Iindidi ezahlukeneyo zokuSebenza koMatshini

Ngexesha lokwenziwa kwenxalenye, imisebenzi eyahlukeneyo yomatshini kunye neenkqubo ziyafuneka ukususa izinto ezingaphezulu. Le misebenzi idla ngokuba ngoomatshini kwaye ibandakanya izixhobo zokusika, amavili abrasive, kunye neediski, njl. njl. Imisebenzi yomatshini inokwenziwa kwiimilo ze-stock Mill njengemivalo kunye neeflethi okanye zinokuthi zenziwe kwiindawo ezenziwe ngeendlela zangaphambili zokuvelisa ezifana nokuphosa okanye ukuwelda. Ngenkqubela phambili yamva nje yokwenziwa kolwakhiwo, ukwenziwa komatshini sele kubhalwe mva nje njengenkqubo “yokuthabatha” ukuchaza ukuthatha kwayo imathiriyeli ukwenza inxalenye egqityiweyo.

Iindidi ezahlukeneyo zokuSebenza koMatshini

Iinkqubo ezimbini eziphambili zokutshiza zijika kunye nokugaya - zichazwe ngezantsi. Ezinye iinkqubo ngamanye amaxesha ziyafana nezi nkqubo okanye zenziwa ngezixhobo ezizimeleyo. I-drill bit, umzekelo, inokufakwa kwi-lathe esetyenziselwa ukujika okanye i-chucked kwi-drill press. Ngaxa lithile, kwakunokwahlulwa phakathi kokujika, apho inxalenye yayo ijikeleza, nokusila, apho isixhobo sijikeleza khona. Oku kuye kwafiphala ngandlel’ ithile ngokufika kwamaziko omatshini kunye namaziko okujika ayakwazi ukwenza yonke imisebenzi yomatshini ngamnye kumatshini omnye.

