IiNkqubo zokuFakwa kweMetal yeSiko

I-Custom Sheet Metal Fabrication ibonakala intsonkothile kancinane njengoko inokwakhiwa kuzo zonke iintlobo zeemilo, kodwa yonke inkqubela-phambili yokwenziwa kwemveliso inokunqunyulwa nje ibe ngamanyathelo amathathu njengalapha ngezantsi.

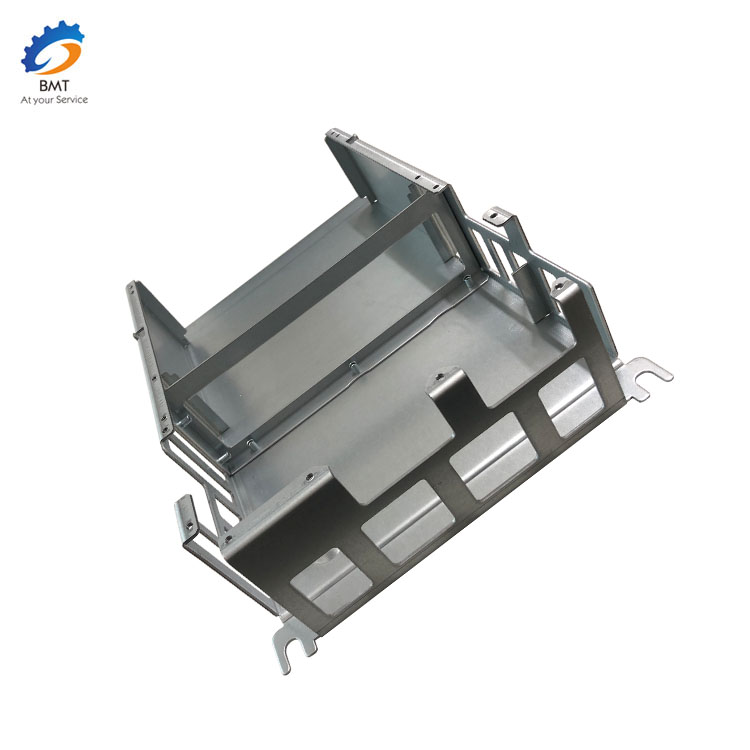

Eyokuqala yinkqubela yokusika ekwabizwa ngokuba yinkqubela yokususwa kwezinto. Kule nkqubela phambili, kukho iindlela ezininzi ezahlukeneyo ezibandakanya ukusika i-laser, ukusika ijethi yamanzi, ukusika iplasma, kunye nokusika ipunch. Phakathi kwazo zonke, ukusika kwe-laser kubandakanya ukusetyenziswa kwe-laser ukufezekisa ukusikwa okuchanekileyo kwishiti lesinyithi. Ichaneke ngakumbi kwaye inamandla ngakumbi kunezinye iinkqubo zokusika ubukhulu obukhulu kwaye icinga imathiriyeli yesinyithi, eyona ndlela ixhaphakileyo kumzi-mveliso wethu.

Ukusika i-Punch, kwelinye icala, yenye indlela eqhelekileyo kwaye ilungele ukusetyenziswa kwisicelo sobungakanani obuncinci.

