Siyazi ukuba siphumelela kuphela ukuba sinokuqinisekisa ukhuphiswano lwethu lwethegi edibeneyo kunye nomgangatho ophezulu onenzuzo ngaxeshanye kwiiNkampani zokuVelisa.China Custom Made CNC Machining/ Ukuguqula iAluminiyam / iNsimbi / iTitanium / iNsimbi eNgatyiwayo / ubhedu / iPlastiki / iNqanawa yeeMoto zeBrass, sinokukubonisa elinye lawona maxabiso athengisayo akhuphisanayo kunye nomgangatho olungileyo, kuba siye saBafaneleka ngakumbi! Ngoko akufanele ungathandabuzi ukusitsalela umnxeba.

Siyazi ukuba siphumelela kuphela ukuba sinokuqinisekisa ukhuphiswano lwethu lwethegi edibeneyo kunye nomgangatho ophezulu onenzuzo ngaxeshanyeChina Custom Made CNC Machining, CNC Machining Turning Aluminium, Iimveliso zethu ziyaziwa ngokubanzi kwaye zithenjwa ngabasebenzisi kwaye zinokuhlangabezana ngokuqhubekayo nokuphuhlisa iimfuno zoqoqosho nezentlalo. Samkela abathengi abatsha nabadala abavela kuzo zonke iinkalo zobomi ukuba baqhagamshelane nathi kubudlelwane beshishini elizayo kunye nokuzuza impumelelo efanayo!

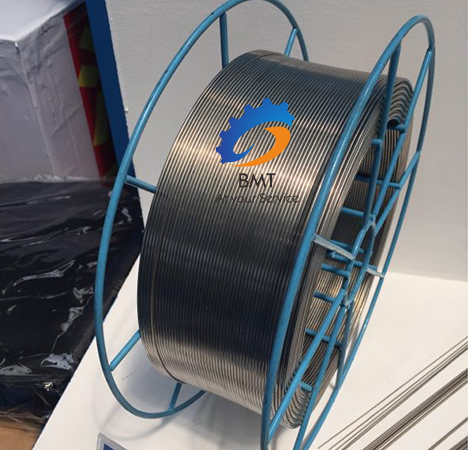

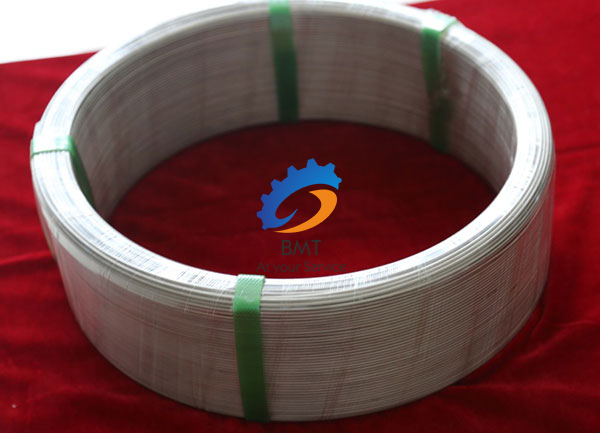

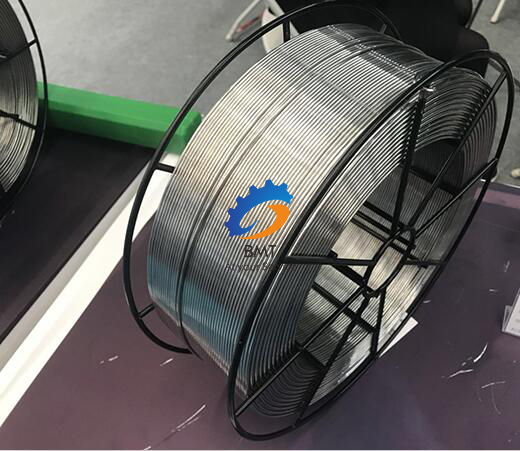

Iingcingo zeTitanium kunye neTitanium Alloy

I-titanium ecocekileyo yintsimbi emhlophe esiliva, eneempawu ezininzi ezintle. I-Titanium inoxinano lwe-4.54g/cm3, I-43% ilula kunentsimbi kwaye inzima kancinci kune-magnesium yensimbi eqaqambileyo. Kodwa amandla oomatshini aphantse alingane nentsimbi, yomelele ngokuphindwe kabini kune-aluminiyam kwaye yomelele ngokuphindwe kahlanu kune-magnesium. I-Titanium imelana nobushushu obuphezulu kwaye inendawo yokunyibilika ye-1942K, iphantse ibe yi-1000K ngaphezulu kwegolide kwaye iphantse ibe yi-500K ngaphezulu kwentsimbi.

