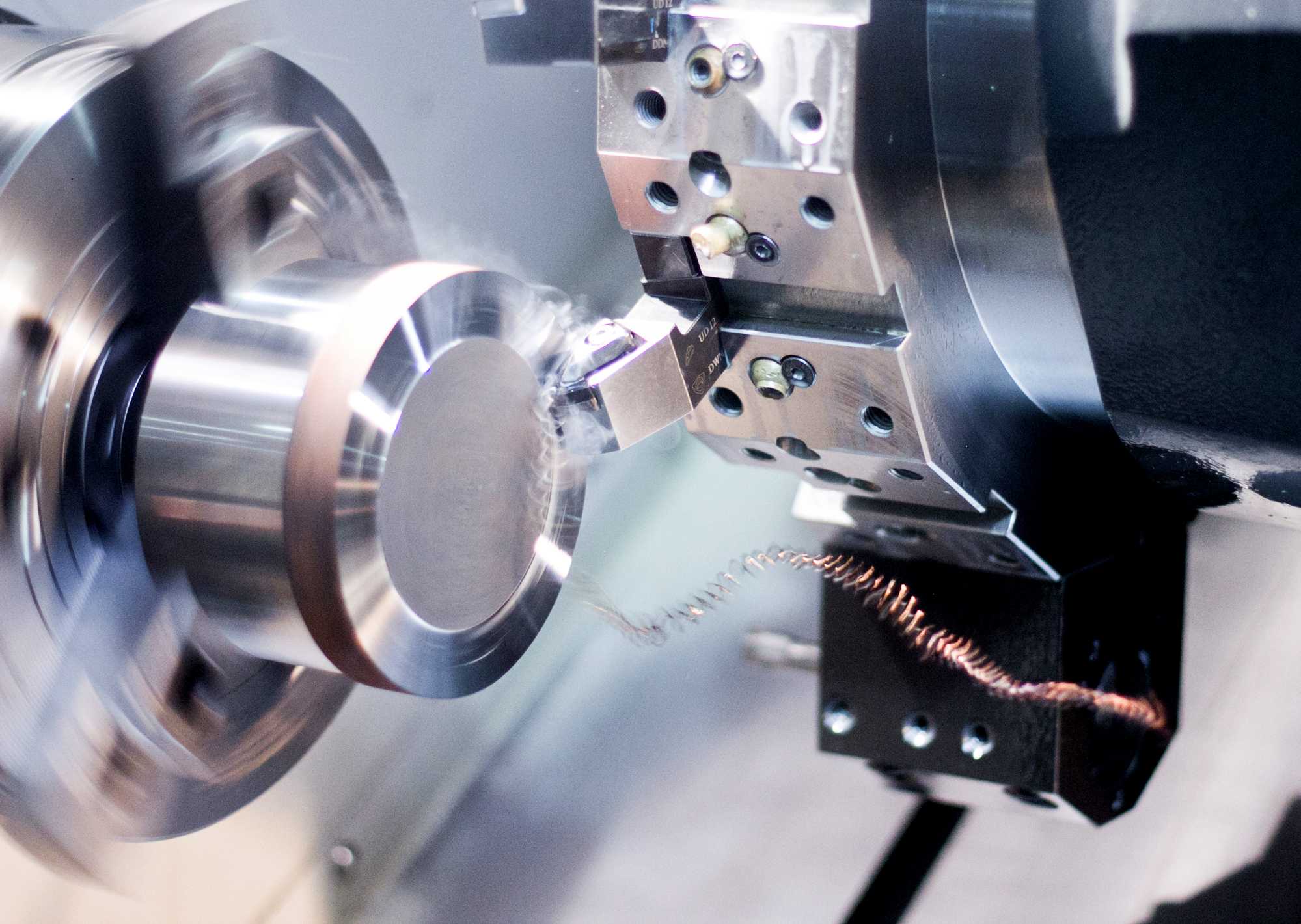

Ehlabathini lokwenziwa kwemveliso, iCNC machining kunye nokwenziwa kwamaphepha entsimbi ziinkqubo ezimbini ezibalulekileyo ezidlala indima ebalulekileyo ekudaleni uluhlu olubanzi lweemveliso. Ukusuka kwizinto ezintsonkothileyo ukuya kwizakhiwo ezinkulu, ezi ndlela zimbini ziphambili kwimveliso yanamhlanje. Makhe sijonge ngakumbi ukubaluleka komatshini we-CNC kunye nokwenziwa kwentsimbi kwishishini. I-CNC (i-Computer Numerical Control) i-machining yinkqubo yokuvelisa esebenzisa ulawulo lwekhompyutheni kunye nezixhobo zoomatshini ukususa izinto ezivela kwi-workpiece. Le ndlela echanekileyo kunye neyobuchule ivumela ukuveliswa kweengxenye ezinzima kunye nokunyamezela okuqinileyo. Nokuba kukusila, ukujika, okanye ukugrumba, iCNC imachining ibonelela ngokuchaneka okungalinganiyo kunye nokuphinda-phinda, oko kuyenza ibe lolona khetho lukhethwayo kumashishini ahlukeneyo, kubandakanya i-aerospace, izithuthi, kunye nezonyango.

Kwelinye icala, ukwenziwa kwamaphepha esinyithi kubandakanya ukwenziwa kwesinyithi ukwenza uluhlu lweemveliso ezahlukeneyo. Ukusuka kwizibiyeli ezilula ukuya kwizibiyeli ezintsonkothileyo, ukwenziwa kwamaphepha entsimbi kubandakanya ukusika, ukugoba, kunye nokudibanisa amaphepha esinyithi ukuhlangabezana neemfuno ezithile zokuyila. Ngenkqubela phambili yetekhnoloji, efana nokusika i-laser kunye ne-CNC punching, ukwenziwa kwamaphepha esinyithi kuye kwaba yinto eguquguqukayo kwaye iyakwazi ukuvelisa uyilo oluntsonkothileyo ngokuchaneka okuphezulu. Xa i-CNC ye-machining kunye ne-sheet metal fabrication idibaniswe, umphumo uyi-synergy enamandla