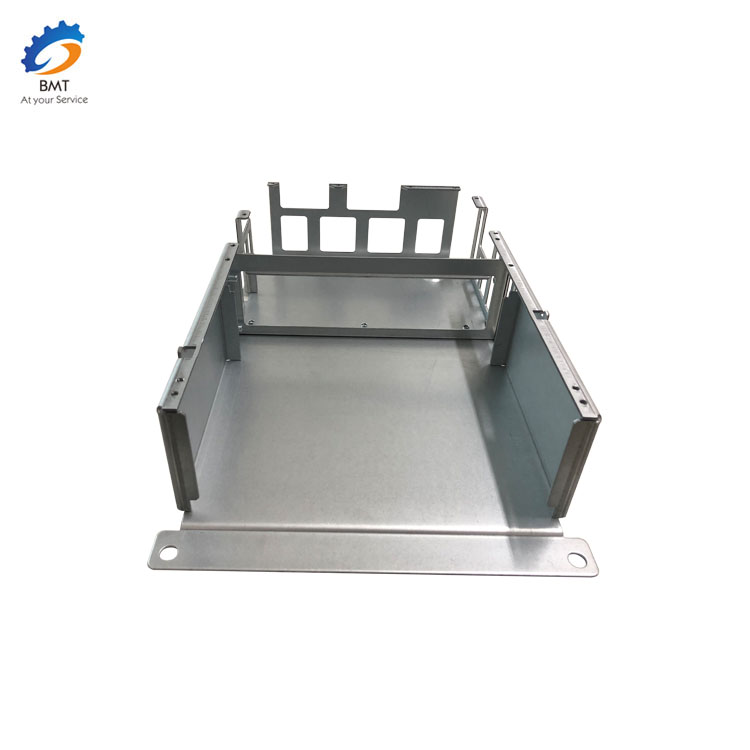

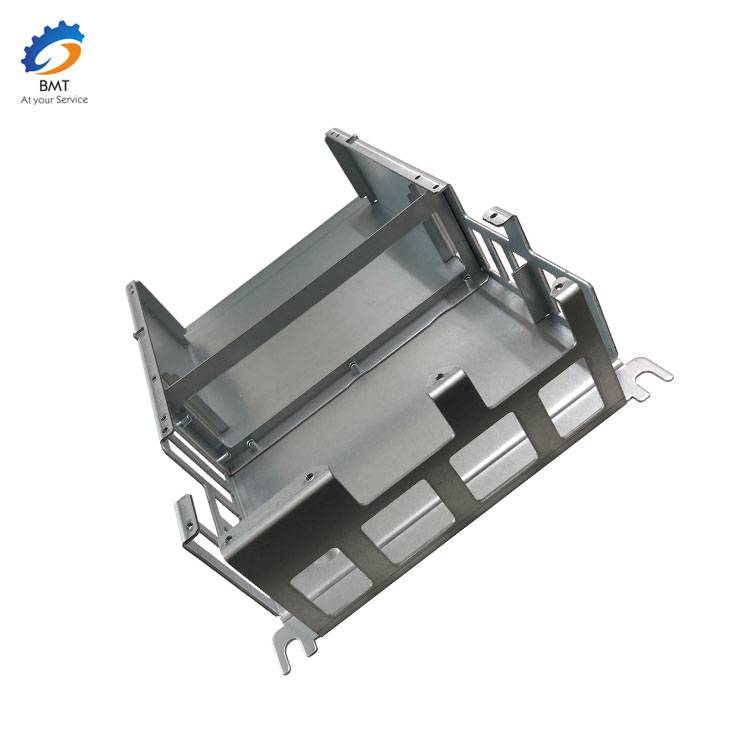

Emva kokusikwa, sinokwakheka okubizwa ngokuba yi-deformation yezinto eziphathekayo. Kukho iindlela ezininzi zokubumba ezibandakanya ukuqengqeleka, ukusonta, ukugoba, ukunyathela, kunye nokuwelda.