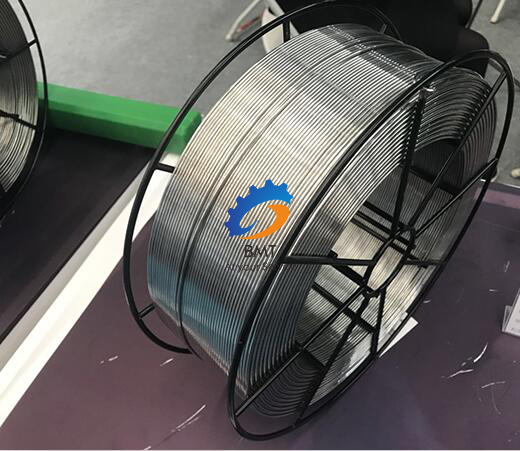

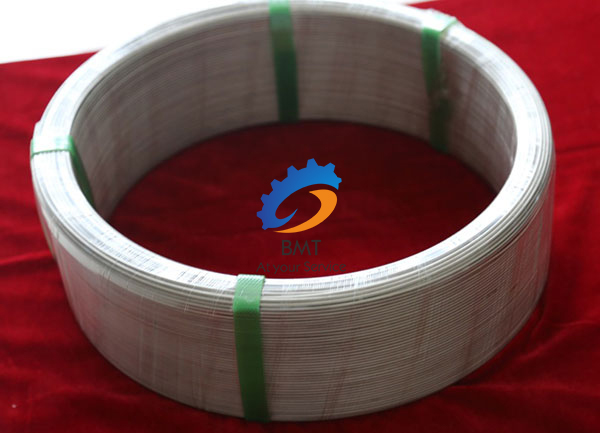

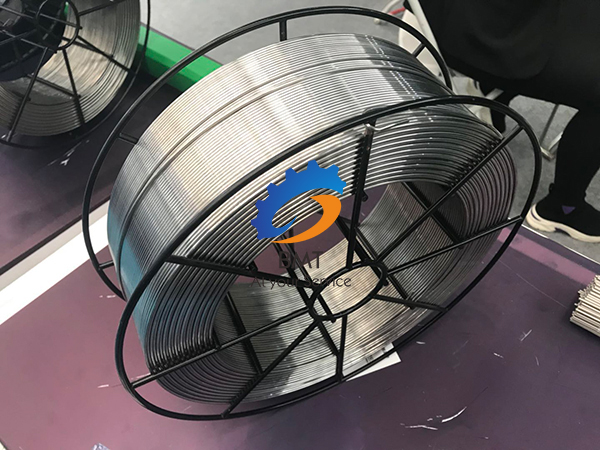

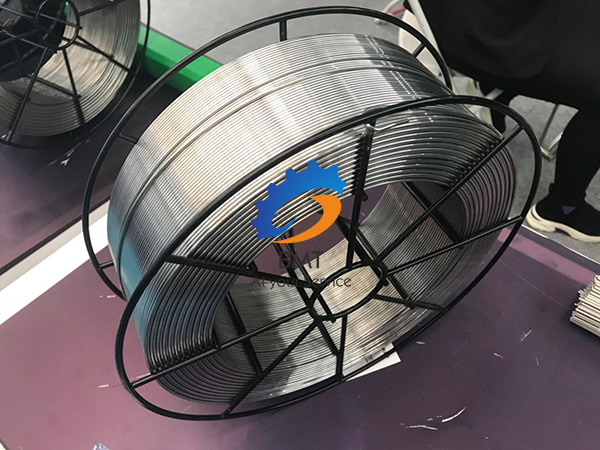

Ucingo lwe-titanium lwahlulwe lwaba: ucingo lwe-titanium, i-titanium alloy wire, i-titanium eyeglass wire, ucingo lwe-titanium oluthe tye, ucingo lwe-titanium olusulungekileyo, ucingo lwe-titanium welding, ucingo lwe-titanium olujingayo, ucingo lwe-titanium disk, ucingo olukhanyayo lwe-titanium, ucingo lwe-titanium yonyango, i-titanium nickel alloy wire. .

