Izinto ezichaphazela ukuntsonkotha kweCandelo

- Ubungakanani benxalenye

Ubungakanani bubodwa abuchazi ubunzima benxalenye, kodwa bunokuba ngumba. Khumbula ukuba, ngamanye amaxesha iindawo ezinkulu ezicwangcisiweyo azinamceli mngeni kunamalungu amancinci, antsokothileyo. Kwakhona, qwalasela ubungakanani beempawu zomntu ngamnye, njengoko oku kuchaphazela ubungakanani besixhobo sokusika esiza kusetyenziswa. Isixhobo esikhulu, esikhawulezayo sokusika sinokususa izinto ngokukhawuleza, ukunciphisa ixesha lomatshini.

- Ukusetyenzwa kwenxalenye

Inani lemisebenzi, ungenelelo kunye nokutshekishwa okufunekayo kwinqanaba kuya kuba nefuthe kwinxalenye entsonkothileyo. Ngokuxhomekeke kwijometri, ukugqiba kunye nokunyamezela njl., umyalelo wemisebenzi unokuba nzima, uchithe ixesha kunye neenkcukacha. Umzekelo, inxalenye entsonkothileyo inokufuna uhlengahlengiso oluninzi kunye nongenelelo lwezandla. Ngamanye amaxesha, i-5 axis okanye i-mill-turn machine ingaba ngowona matshini ufanelekileyo, umzekelo, ukuba kubiza ukuvelisa okanye kufuna iindleko ezincinci.

- Ukunyamezela inxalenye

Ukunyamezela inxalenye kunokuchaphazela ukhetho lomatshini we-CNC osetyenziswayo kwaye unokuchaphazela iindleko kunye nexesha lokukhokela. Ukunyamezela okufikelelekayo kukwachaphazeleka kwizinto eziphathekayo, isantya somatshini kunye nezixhobo zokusebenza. Ukubeka nje, okukhona ukunyamezelana kuqina, kokukhona inxalenye yakho iya kuba neendleko. Ukunyamezela okuphezulu kuvumela ukuchaneka okungakumbi, kodwa kunokubandakanya iinkqubo ezongezelelweyo, imisebenzi, kunye nezixhobo kunye noomatshini, ngoko ke ukongeza kwiindleko.

Iintlobo zokugqiba

- Ukuqhushumba kwamaso

I-Bead Blasting ibandakanya ukususwa kwayo nayiphi na idiphozithi yomphezulu okanye ukungafezeki kwinxalenye ukuze kugqitywe ngendlela efanayo, egudileyo. Amaso amile okwengqukuva aqinisekisa ukugqibezela okungaguqukiyo kwaye asetyenziswa ngokuqhelekileyo ukunika isiphelo sematt. Amaso acolekileyo angasetyenziselwa ukugqibezela okufana ne-satin okanye okubuthuntu.

- Anodized ugqiba

Ukugqitywa kwe-Anodized kunika i-coat-resistant-resistant coating, edla ngokufumaneka kwinani lemibala. I-Anodizing ibonakala ngokucacileyo, kwaye umaleko uhlala ubhityile ngoko qiniseka ukuba uqwalasele amanqaku omatshini we-CNC kumphezulu.

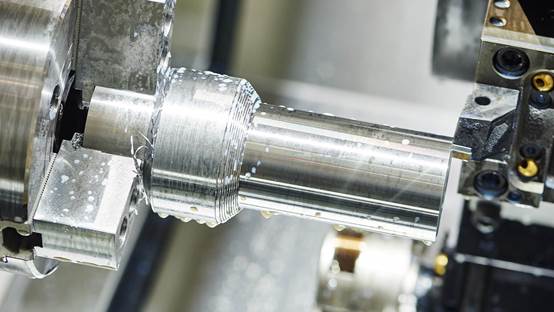

- Njengomatshini

Esinye isiphelo siya kushiya uburhabaxa bomphezulu njengoko isiqwenga sisenziwa ngoomatshini. Uburhabaxa benkonzo ngqo bumiselwa kusetyenziswa ixabiso likaRa. Ngokuqhelekileyo uburhabaxa bomphezulu beendawo ezimatshini ze-CNC yiRa 1.6-3.2µm.

Iingxelo zoHlolo lwe-CMM

Yintoni ingxelo yeCMM kwaye kutheni ndiyifuna?

Ukuhlolwa komatshini wokulinganisa ulungelelwaniso (CMM) kubandakanya ukusebenzisa umatshini wokulinganisa wokulungelelanisa ukuhlola imilinganiselo yenxalenye ukuze kuqinisekiswe ukuba inxalenye iyahlangabezana neemfuno ezithile zokunyamezelana. Umatshini wokuMeta ngokuNxibelelanisa usetyenziselwa ukulinganisa umgangatho kunye neempawu zento.

Ukuhlolwa kwe-CMM kuya kufuneka ukulinganisa iindawo ezinzima ngakumbi ukuqinisekisa ukuba zihambelana neenkcukacha. Zihlala zibandakanyiwe kwiindawo ezichanekileyo kakhulu apho umgangatho wokugqibela kunye nokuchaneka kuyadingeka. Ngeli xesha, ukugqitywa okugudileyo komphezulu kuya kuhlolwa kwakhona ukuqinisekisa ukuba kuchanekile kwimizobo kunye noyilo.

I-CMM isebenza ngokusebenzisa iprobe elinganisa amanqaku kwindawo yokusebenza. Ii-ax ezi-3 zenza inkqubo yokulungelelanisa yomatshini. Enye inkqubo yinkqubo yolungelelwaniso lwenxalenye, apho i-axes ezi-3 zihambelana/zihambelana neempawu kunye nedatha yendawo yokusebenza.

Izibonelelo zoHlolo lweCMM

Uhlolo lwe-CMM luya kwenziwa njengoko kwaye xa lufunwa, kwaye ngamanye amaxesha luya kuba sisinyanzelo. Iingxelo zoHlolo lwe-CMM zinokugcina ixesha kunye nokunciphisa iindleko eziphezulu ngokuqinisekisa ukuba inxalenye yenziwe ngokuchanekileyo kuyilo. Oku kuqinisekisa ukuba akukho nto ishiywe ngethuba kwaye nakuphi na ukutenxa kuyilo okanye iziphene zifunyenwe phambi kokuthunyelwa.

Ngokuxhomekeke kwishishini, ukutenxa kwiinkcukacha kunokuba yingozi (Umzekelo, imboni yezonyango, okanye imboni ye-aerospace.) Olu vavanyo lokugqibela lokulawula umgangatho lunokunika iziqinisekiso ngaphambi kokuba inxalenye isayinwe kwaye ihanjiswe kumxhasi.