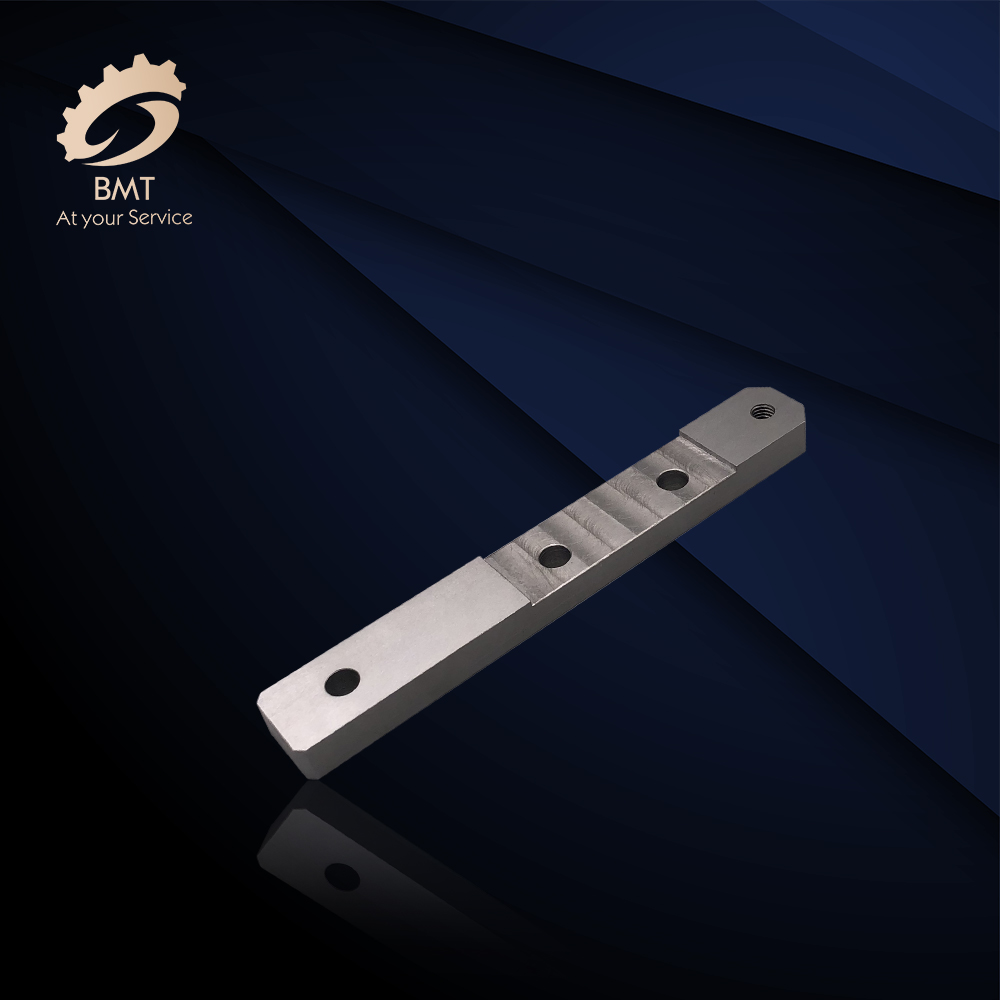

Okokugqibela, kuyagqitywa. Oku kubhekiselele kumalungu omzekelo agudiswayo nge-abrasive ukuphelisa amabala arhabaxa kunye nemiphetho kwaye ufumane uphawu olugudileyo. Emva kwale nkqubo, ngokuqhelekileyo ibandakanya ukugqiba inkqubela efana nokupeyinta kunye ne-anodizing.

Zeziphi Iindidi Zokwenziwa?