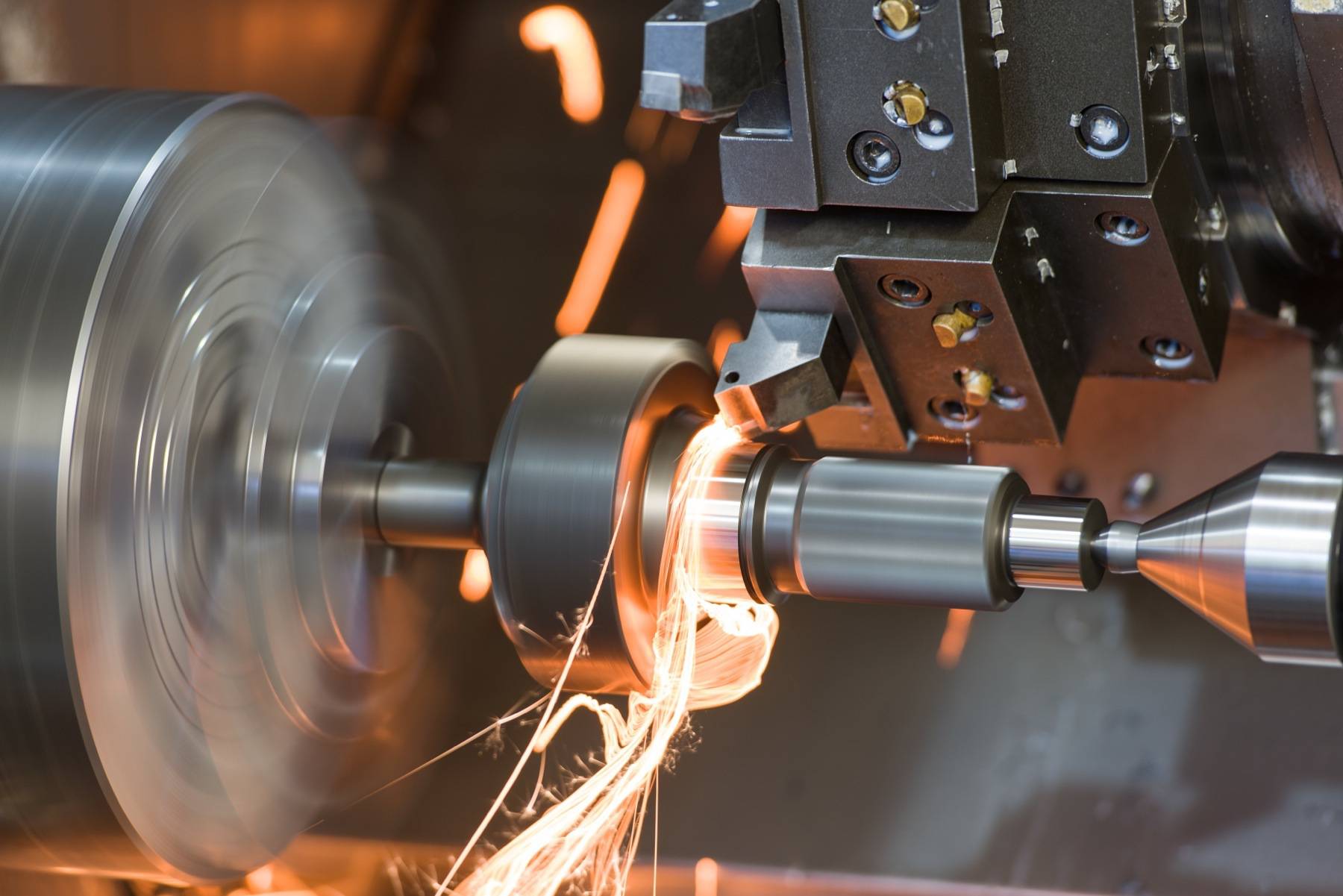

Ukujika

Ukujika yinkqubo yomatshini eyenziwa yilathe; i-lathe ijikeleza i-workpiece njengoko izixhobo zokusika zihamba ngaphaya kwayo. Izixhobo zokusika zisebenza kunye neentsimbi ezimbini zokunyakaza ukudala ukusika ngobunzulu obuchanekileyo kunye nobubanzi. Iileyile zifumaneka kwiindidi ezimbini ezahlukeneyo, uhlobo lwemveli, uhlobo lwencwadi, kunye ne-automated, uhlobo lweCNC.Inkqubo yokuguqula inokwenziwa nokuba kungaphandle okanye ngaphakathi kwempahla. Xa isenziwa ngaphakathi, yaziwa ngokuba "yi-boring" - le ndlela isetyenziswa ngokuqhelekileyo ukwenza amacandelo e-tubular. ngokuqhelekileyo yenziwa ngexesha lokuqala kunye nenqanaba lokugqibela lenkqubo yokujika. Ukujongana kungafakwa kuphela ukuba ileyibhile inesilayidi esifakelweyo. Yayisetyenziselwa ukuvelisa i-datum ebusweni be-casting okanye i-stock shape e-perpendicular kwi-axis ejikelezayo.

Iileyile zichongwa ngokubanzi njengenye yeentlobo ezintathu ezahlukeneyo - iileyile ze-turret, iileyile ze-injini, kunye neenjongo ezikhethekileyo. Iileyile ze-injini lolona hlobo luxhaphakileyo olufumaneka ekusetyenzisweni ngumashini jikelele okanye u-hobbyist. IiLathes zeTurret kunye neenjongo ezizodwa zisetyenziselwa usetyenziso olufuna ukwenziwa ngokuphindaphindiweyo kweenxalenye. I-turret lathe ibonisa umnini wesixhobo esenza ukuba umatshini enze imisebenzi yokusika ngokulandelelana ngaphandle kokuphazamiseka kumqhubi. Iileyile ezikhethekileyo zibandakanya, umzekelo, iileyile zediskhi kunye negubu, apho igaraji yeemoto ingasebenzisa ukujonga kwakhona umphezulu wamalungu ebrake.

