Imibuzo eyiyo yoCwangciso lweCNC

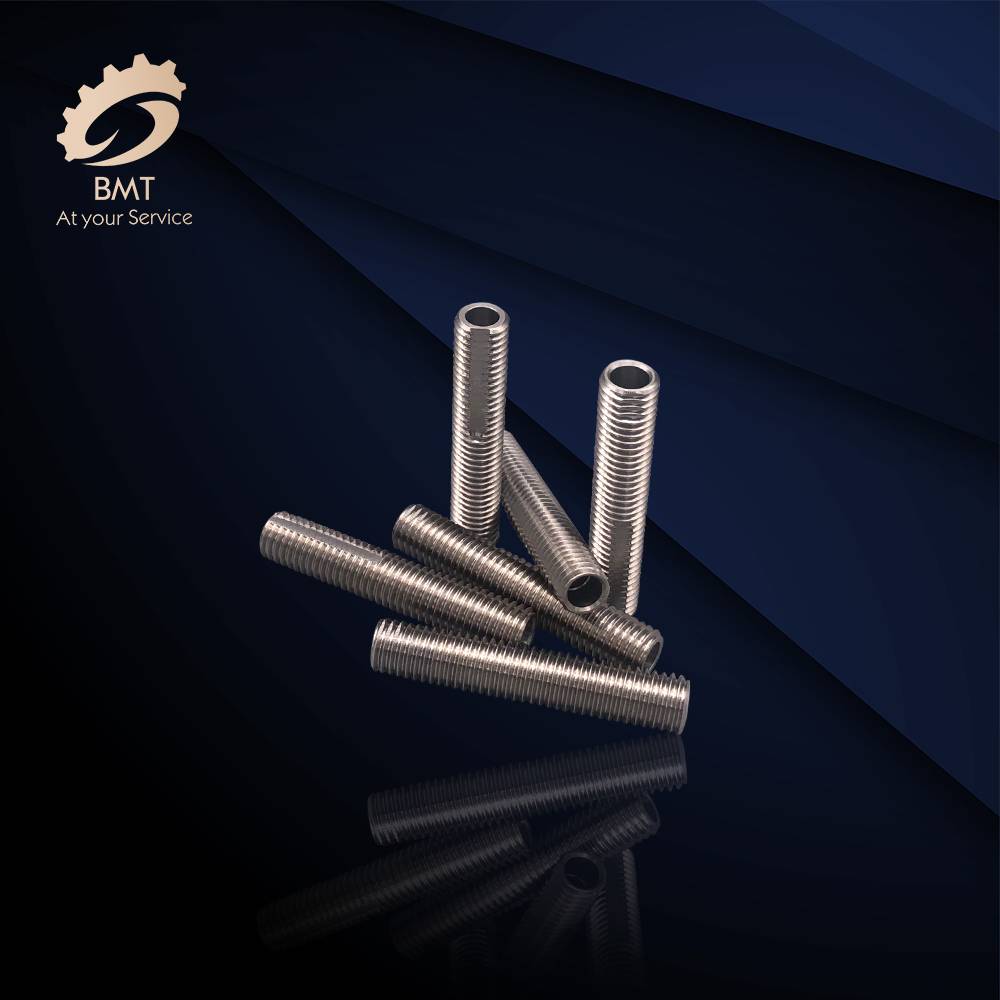

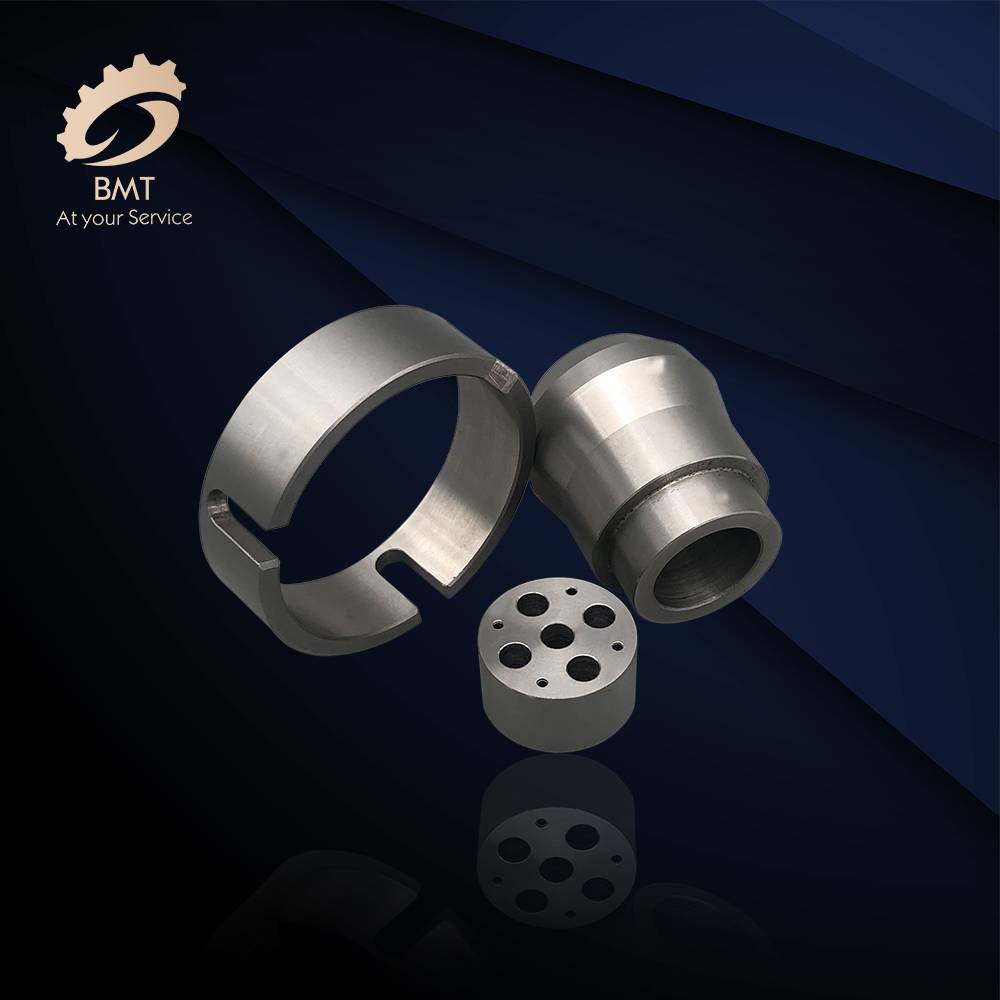

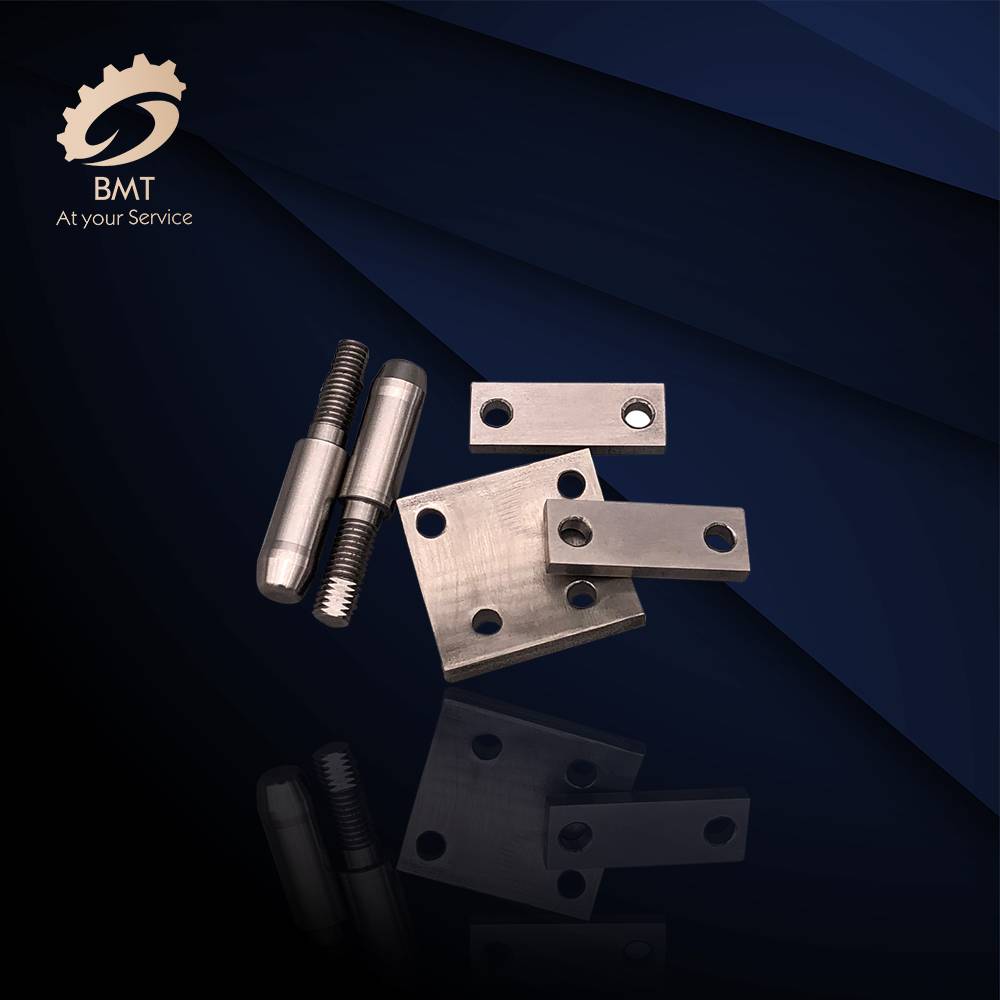

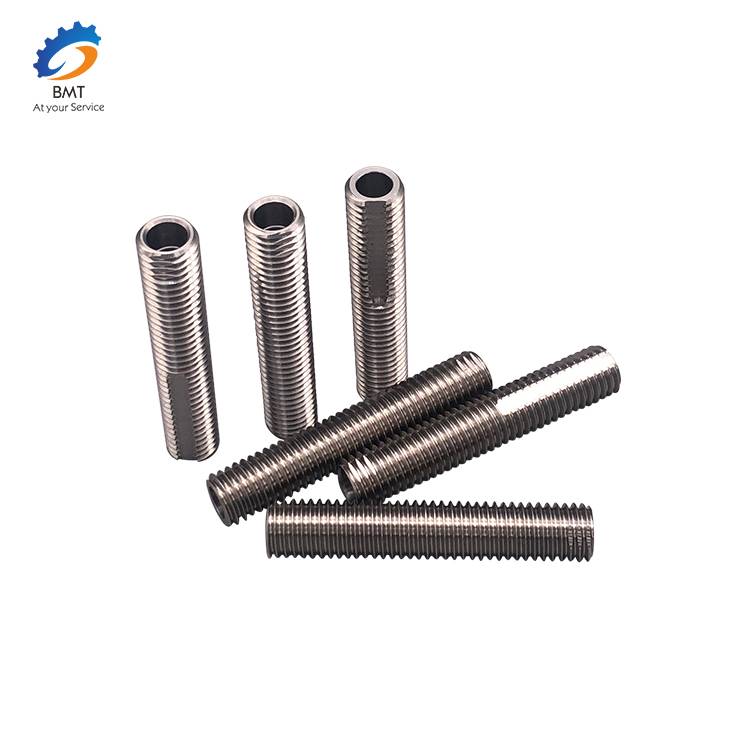