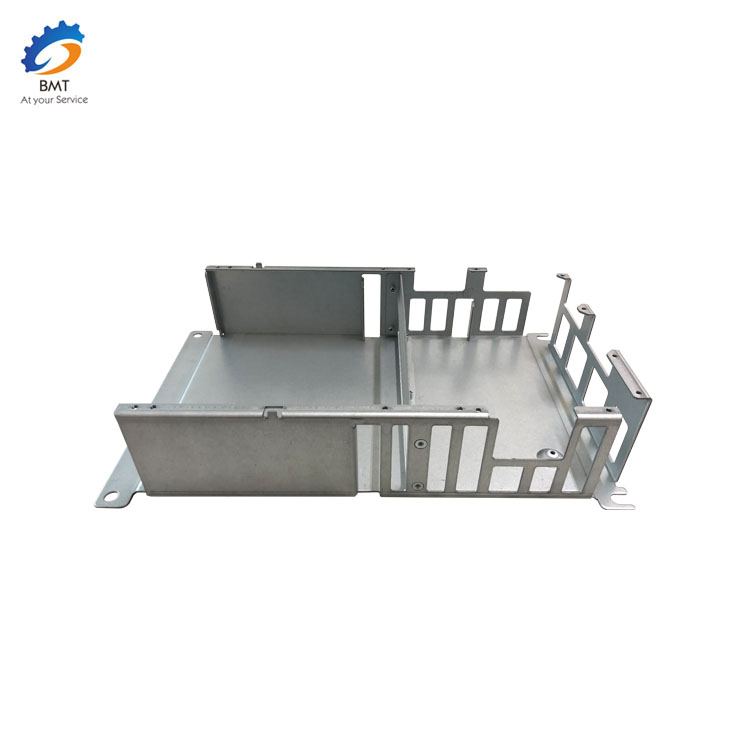

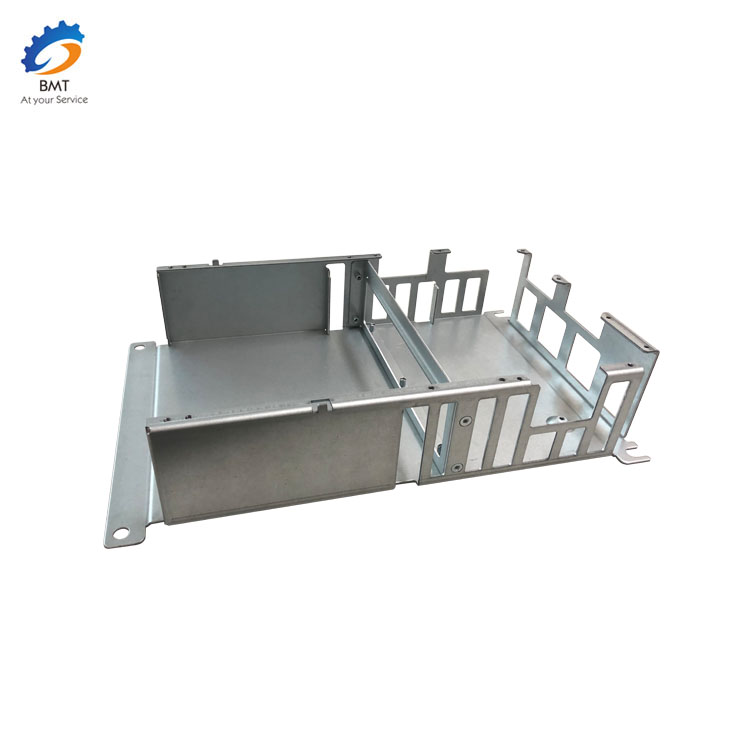

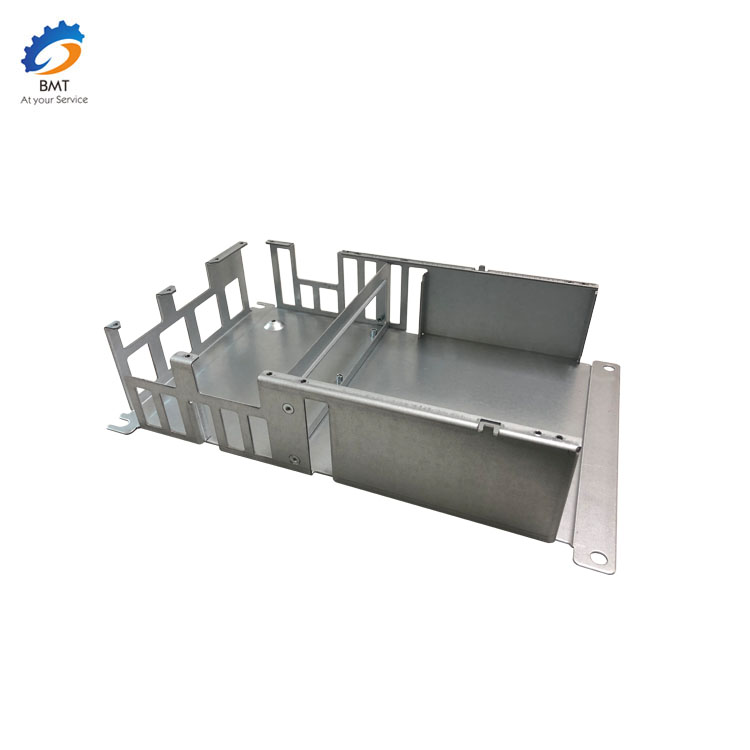

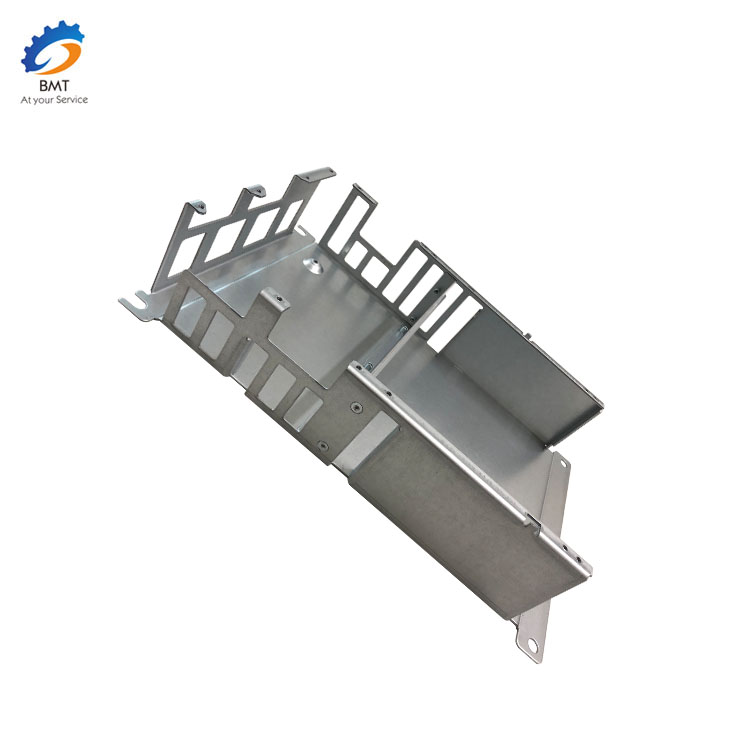

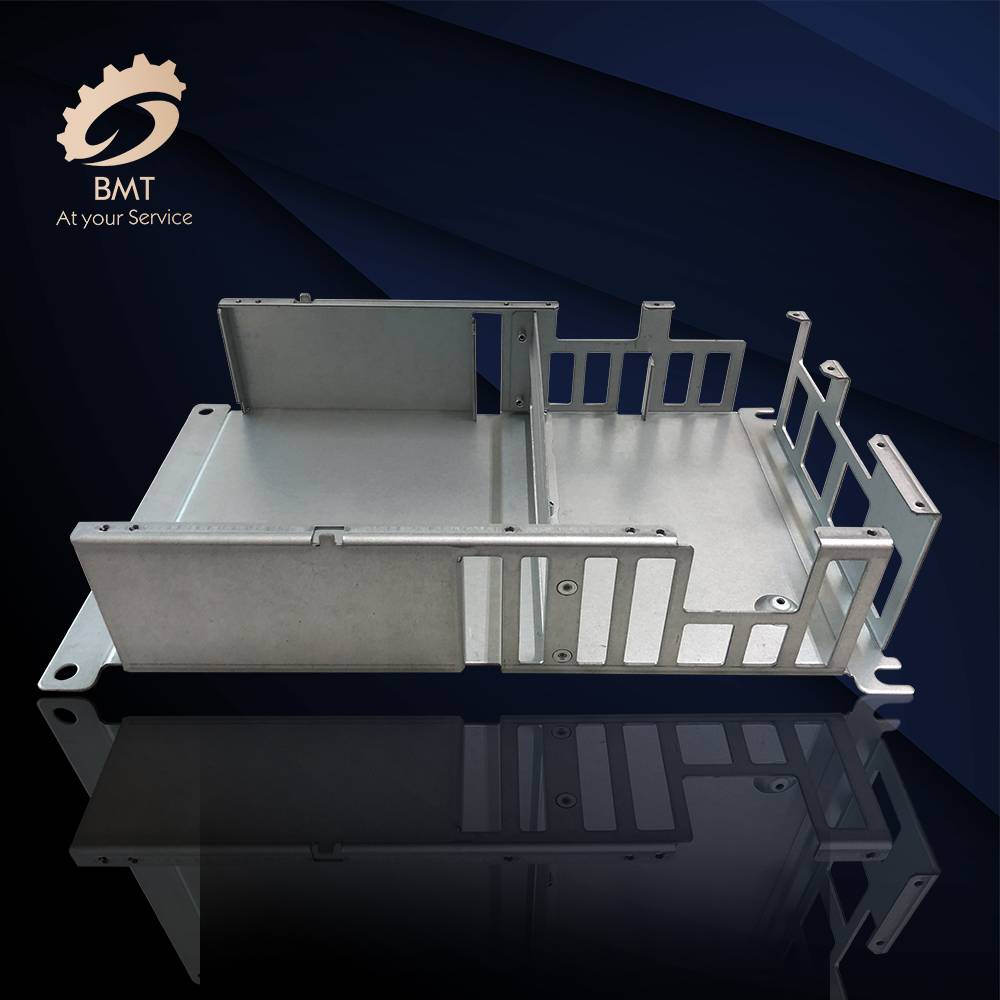

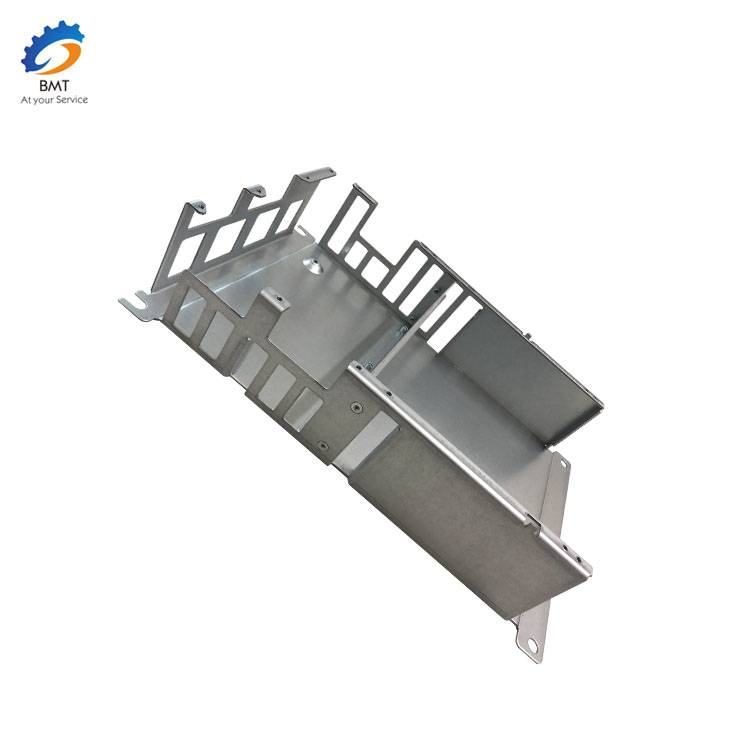

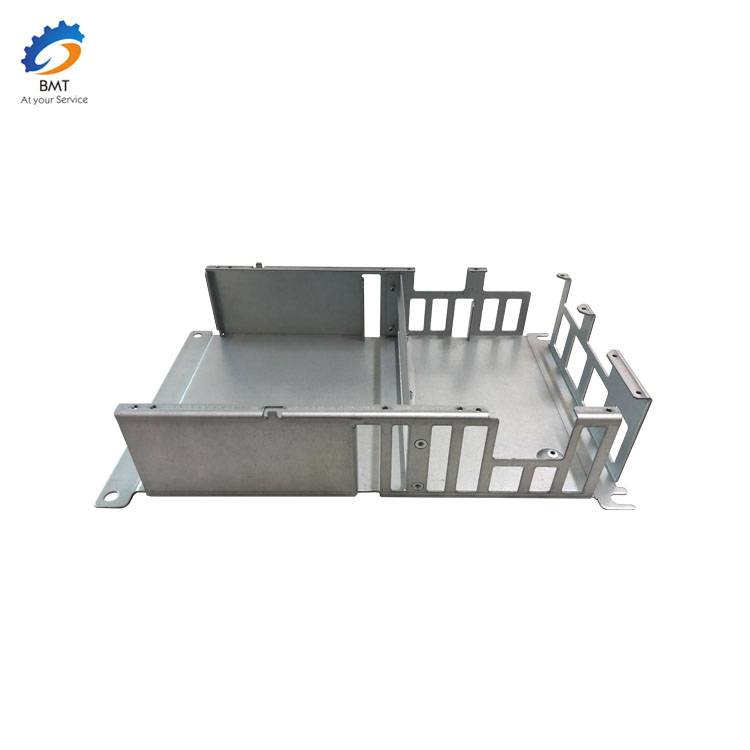

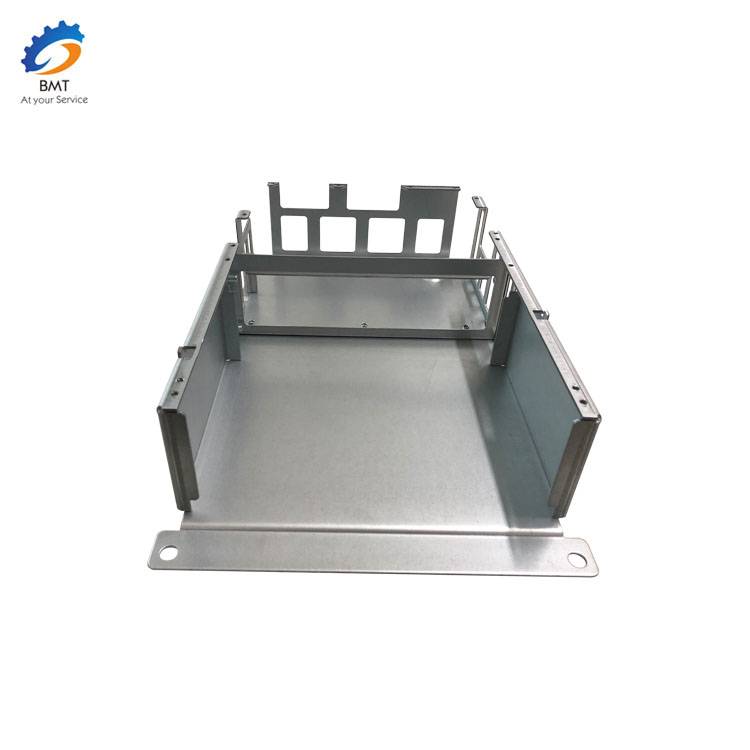

Kukho iintlobo ezininzi zeenkqubo zokwenziwa kwesinyithi. Phakathi kwazo, ezona zixhaphakileyo ziquka Ukusika, ukusonga, ukubumba, ukubethelwa ngenqindi, ukutywina, ukuwelda, nokupholisha. Ukwenza indawo enye, sinokufuna inkqubo enye okanye ezininzi ngasentla