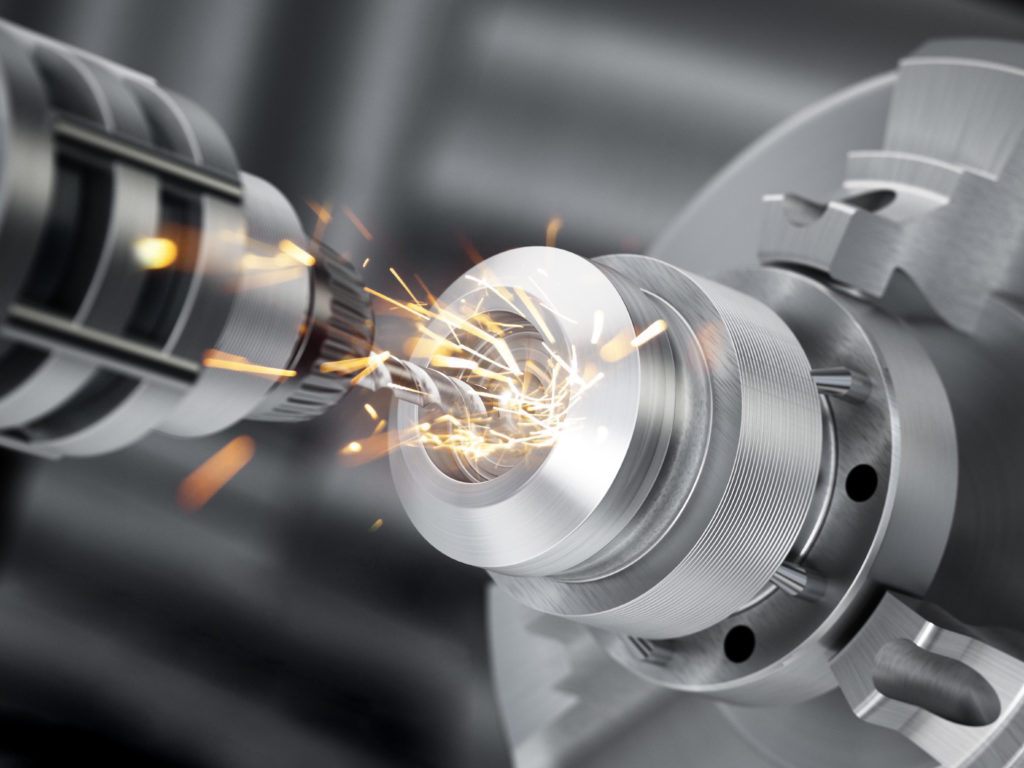

Amaziko e-CNC okuguqula i-mill-turn adibanisa intloko kunye nomsila we-lathes zendabuko kunye nee-axes zokuphotha ezongezelelweyo ukwenzela ukuba umatshini osebenzayo wamacandelo ane-symmetry ejikelezayo (i-impellers zepompo, umzekelo) ezidityaniswe nokukwazi ukusika ukuvelisa iimpawu ezinzima. Iigophe ezintsonkothileyo zinokudalwa ngokujikelezisa i-workpiece nge-arc njengoko i-milling cutter ihamba ngendlela eyahlukileyo, inkqubo eyaziwa ngokuba yi-5 axis machining.

