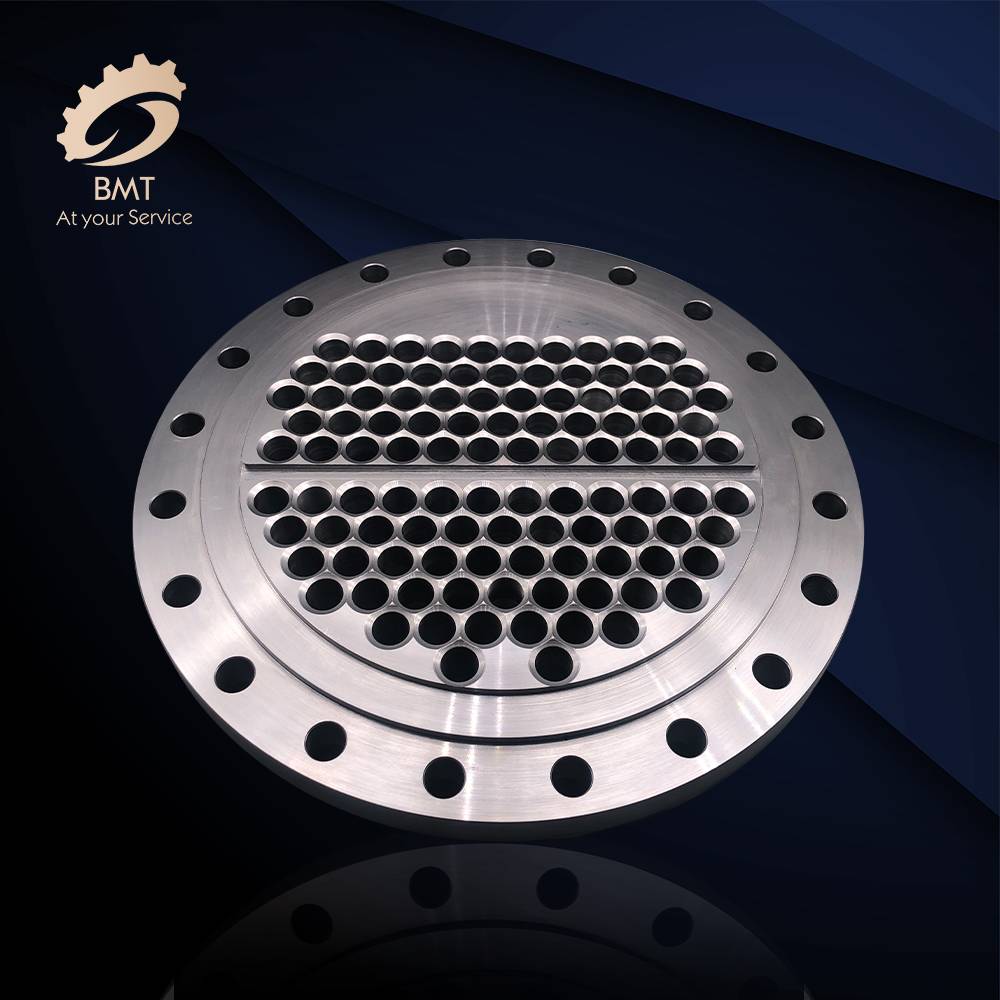

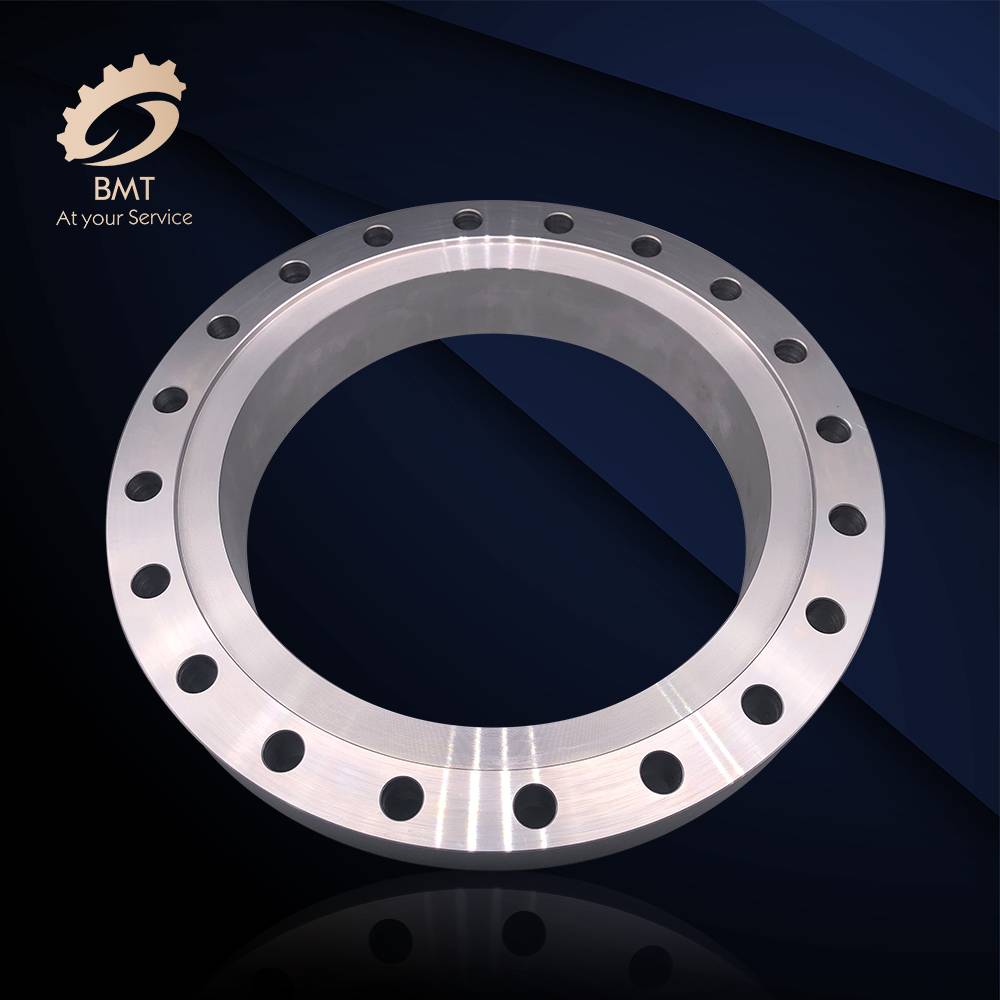

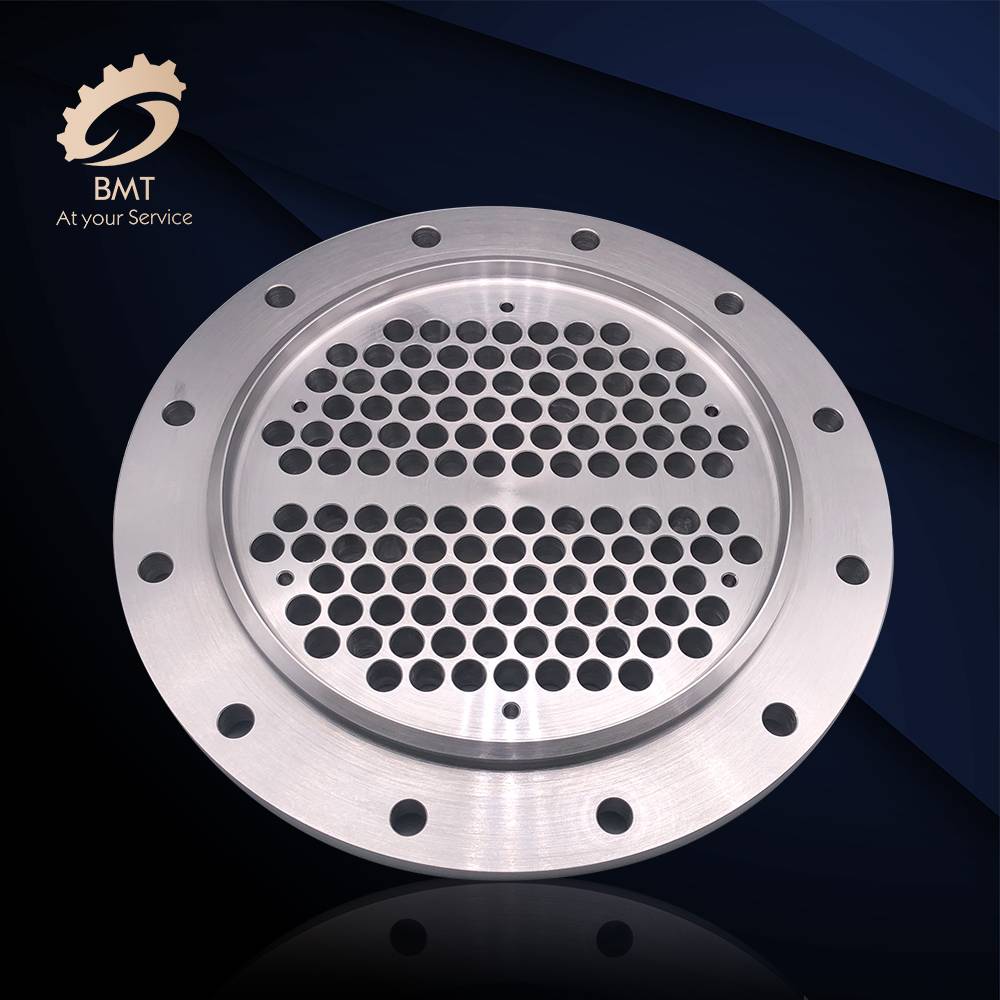

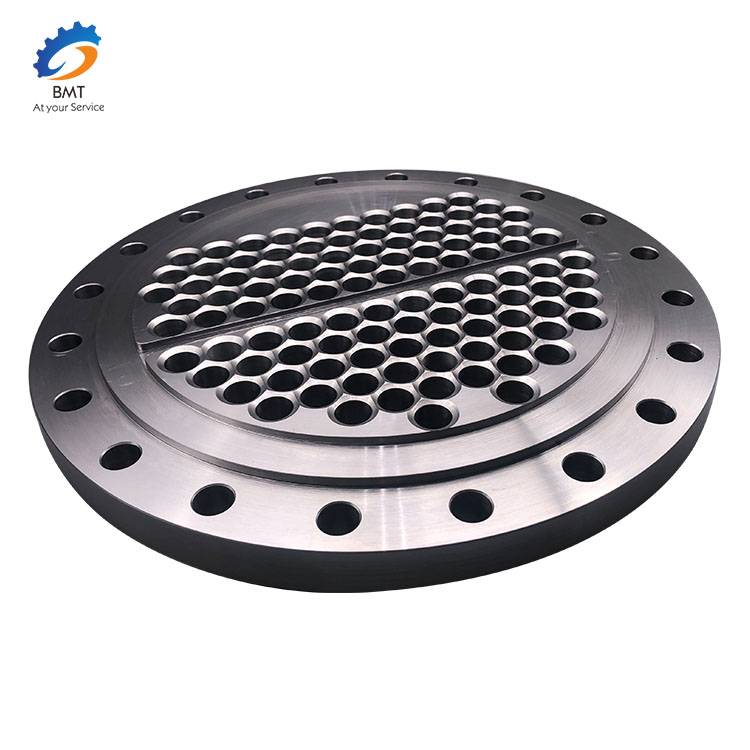

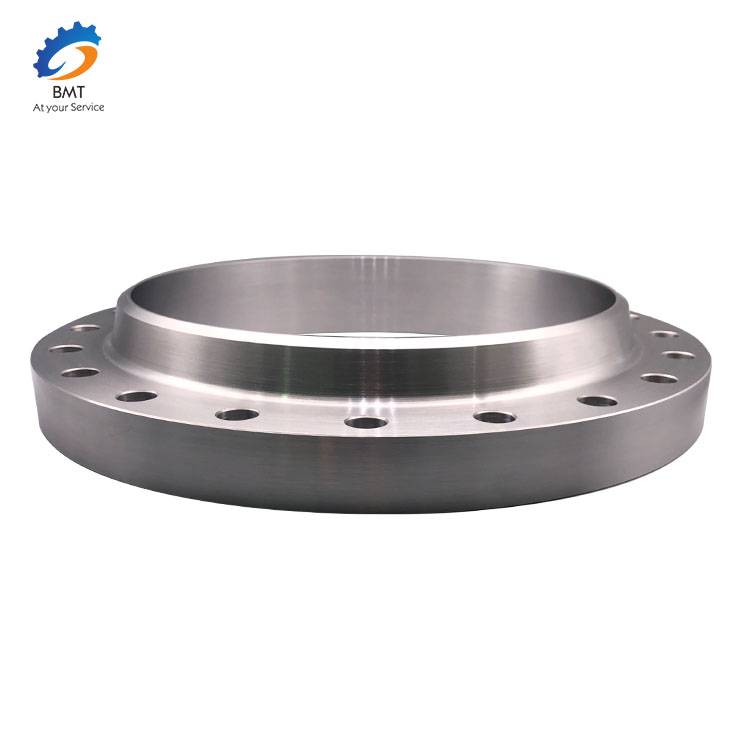

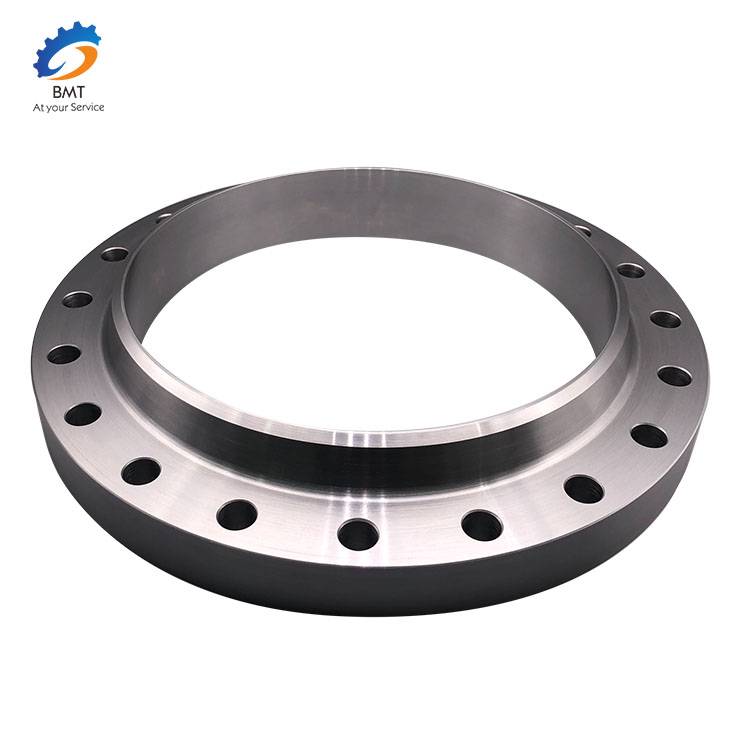

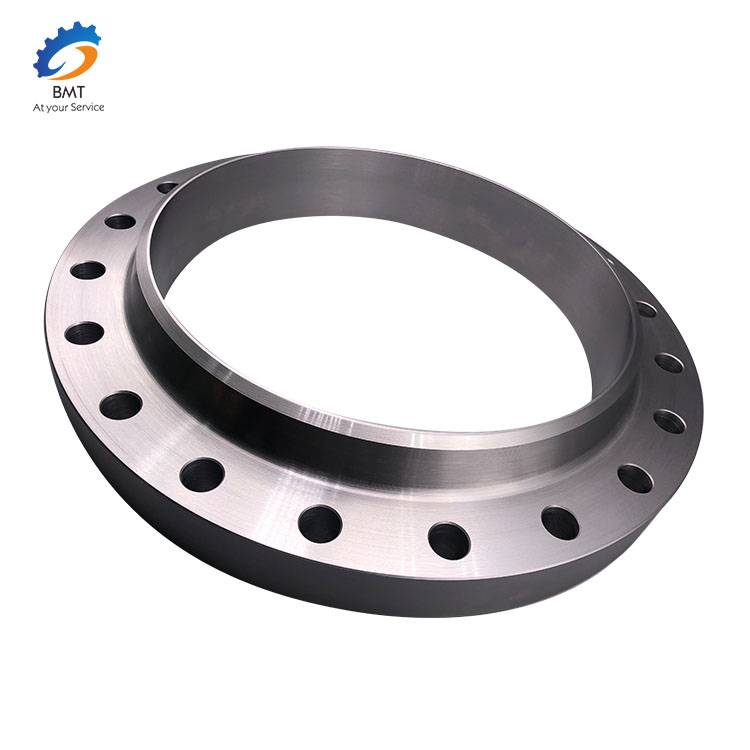

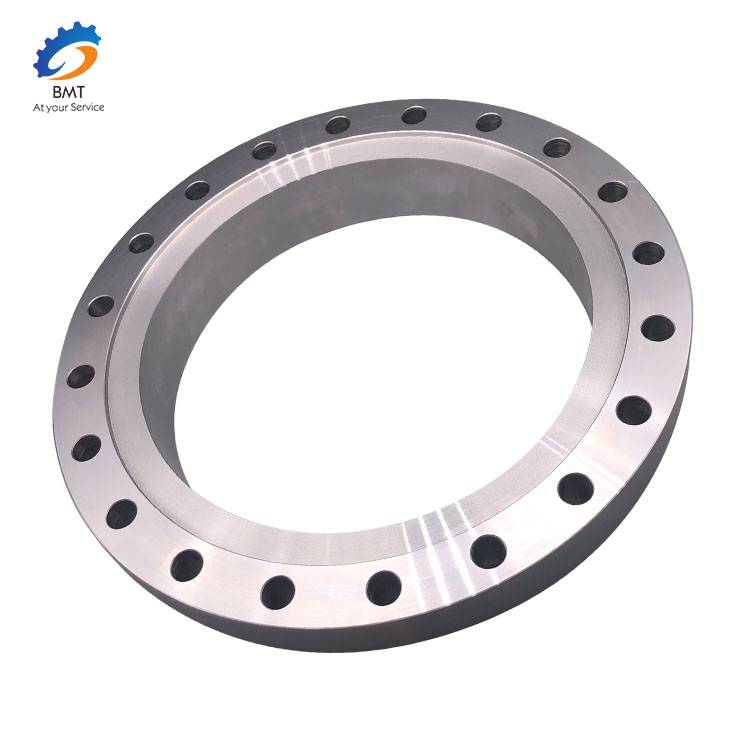