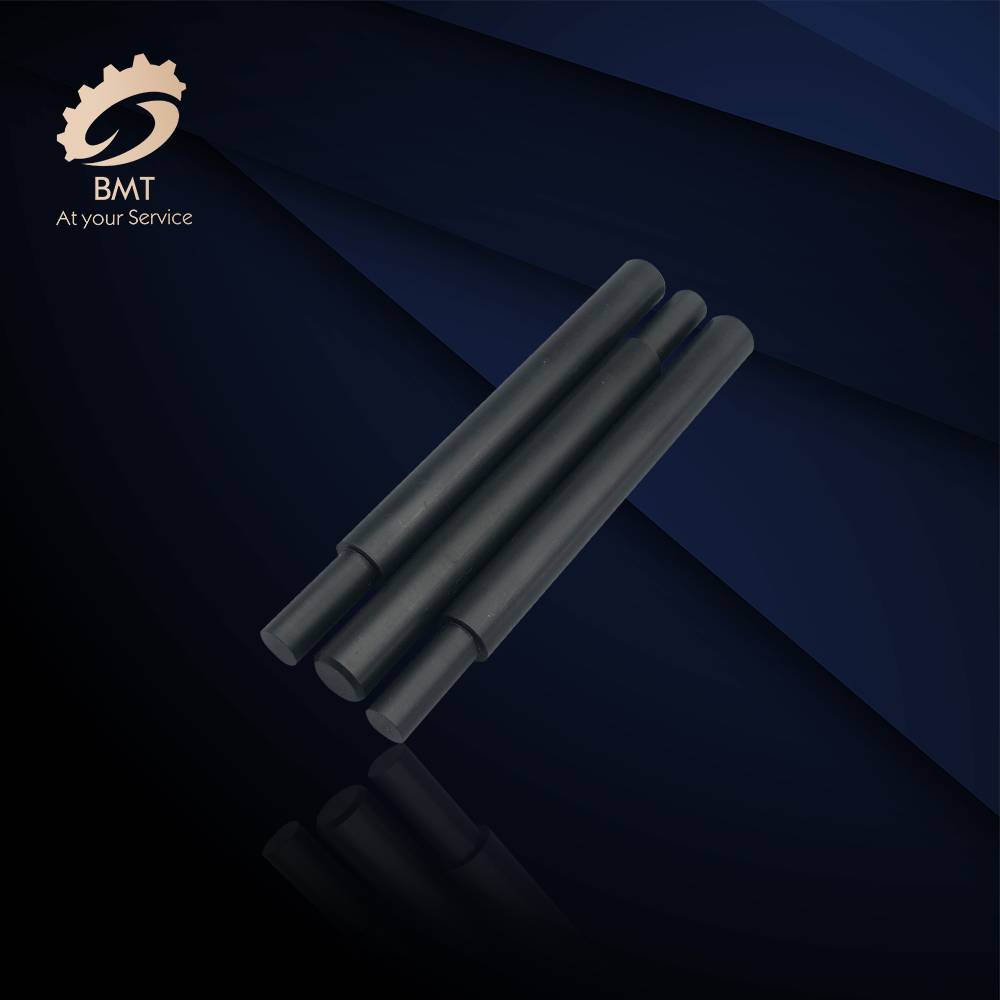

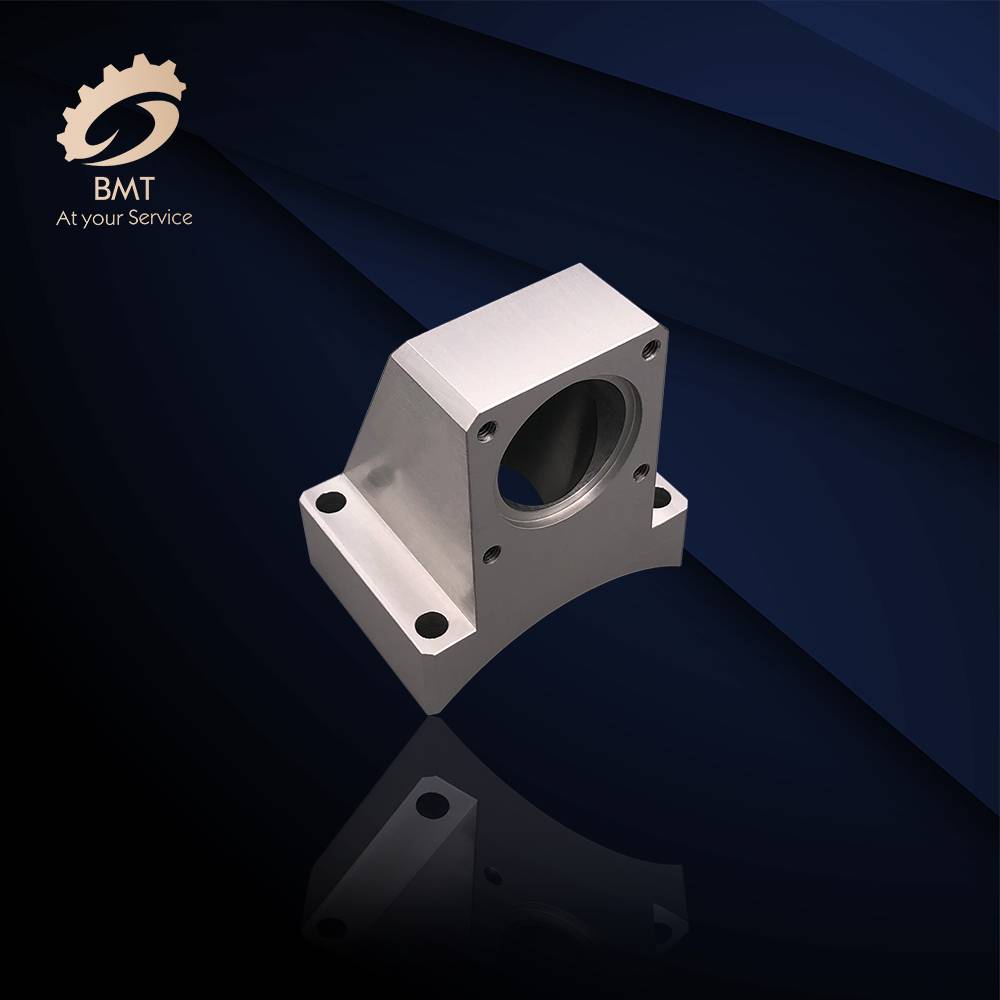

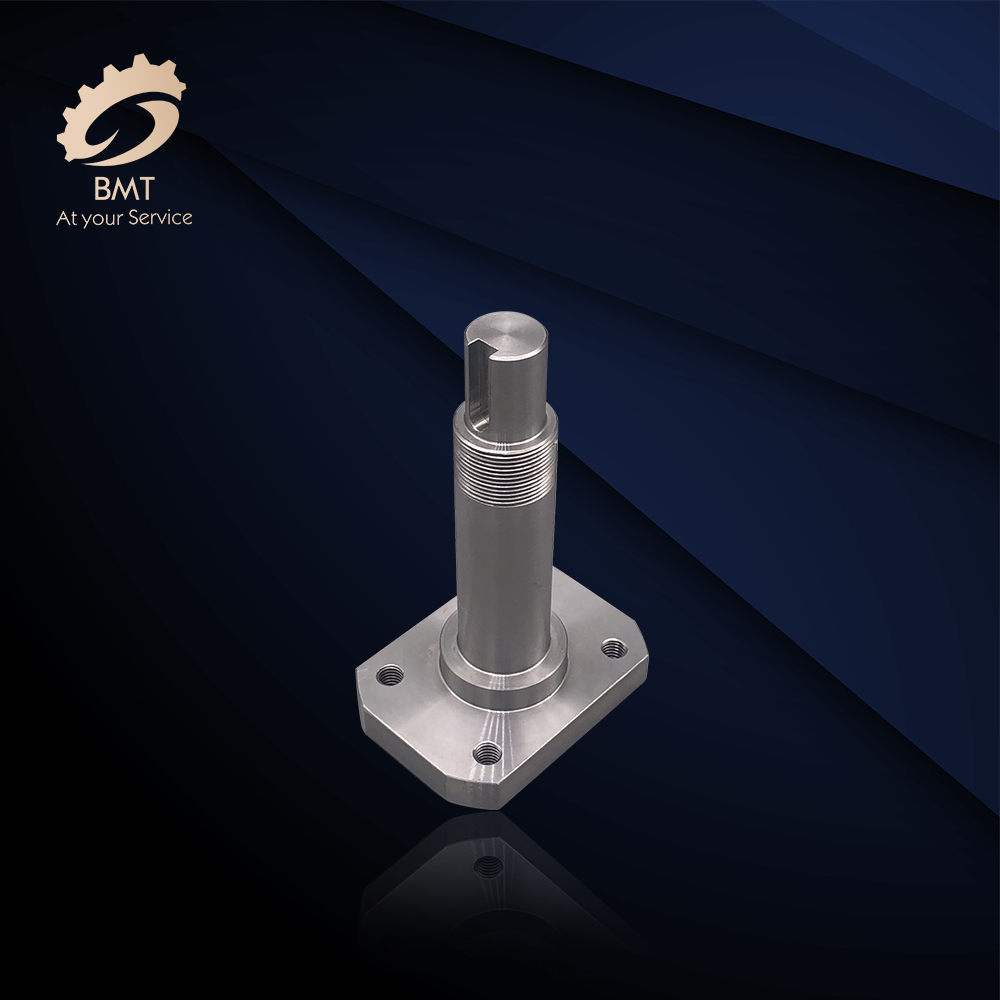

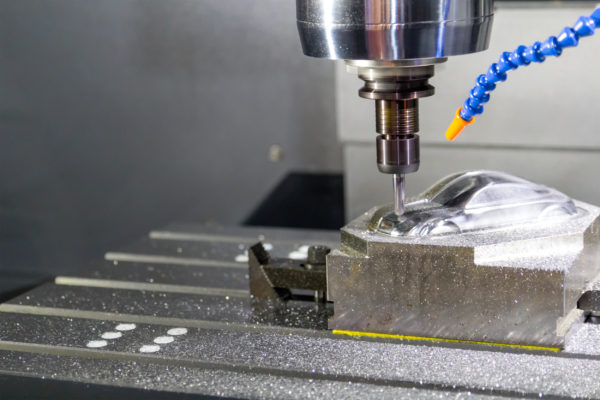

Ukuchaneka komatshini kunokuzisa nayiphi na inkqubo yokuvelisa kwinqanaba elilandelayo. Inokusebenza ngokumangalisayo ekusebenzeni kakuhle, ukunciphisa ixesha lokutshintsha, kunye nokunciphisa iindleko zemveliso. Ngubani owaziyo oku ngcono kunomnye wabavelisi abakhulu be-CNC yokuGuqulela kunye neMilling abaneminyaka eyi-15 yamava phantsi kwebhanti yayo? I-BMT ibonelele ngamacandelo achanekileyo akhethekileyo kumashishini ukusukela ngoko.

Uthintelo kunye nolawulo lokungcangcazela koomatshini:

Ukuphelisa okanye ukwenza buthathaka iimeko ezivelisa i-vibration yomatshini; Ukuphucula iimpawu eziguquguqukayo zenkqubo yenkqubo ukuphucula uzinzo lwenkqubo yenkqubo usebenzisa iintlobo ngeentlobo zezixhobo zokudambisa ukungcangcazela.