Ukugrumba/Ukukruqula/Ukubuyisela kwakhona

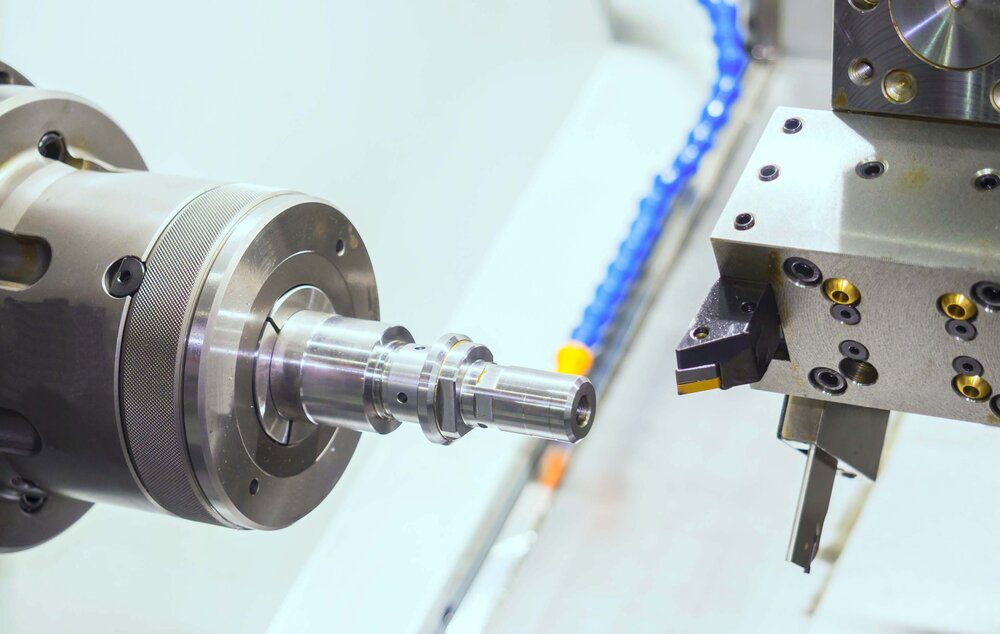

Ukubhobhoza kuvelisa imingxuma ye-cylindrical kwizinto eziqinileyo usebenzisa i-drill bits-yenye yezona nkqubo zibalulekileyo ze-machining njengoko imingxuma eyenziweyo idla ngokujoliswa ekuncedeni kwindibano. I-drill press isetyenziswa rhoqo kodwa amasuntswana anokuthi afakwe kwiileyile ngokunjalo. Kuninzi lwemisebenzi yokuvelisa, ukomba linyathelo lokuqala ekuveliseni imingxuma egqityiweyo, leyo ithi emva koko icofe, ihlaziywe, ikruquke, njl. Amasuntswana e-Drill aqhele ukusika imingxuma emikhulu kunobungakanani bawo begama kunye nemingxuma ekunganyanzelekanga ukuba ithe tye okanye ingqukuva ngenxa yokuguquguquka kwesuntswana kunye notyekelo lwalo lokuthatha indlela yokumelana okuncinci. Ngesi sizathu, ukugrumba kudla ngokuchazwa ubungakanani obungaphantsi kwaye kulandelwe ngomnye umsebenzi womatshini okhupha umngxuma ukuya kwidimension yawo egqityiweyo.

Nangona ukugrumba kunye nokukruqula kudla ngokubhideka, ukukruqula kusetyenziselwa ukulungisa imilinganiselo kunye nokuchaneka komngxuma ogrunjiweyo. Oomatshini abakruqulayo beza ngokwahlukeneyo ngokuxhomekeke kubungakanani bomsebenzi. Ilitye lokusila elithe nkqo lisetyenziselwa ukwenza umatshini omkhulu kakhulu, iicastings ezinzima apho umsebenzi ujika ngelixa isixhobo esikruqulayo sigcinwe simile. Iimilili ezinqamlekileyo kunye ne-jig borers zibamba umsebenzi omileyo kwaye zijikeleze isixhobo sokusika. Ukudika kuyenziwa nakwi-lathe okanye kwiziko lomatshini. Umsiki okruqulayo ngokuqhelekileyo usebenzisa inqaku elinye ukwenza umatshini wecala lomngxuma, evumela isixhobo ukuba sisebenze ngokungqongqo ngakumbi kune-drill bit. Imingxuma ene-Cored kwi-castings idla ngokugqitywa ngokukruqula.

Ukugaya

Ukugaya kusebenzisa ii-cutters ezijikelezayo ukususa izinto, ngokungafaniyo nemisebenzi yokuguqula apho isixhobo singasonti. Oomatshini bokusila bemveli babonisa iitafile ezishukumayo apho kugxunyekwe khona izinto zokusebenza. Kula matshini, izixhobo zokusika zimile kwaye itafile ihambisa izinto ukuze kucuthwe okufunwayo. Ezinye iintlobo zoomatshini bokungqusha babonisa zombini itafile kunye nezixhobo zokusika njengezixhobo ezishukumayo.

Imisebenzi emibini ephambili yokugaya kukugaya i-slab kunye nokungqusha ubuso. Ukungqusha ngesilebhu kusebenzisa imiphetho yeperipheral yesisiki sokusila ukwenza ukusika okucwangcisiweyo kumphezulu womsebenzi. Izitshixo ezikwishafti zinokusikwa kusetyenziswa umsiki ofanayo nangona lowo ucutheneyo kunesiqhelo umsiki we slab. Abasiki bobuso endaweni yoko basebenzise isiphelo sesisiki sokusila. Abasiki abakhethekileyo bayafumaneka kwimisebenzi eyahlukeneyo, njengabasiki bebhola-empumlo ezinokusetyenziswa ukuguba iipokotho zodonga olugobileyo.

Eminye yemisebenzi eyenziwa ngumatshini wokungqusha okwaziyo ukuyenza ibandakanya ukucwangcisa, ukusika, ukurhabula, ukuthunga, ukushona, njalo njalo, ukwenza umatshini wokungqusha ube ngomnye wezixhobo ezibhetyebhetye ngakumbi kwivenkile yomatshini.

Zine iindidi zoomatshini bokungqusha – oomatshini bokungqusha ngesandla, oomatshini bokungqusha obungaxutywanga, oomatshini bokusila behlabathi lonke, kunye noomatshini bokungqusha jikelele – kwaye babonisa nokuba ngabasiki abathe tye okanye abasiki abafakelwe kwi-axis ethe nkqo. Njengoko kulindelekile, umatshini wokusila wendalo yonke uvumela izixhobo zokusika ezithe nkqo nezithe tyaba, nto leyo eyenza ibe yenye yezona zixhobo zinzima kunye neziguquguqukayo zokugaya ezikhoyo.

Njengamaziko okuguqula, oomatshini bokugaya abakwazi ukuvelisa uluhlu lwemisebenzi kwinqanaba ngaphandle kokungenelela kwabaqhubi baxhaphake kwaye bahlala bebizwa ngokuba ngamaziko omatshini amileyo nathe tye. Zihlala zisekwe kwi-CNC.