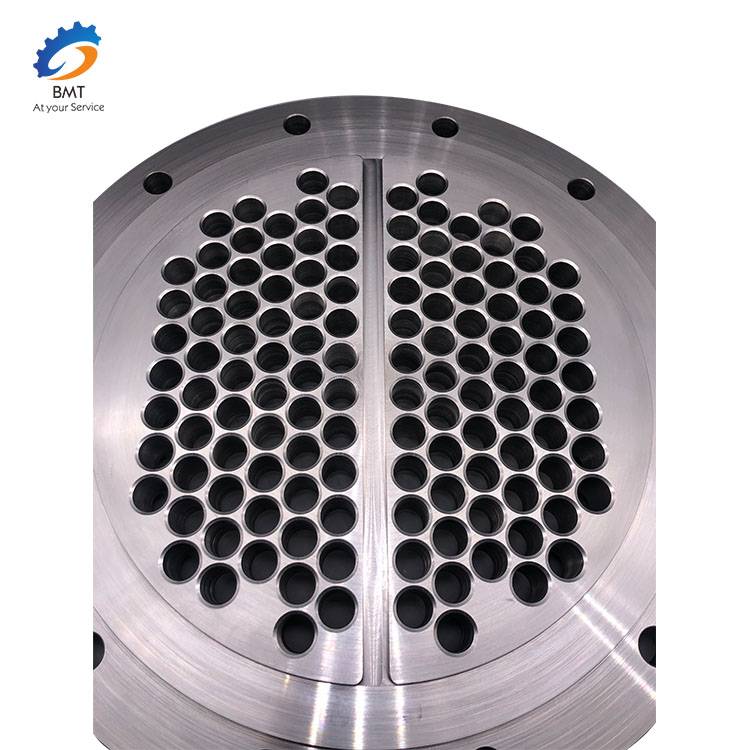

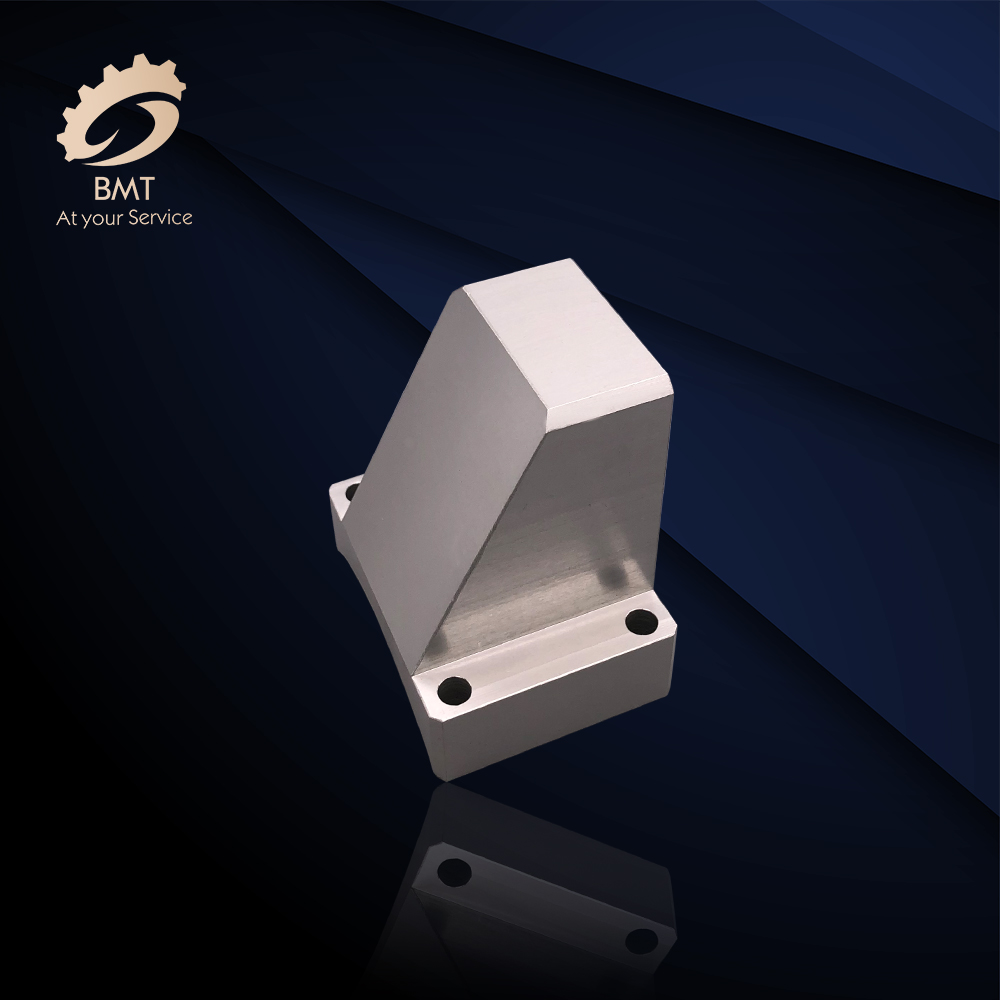

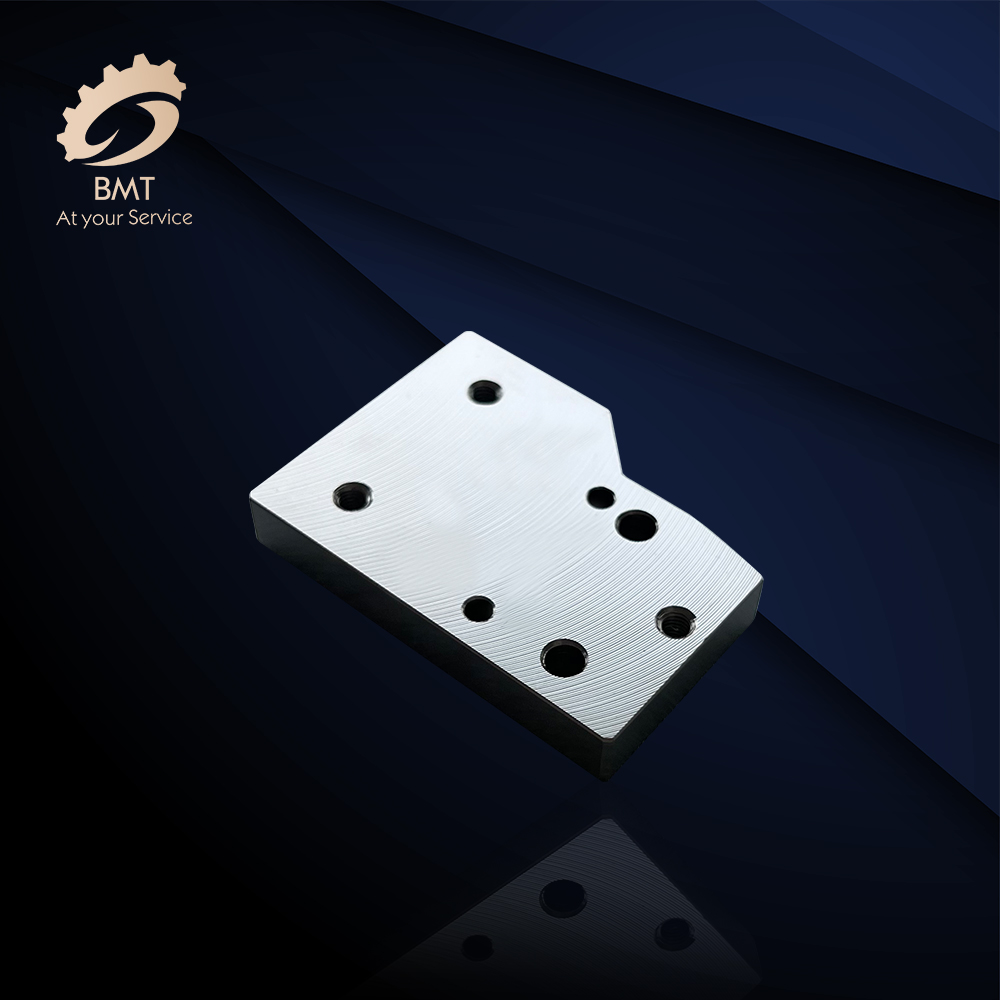

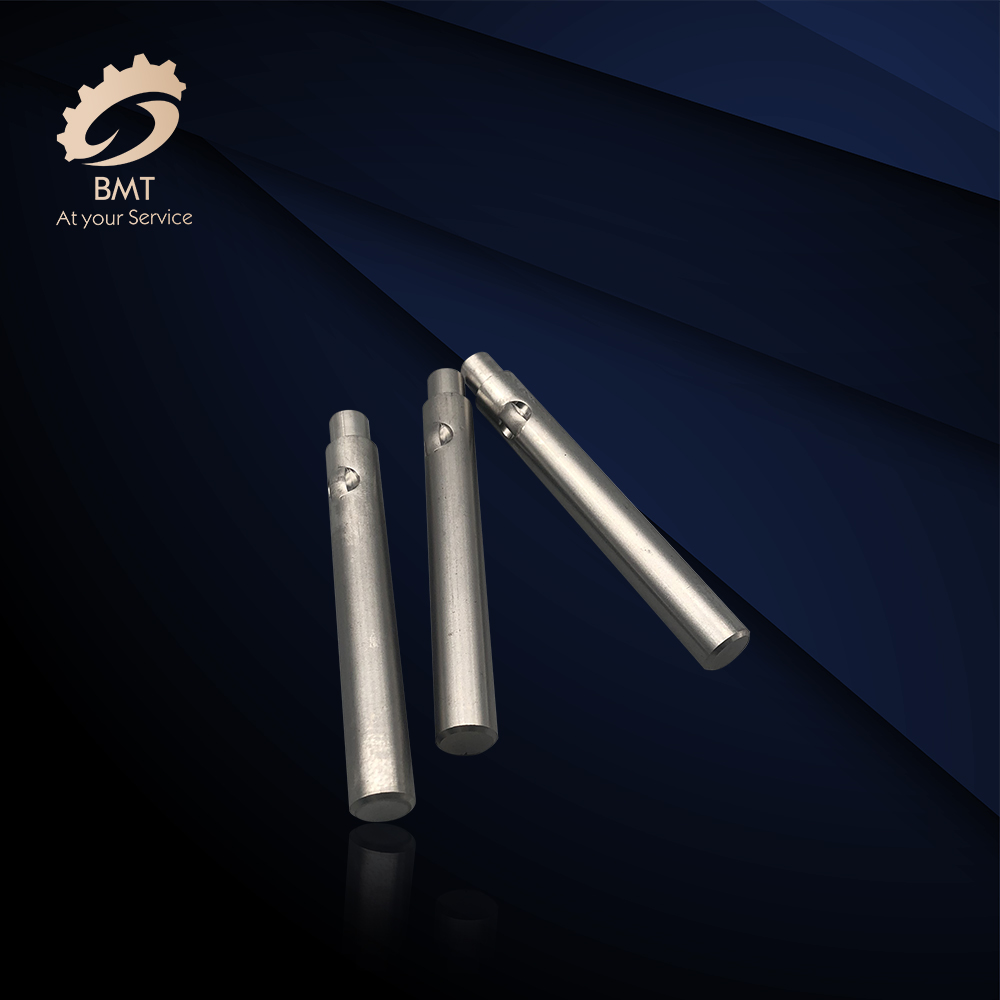

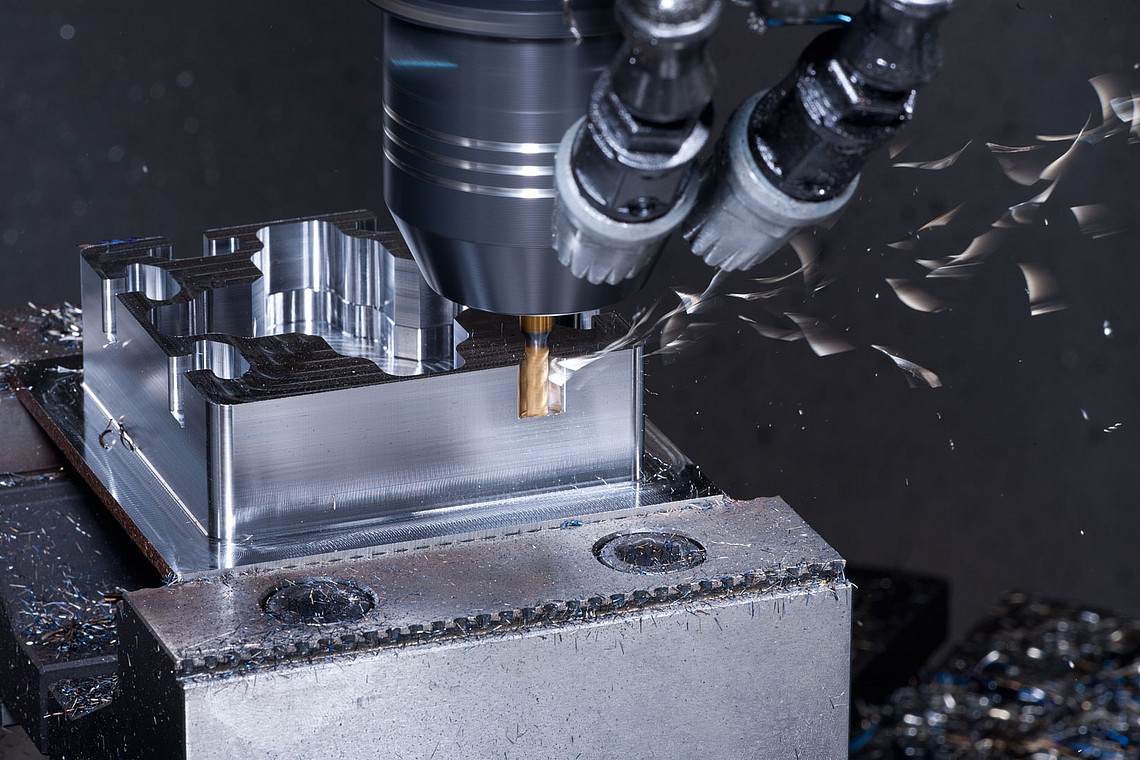

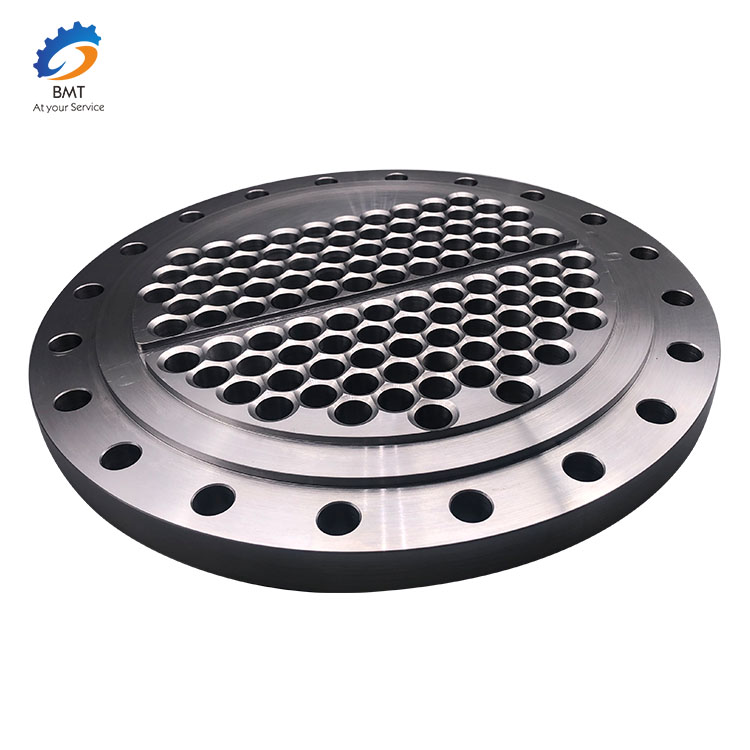

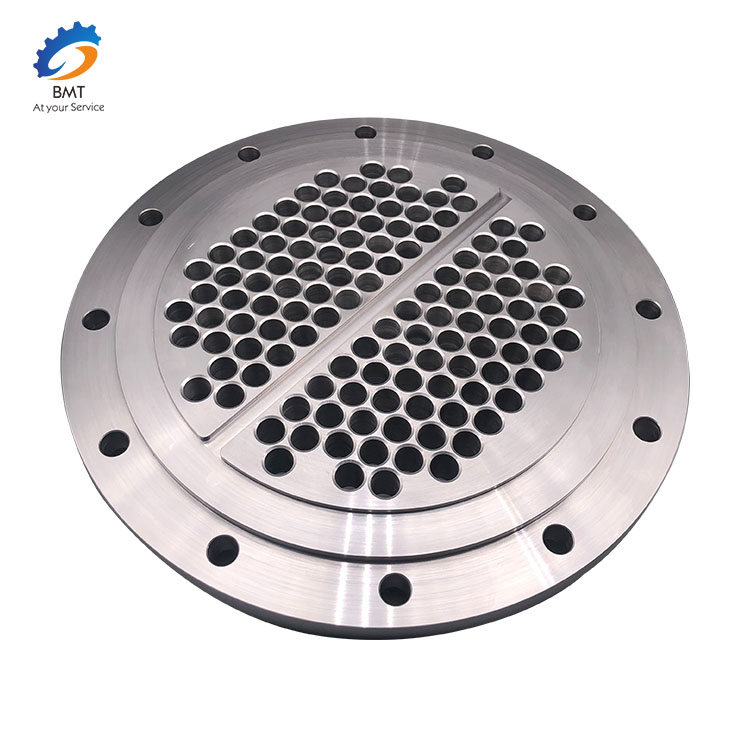

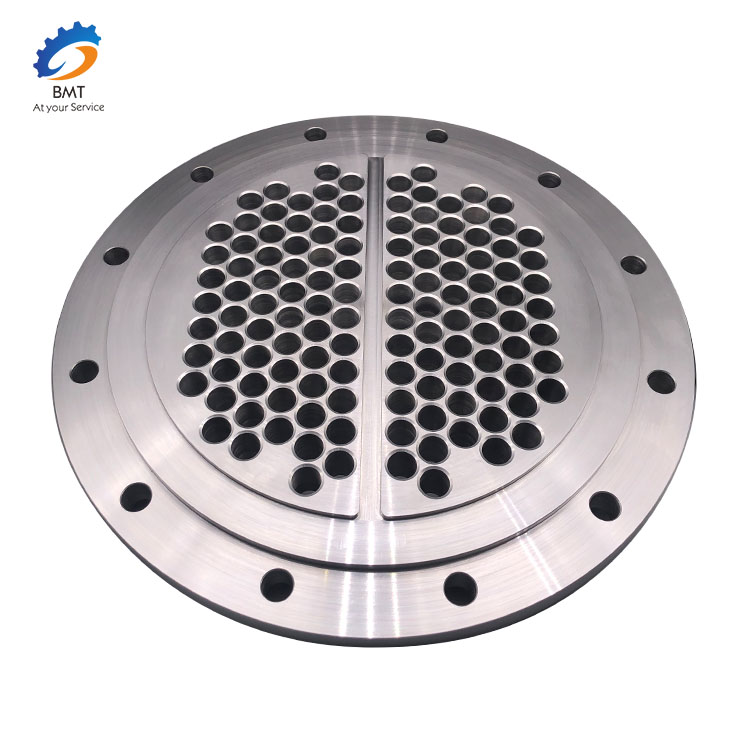

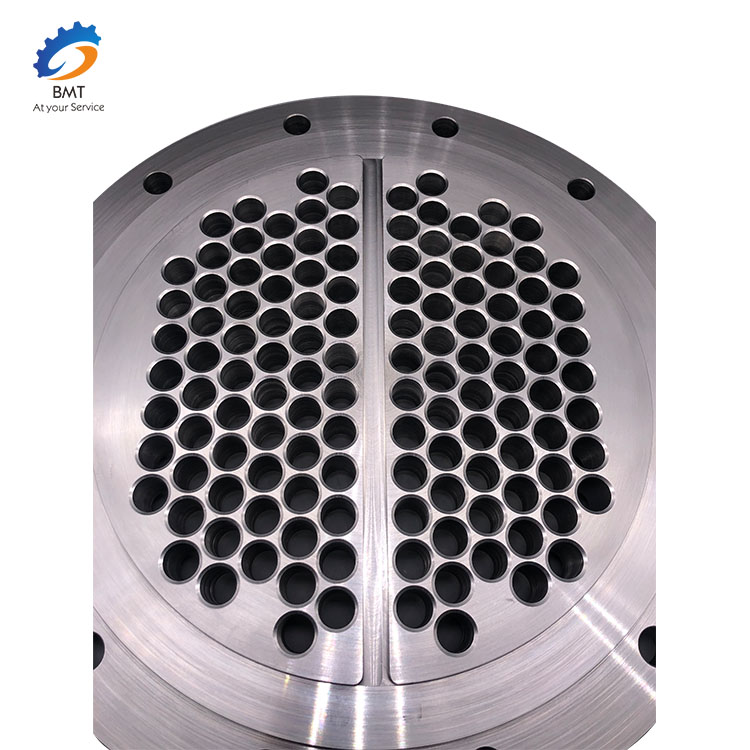