Iimpawu zeTitanium zocingo

A. Iimpawu zocingo lwe-Titanium: φ0.8-φ6.0mm

B. Iimpawu zocingo lwetitanium kwiiglasi: φ1.0-φ6.0mm ucingo olukhethekileyo lwetitanium

C. Iimpawu zocingo lwe-Titanium: φ0.2-φ8.0mm ngokuxhoma okukhethekileyo

Umgangatho:GB/T,GJB,AWS,ASTM,AMS,JIS

IBanga leTitanium Wire

GR1, GR2, GR3, GR5, GR7, GR9, GR11, GR12, GR16, njl.

Imimandla yokusetyenziswa kocingo lweTitanium

Ishishini lomkhosi, ezonyango, iimpahla zemidlalo, iiglasi, amacici, i-headwear, i-electroplating ejingayo, i-welding wire kunye namanye amashishini.

State of Titanium ngocingo

Imeko yokuphola (M)

Imeko yokusebenza eshushu (R)

Indawo yokusebenza ebandayo (Y)

(Annealing, Ultra-Generation Testing)

Umphezulu wocingo lweTitanium

Umphezulu wokuchola okanye ukhanyise umphezulu

Ucingo lwe-Titanium lwenza i-carbide ezinzileyo enobunzima obuphezulu kunye nekhabhoni. Ukukhula komaleko we-carbonized phakathi kwe-titanium kunye nekhabhoni kumiselwa yisantya sokusasazwa kwe-titanium kumaleko we-carbonized.

I-solubility yekhabhoni kwi-titanium incinci, ifikelela kwi-0.3% kwi-850X: kwaye iyancipha ukuya malunga ne-0.1% kwi-600C B Ngenxa yokunyibilika okuphantsi kwekhabhoni kwi-titanium, ukuqina komphezulu kufezekiswa kuphela nge-titanium carbide layer kunye ne-akimbo yayo. umaleko ongezantsi. I-Carburizing kufuneka yenziwe phantsi kwemeko yokususwa kwe-oksijini, ngenxa yokuba ukuqina komphezulu womgangatho womgubo oqhelekileyo usetyenziselwa intsimbi ye-carburizing ngokubhekiselele kumphezulu we-carbon monoxide okanye i-carbon monoxide equlethe i-carbon monoxide ukuya kwi-2700MPa kunye ne-8500MPa, kunye nomnatha. Kulula ukuyixobula.

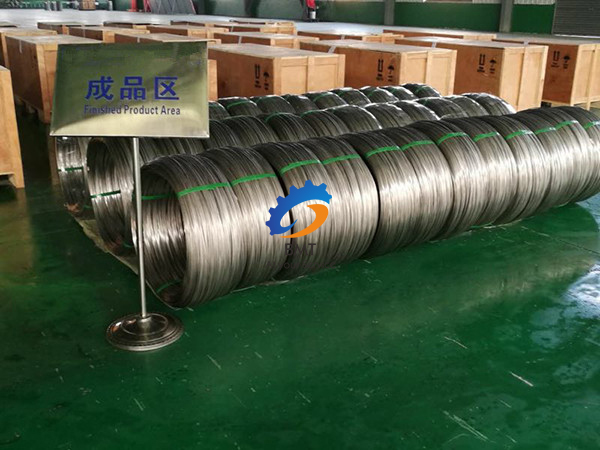

Ukwakheka kweMichiza yeMathiriyeli ekhoyo

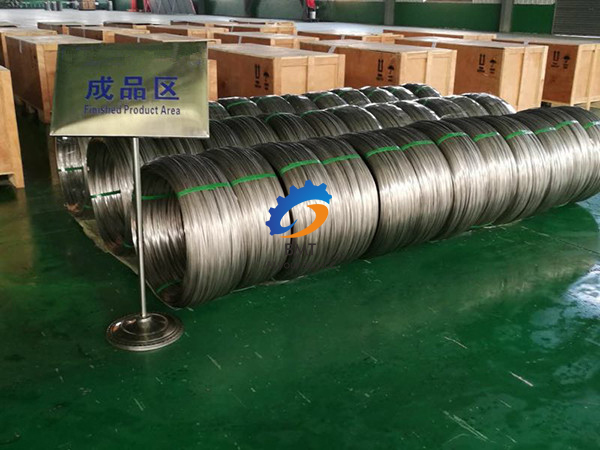

Imveliso (Ubuninzi kunye neMini encinci yoMyalelo):Unlimited, ngokomyalelo.

