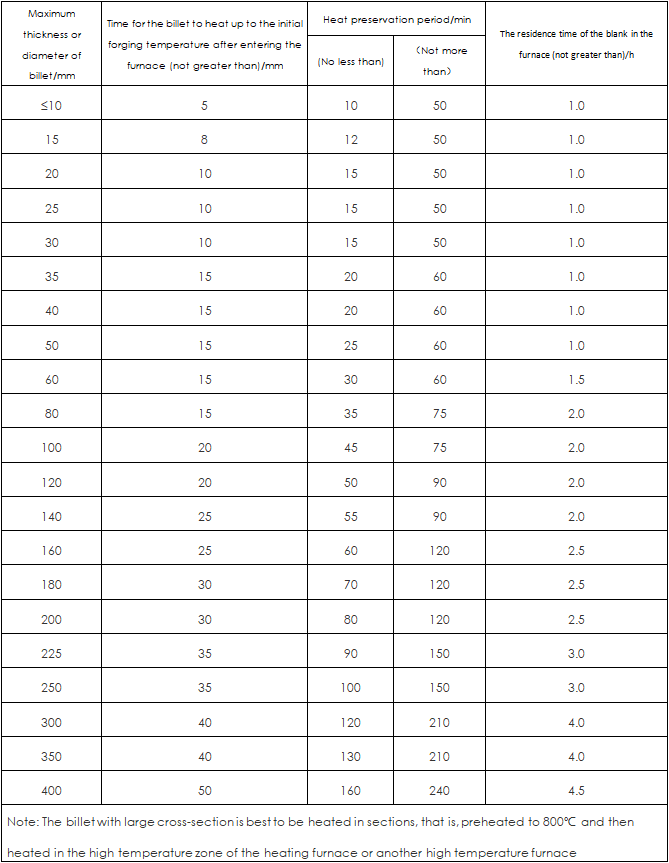

Itheyibhile 5 Ukufudumeza kunye nokubamba ixesha le-titanium alloy blanks

I-BMT ikhethekileyo ekuveliseni i-premium ye-titanium yokwenziwa kunye ne-titanium alloy forging enomthamo ogqwesileyo womatshini, ukuqina, ukunganyangeki komhlwa, uxinano oluphantsi kunye nokuqina okuphezulu. Ukuveliswa okusemgangathweni kwemveliso ye-titanium ye-BMT kunye nenkqubo yokufumanisa yoyise ukuntsonkotha kobuchwepheshe kunye nobunzima bomatshini bokwenziwa kwe-titanium.

Umgangatho ophezulu wemveliso ye-titanium echanekileyo isekelwe kuyilo lwenkqubo yobugcisa kunye nendlela eqhubekayo ngokuthe ngcembe. Ukubunjwa kwe-titanium ye-BMT kunokufakwa kuluhlu ukusuka kwisakhiwo esixhasayo samathambo amancinci ukuya kwisayizi enkulu ye-titanium yokwenziwa kweenqwelomoya.

I-BMT ye-titanium forgings isetyenziswa ngokubanzi kumashishini amaninzi, afana ne-aerospace, ubunjineli be-offshore, i-oyile kunye negesi, imidlalo, ukutya, i-automobile, njl.

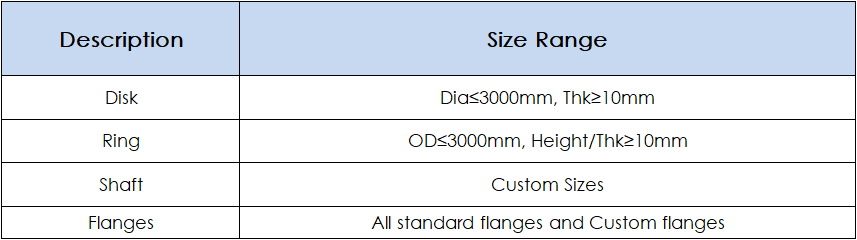

Uluhlu lobungakanani:

Ukwakheka kweMichiza yeMathiriyeli ekhoyo

Ukwakheka kweMichiza yeMathiriyeli ekhoyo

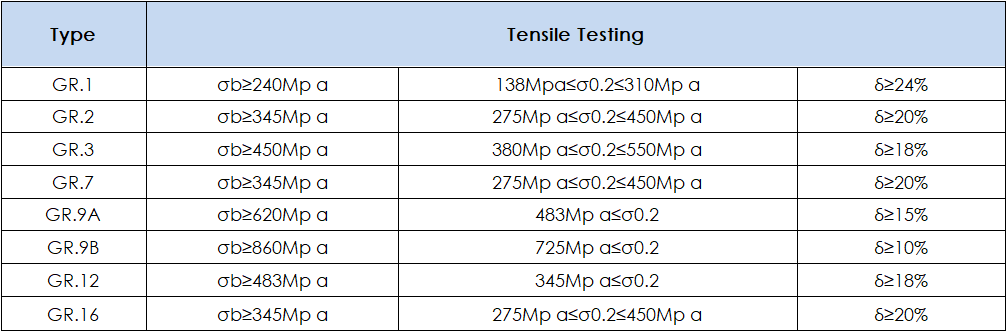

Uvavanyo lokuhlola:

- Uhlalutyo lokuBumba kweMichiza

- Uvavanyo lwePropati yoomatshini

- Uvavanyo lwe-Tensile

- Uvavanyo oluvuthayo

- Uvavanyo lokucaba

- Ukugoba uvavanyo

- Uvavanyo lweHydro-Static

- Uvavanyo lwePeneumatic (Uvavanyo loxinzelelo lomoya phantsi kwamanzi)

- Uvavanyo lwe-NDT

- Eddy-Yangoku Test

- Uvavanyo lwe-ultrasonic

- Uvavanyo lwe-LDP

- Uvavanyo lweFerroxyl

Imveliso (Ubuninzi kunye neMini encinci yoMyalelo):Unlimited, ngokomyalelo.

Ixesha lokukhokhela:Ixesha lokukhokela ngokubanzi ziintsuku ezingama-30. Nangona kunjalo, kuxhomekeke kwisixa somyalelo ngokufanelekileyo.

Ezothutho:Indlela jikelele yothutho luLwandle, ngoMoya, nge-Express, ngoLoliwe, oya kunyulwa ngabathengi.

Ukupakisha:

- Umbhobho uphela ukuba ukhuselwe ngeplastiki okanye i-caps cardboard caps.

- Zonke izifakelo kufuneka zipakishwe ukukhusela iziphelo kunye nokujongana.

- Zonke ezinye iimpahla ziya kupakishwa ngeephedi zogwebu kunye nokupakishwa kweplastiki ehambelanayo kunye neekesi zeplywood.

- Nawuphi na umthi osetyenziselwa ukupakisha kufuneka ulungele ukuthintela ukungcoliseka ngokudibana nezixhobo zokuphatha.