ezixhomekeke kuyilo lwenxalenye. Ngokomzekelo, sinokufuna kuphela inkqubo yokusika inxalenye yephepha elinye. Kodwa kusenokufuneka sisebenzise zonke ezi nkqubo zingentla kwimveliso enkulu yekhabhinethi.

Yintoni iPhepha lokutyeba koluhlu lweMetal Fabrication?

Ngaphandle kokuba sidibanisa iziqwenga ezibini zibe sisiqwenga esinye, ubukhulu bemathiriyeli yeshiti kufuneka buhlale buhambelana. Ngaphandle koko, iindidi zesinyithi ziyafumaneka, kwaye ubukhulu beshiti bunokuvela kwi-0.02 intshi ukuya kwi-0.25 intshi.

Ingaba yimalini iPhepha leSiko leMetal Fabrication?

Kuyaxhomekeka. Ixabiso eliqhelekileyo lenxalenye yentsimbi yesiko lixhomekeke kwizinto ezininzi ezibandakanya ubungakanani benxalenye yentsimbi, imathiriyeli, ukuntsonkotha, kunye nobuninzi bokuthenga.

Ngelizwi, ixabiso elincinci lezinto eziphathekayo kunye nexesha elincinci lokuqulunqa ngokusekelwe kwi-MOQ efanayo, ixabiso liphantsi. Ukuze ucombulule iingxaki zakho zokuvelisa, qhagamshelana nathi ngoku kwaye sithatha intlungu kuwe. Sizimisele kwi-CNC Machining kunye neSheet Metal.

Ukwenziwa kwesinyithi seshiti yindlela onokuthi ujike ngayo amacwecwe amacwecwe ensimbi okanye ezinye izinyithi zibe yimveliso okanye uzinike isakhiwo, ngokusika, ukugoba kunye nokudibanisa. Iphepha lesinyithi linokwenziwa malunga naluphi na uhlobo, oluqhelekileyo lwenziwa ngokusika kunye nokugoba isinyithi.

I-Resistance Welding, Ukwandisa i-Metal, ukugoba, i-Laser Cutting, i-Shrinking, i-Tretching, i-punching, i-stamping, njl. Kufuneka uqinisekise ukuba inkampani osebenza nayo inazo ezi zakhono zingentla kwaye ikunike inkonzo engcono ngaphandle kokuthandabuza, nokuba amaxabiso abo aphezulu kancinane, kodwa unokufumana into oyifunayo ngomgangatho ogqibeleleyo kunye neempendulo ezanelisekileyo.

Ingcaciso yeMveliso