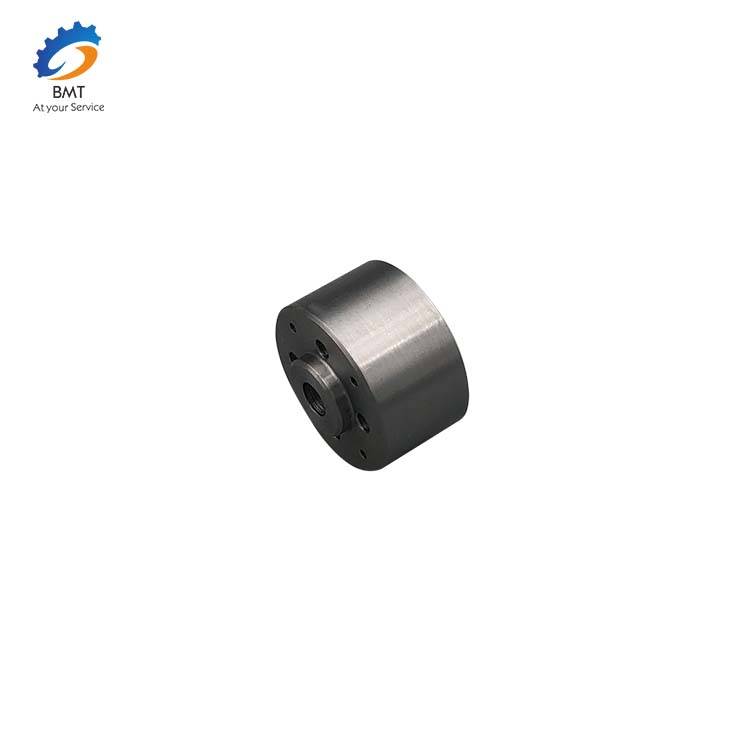

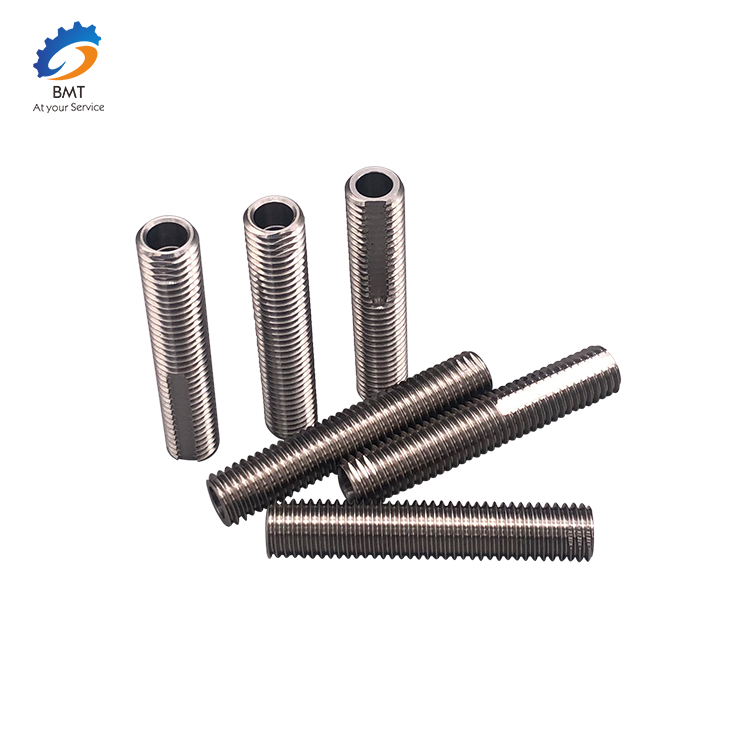

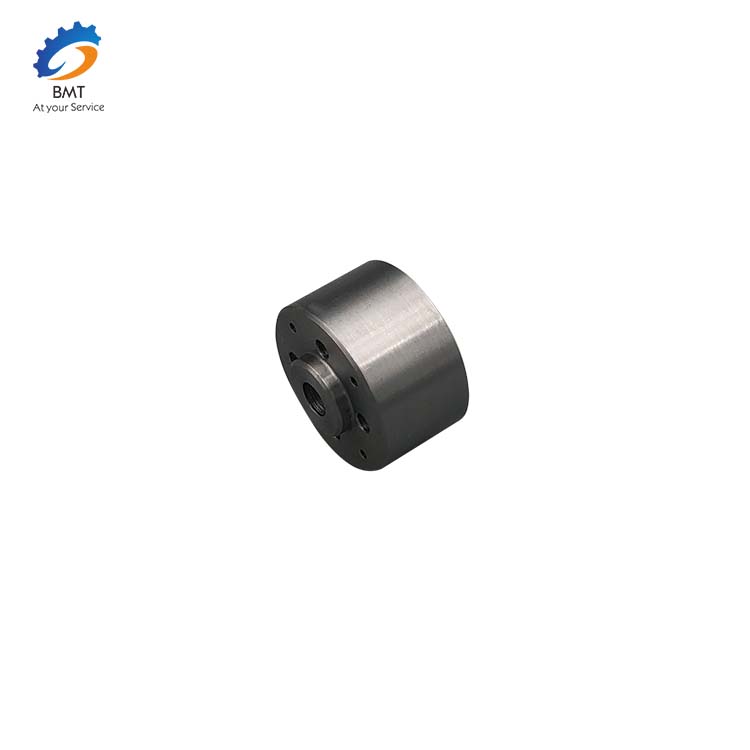

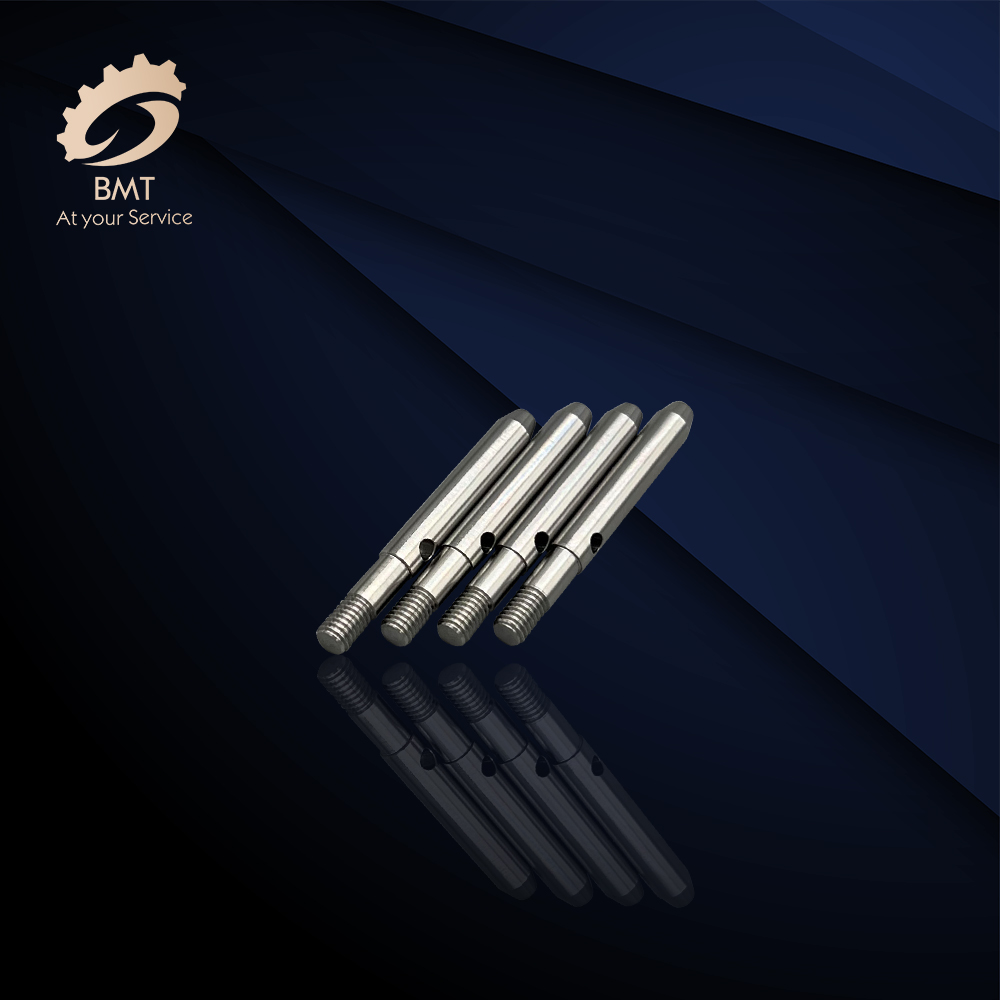

Ingcaciso yeMveliso

Kutheni ukhetha iiNdawo zoomatshini bethu be-CNC?

Umgaqo-siseko wokukhetha umlinganiselo orhabaxa? Umgaqo wokhetho lomgangatho olungileyo?

Umlinganiselo okrwada:

1. Umgaqo wokuqinisekisa iimfuno zesikhundla;

2. Umgaqo-nkqubo wokuqinisekisa ulwabiwo olufanelekileyo lwesibonelelo somatshini womhlaba womatshini;

3. Umgaqo-siseko we-workpiece clamping efanelekileyo;

4. Umgaqo wokuba i-coarse datum mayingaphinde isetyenziswe ngokubanzi

Ibenchmark elungileyo:

1. Umgaqo-siseko wokudibana kwedatha;

2. Umgaqo-siseko odityanisiweyo;

3. Umgaqo-siseko wokuthelekisa;