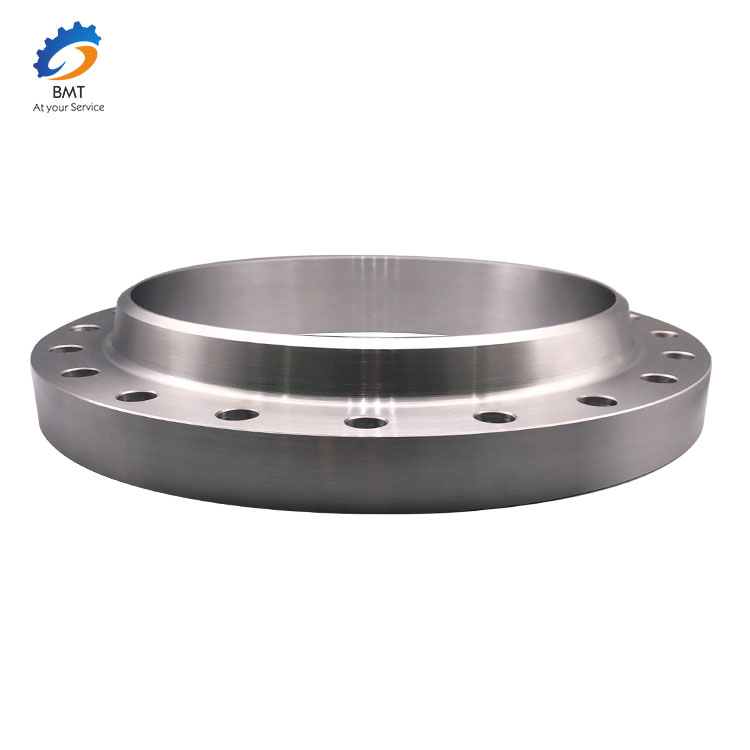

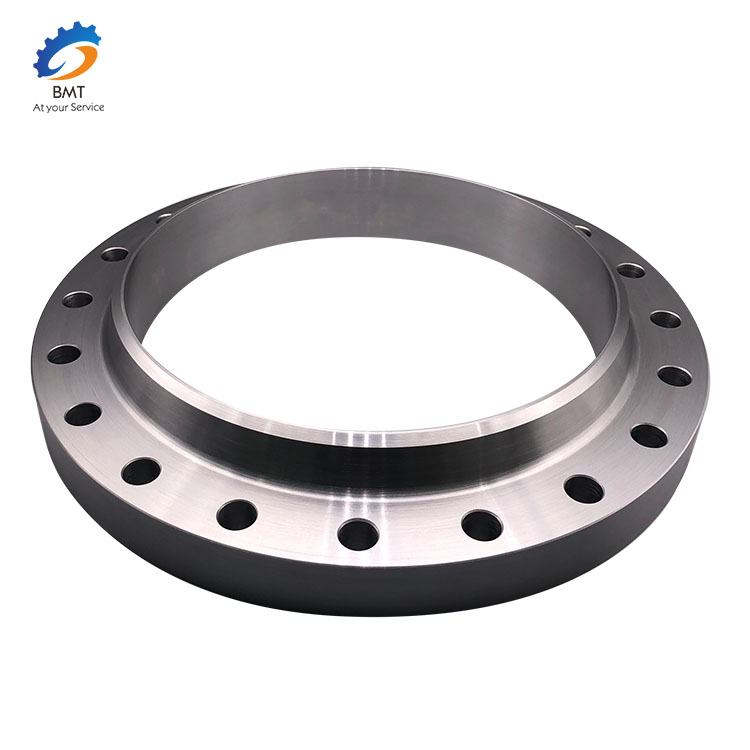

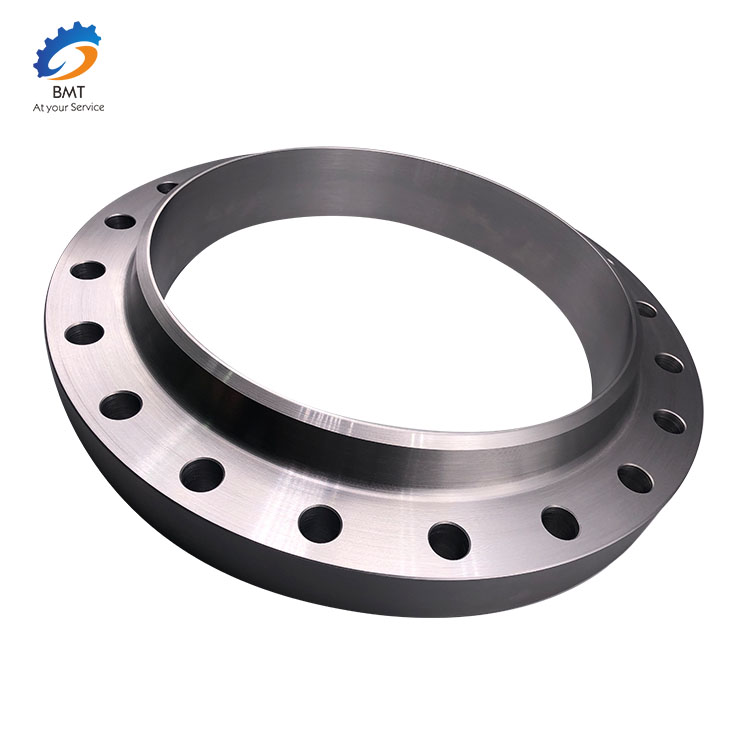

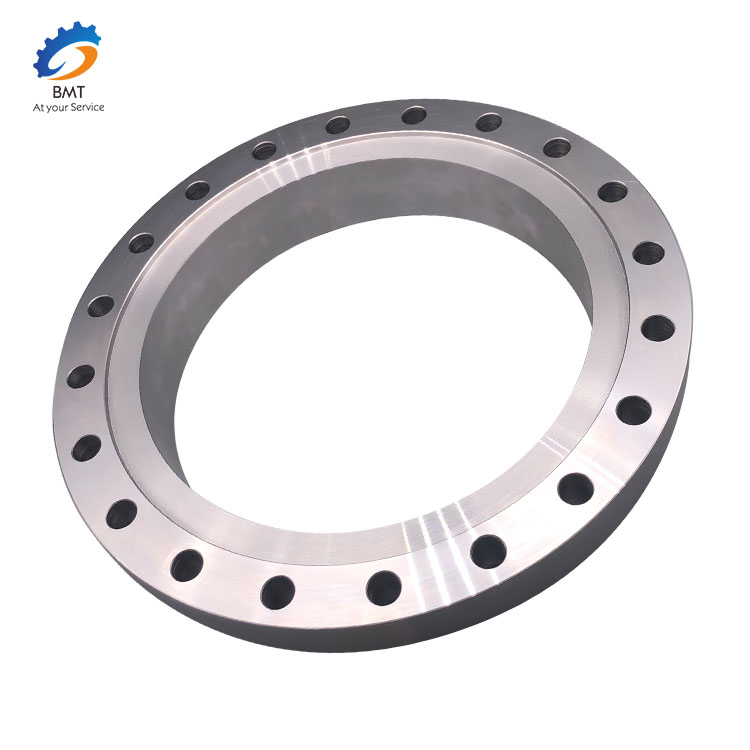

Custom Made CNC Machining Parts

Itekhnoloji yokulungiswa kwamalungu omatshini ibhekisa kwinkqubo yokutshintsha imilinganiselo okanye iipropathi zesixhobo sokusebenza ngesixhobo