Ixesha lokukhokhela:Ixesha lokukhokela ngokubanzi ziintsuku ezingama-30. Nangona kunjalo, kuxhomekeke kwisixa somyalelo ngokufanelekileyo.

Ezothutho:Indlela jikelele yothutho luLwandle, ngoMoya, nge-Express, ngoLoliwe, oya kunyulwa ngabathengi.

Ukupakisha:

- Umbhobho uphela ukuba ukhuselwe ngeplastiki okanye i-caps cardboard caps.

- Zonke izifakelo kufuneka zipakishwe ukukhusela iziphelo kunye nokujongana.

- Zonke ezinye iimpahla ziya kupakishwa ngeephedi zogwebu kunye nokupakishwa kweplastiki ehambelanayo kunye neekesi zeplywood.

- Nawuphi na umthi osetyenziselwa ukupakisha kufuneka ulungele ukuthintela ukungcoliseka ngokudibana nezixhobo zokuphatha.

.jpg)

Ngokwahlukileyo, phantsi kwemeko ye-deoxygenation okanye i-decarburization, umgca omncinci we-titanium carbide unokuqulunqwa xa i-carburized in charcoal. Ubunzima bolu luhlu yi-32OUOMpa, ehambelana nobunzima be-titanium carbide. Ubunzulu bomaleko we-carburizing ngokubanzi bukhulu kunobo bomaleko we-nitriding xa i-nitriding isetyenziswa phantsi kweemeko ezifanayo. Ngaphantsi kwemeko yokutyetyiswa kwe-oksijeni, umphumo wokufunxa i-oksijini kubunzulu obunzima kufuneka uqwalaselwe. Kuphela phantsi kwemeko yobunzima obuncinci kakhulu apho amandla aneleyo ancamathelayo anokwakheka ngokufaka i-carburizing powder kwi-vacuum okanye kwi-argon-methane emoyeni. Ngokwahlukileyo koko, ukusetyenziswa kwe-agent ye-gas carburizing inokwenza umaleko oqinileyo we-titanium carbide oqinileyo ngokukodwa. Kwangaxeshanye, ukuqina ukusasazeka kwakheka kwiqondo lobushushu phakathi 950T: yaye 10201:. Ngokunyuka kobunzima bomaleko, umaleko we-TiC uba brittle kwaye uthande ukugqabhuka. Ukuze ugweme ukungena kwi-carbon inclusions kwi-TiC layer ngenxa yokuchithwa kweReane, i-gas carburizing kufuneka iqhutywe kwi-gas engasebenziyo kunye ne-additive dose emiselweyo malunga ne-2% yeReane. Ukuqina komphezulu osezantsi kufumaneka xa imethane ifakwe i-carburized nge-propane additives. Xa i-bonding force ifikelela kwi-OKPA kunye ne-gas carburized propane isetyenzisiweyo, nangona umlinganiselo obunzima bomaleko obunzima bubhityile kakhulu, unokumelana nokunxiba. I-Hydrogen ifunxwa yi-arhente ye-carburizing yegesi, kodwa kufuneka isuswe kwakhona ngexesha lokucoca i-vacuum.China Custom Made CNC Machining/ Ukuguqula iAluminiyam / iNsimbi / iTitanium / iNsimbi eNgatyiwayo / ubhedu / iPlastiki / iNqanawa yeeMoto zeBrass, sinokukubonisa elinye lawona maxabiso athengisayo akhuphisanayo kunye nomgangatho olungileyo, kuba siye saBafaneleka ngakumbi! Ngoko akufanele ungathandabuzi ukusitsalela umnxeba.

IiNkampani zokuVelisa eTshayina ngokweSiko elenziwe ngoMatshini we-CNC,CNC Machining Turning Aluminium, Iimveliso zethu ziyaziwa ngokubanzi kwaye zithenjwa ngabasebenzisi kwaye zinokuhlangabezana ngokuqhubekayo nokuphuhlisa iimfuno zoqoqosho nezentlalo. Samkela abathengi abatsha nabadala abavela kuzo zonke iinkalo zobomi ukuba baqhagamshelane nathi kubudlelwane beshishini elizayo kunye nokuzuza impumelelo efanayo!