4. Umgaqo-siseko wokuzisebenzela;

5. Kulula ukubamba umgaqo.

Yeyiphi imigaqo yolandelelwano lwenkqubo?

a) Qala uqhubele phambili umgangatho wogcino-lwazi, emva koko uqhube neminye imiphezulu;

b) Kwisiqingatha seemeko, umphezulu ucutshungulwa kuqala, kwaye emva koko umngxuma uqhutywe;

c) Indawo ephambili icutshungulwa kuqala, kwaye indawo yesibini icutshungulwa kamva;

d) Lungiselela inkqubo yokurhabaxa kuqala, emva koko ugqibezele.

Indlela yokwahlula inqanaba lokucubungula? Ziziphi iingenelo zokwahlula izigaba zokusetyenzwa?

Inqanaba lokuqhubekekisa icandelo:

1) Isigaba somatshini orhabaxa

2) Isigaba sokugqiba

3) Ukugqiba isigaba

4) Ukuchaneka kwenqanaba lokugqiba

Inokuqinisekisa ixesha elaneleyo lokuphelisa i-deformation ye-thermal kunye noxinzelelo olushiyekileyo olubangelwa ukucwangciswa kakubi, ukwenzela ukuba kuphuculwe ukuchaneka komatshini olandelayo. Ukongeza, kwinqanaba lokucubungula elirhabaxa lifunyenwe iziphene ezingenanto akufuneki ukuba zicutshungulwe kwinqanaba elilandelayo lokucubungula, ukuphepha inkunkuma. Ukongezelela, ukusetyenziswa ngokufanelekileyo kwezixhobo, izixhobo zomatshini ezichanekileyo ezisezantsi zokuchaneka komatshini wokuchaneka kwezixhobo zokugqiba, ukuze kugcinwe umgangatho ochanekileyo wezixhobo zomatshini ezichanekileyo; Ulungiselelo olunengqiqo lwabasebenzi, abasebenzi be-high-tech abasebenza ngokuchaneka kwe-ultra-precision processing, ebaluleke kakhulu ekuqinisekiseni umgangatho weemveliso, ukuphucula umgangatho wobugcisa.