soomatshini. Ngokomahluko kwindlela yokucubungula, inokwahlulwa ibe yinkqubo yokusika kunye noxinzelelo.

Iindlela zokulungisa iindawo zoomatshini ikakhulu zibandakanya: ukujika, ukugaya, ukucwangcisa, ukufaka, ukugaya, ukubhola, ukudika, ukubethelwa, ukubethelwa kunye nezinye iindlela. Inokubandakanya ukusika ucingo, ukuphosa, ukubumba, i-electro-corrosion, i-powder processing, i-electroplating, kunye nonyango lobushushu njalo njalo.

1. Ukujika:

Kukho umatshini we-lathe othe nkqo kunye nomatshini we-lathe othe tye; izixhobo ezitsha zinomatshini we-CNC lathe, ubukhulu becala osebenza umzimba ojikelezayo;

2. Ukugaya:

Kukho ukungqusha ngokuthe nkqo kunye nokusila okuthe tye; izixhobo ezitsha zine-CNC yokusila, ekwabizwa ngokuba liziko lomatshini le-CNC, ubukhulu becala i-groove kunye nendawo yesicwangciso sokumila. Ewe kunjalo, inokuphinda iqhubekisele i-camber ngamazembe amabini okanye amathathu eCNC Machining Centre.

3. Ukucwangcisa:

Ubukhulu becala qhubekeka umphezulu wendawo yesicwangciso semilo. Phantsi kweemeko eziqhelekileyo, uburhabaxa bomphezulu abukho ngaphezu komatshini wokungqusha;

4. Ukufaka:

Inokuqondwa njengeplani ethe nkqo, ilungele ukusetyenzwa kwe-arc yesetyhula engagqibekanga.

5. Ukucola:

Kukho ukugaya inqwelomoya, ukugaya okusetyhula, ukugaya umngxuma ongaphakathi, kunye nokusila isixhobo, njl. njl.

6. Ukugrumba:

Ngokuqhelekileyo, kukulungiswa kwemingxuma.

7. Kuyadika:

Ubukhulu becala ngumngxuma okruqulayo ngokusebenzisa izixhobo ezikruqulayo okanye incakuba, kunye nokusetyenzwa kwedayamitha enkulu, umngxuma ochanekileyo ophezulu, kunye nokumila komcedo omkhulu.

8. Ukubetha:

Ubukhulu becala kukubetha ukubumba ngomatshini wokungqinga, onokugqobhoza umngxuma ongqukuva okanye omilise okhethekileyo.

9. Ukusika nokusarha:

Ikakhulu kukusika izinto ngomatshini wokusarha, osetyenziswa rhoqo kwinkqubo yokuvala.

Nawuphi na umatshini wenziwa ngamalungu amaninzi achanekileyo, ngaphandle kwamacandelo omatshini, umatshini awuphelelanga. Kungenxa yoko le nto iinxalenye zoomatshini zidlala indima ebalulekileyo kumashishini oomatshini.

Ngophuhliso lwe-automation, iteknoloji yokucubungula oomatshini nayo iqalile ukuzenzekelayo ulwalathiso lwendaleko eqhubekayo, kufuneka idlale indima ebalulekileyo kuphuhliso loluntu lwexesha elizayo, uyazi, amandla enkqubo yoomatshini kuphuhliso loqoqosho lwesizwe. Kwi-BMT, sisebenzisa itekhnoloji kakuhle kakhulu, ukuze sibonelele ngezona nxalenye zibalaseleyo zomatshini kubathengi bethu. Ukuba kukho into efunekayo, nceda uqhagamshelane nathi ngokukhawuleza.

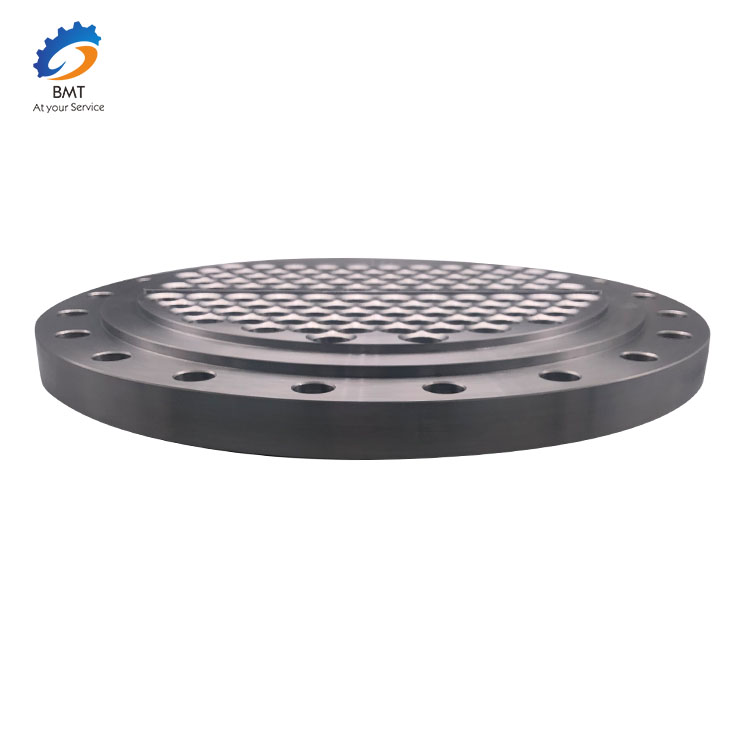

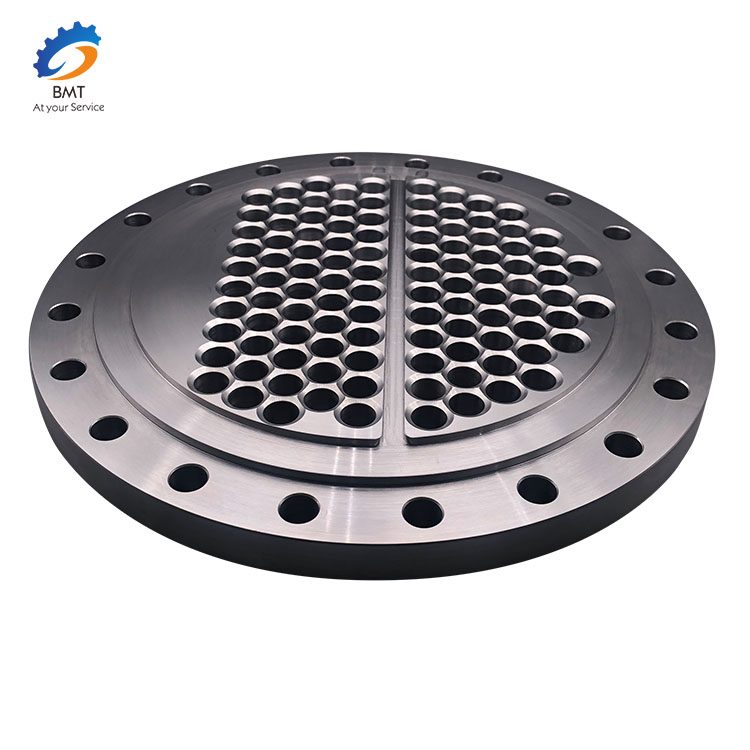

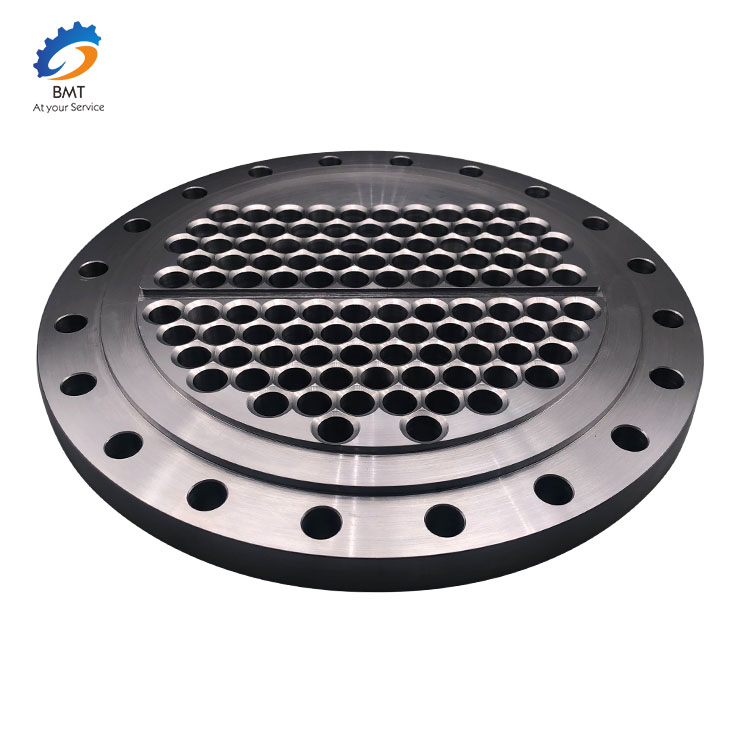

Ingcaciso yeMveliso

Ezinye iimveliso esizenzileyo