eyenza ukudala imveliso enzima kunye neyomelele. Isakhono somatshini wokwenza izinto ezichanekileyo kwaye emva koko zidibanise kwiindibano zentsimbi yentsimbi iye yaliguqula ishishini lemveliso, nto leyo evumela ukuveliswa kweemveliso eziphucukileyo ezinomgangatho okhethekileyo.

Enye yeenzuzo eziphambili zokusebenzisaCNC Machiningkunye nokwenziwa kwentsimbi yeshiti kunye kukukwazi ukufezekisa ukuhlanganiswa okungenamthungo phakathi kwezinto ezinomatshini kunye namalungu esinyithi. Oku kudityaniswa kubalulekile kumashishini apho ukuchaneka kunye nokuthembeka kwesakhiwo kubaluleke kakhulu, njengokuveliswa kwamalungu eenqwelo-moya, izixhobo zonyango kunye neendawo ezivaliweyo zombane. Ngaphaya koko, indibaniselwano yomatshini we-CNC kunye nokwenziwa kwentsimbi yentsimbi inika abavelisi ukuguquguquka kokusebenza ngoluhlu olubanzi lwezixhobo, kubandakanya i-aluminiyam, insimbi engenasici, kunye ne-titanium. Oku kuguquguquka kuvumela ukudalwa kweemveliso ezingapheliyo kwaye zithembeke kuphela kodwa zikhaphukhaphu kwaye zithandeka ngobuhle.

Ukongeza amandla abo ngabanye, CNC machining kunyesheet metalUkwenziwa kwemveliso nako kunegalelo kwiindlela zokwenziwa kwemveliso ezizinzileyo. Ngokwandisa ukusetyenziswa kwezinto kunye nokunciphisa inkunkuma, ezi nkqubo zihambelana nemigaqo yemveliso eco-friendly. Ngaphaya koko, ukukwazi ukurisayikilisha kunye nokuphinda kusetyenziswe izinto ezilahliweyo zetsimbi kwandisa ngakumbi ukuzinza kokusingqongileyo komatshini we-CNC kunye nokwenziwa kwamaphepha esinyithi. Njengoko itekhnoloji iqhubeka nokuhambela phambili, ukudityaniswa komatshini we-CNC kunye nokwenziwa kwamaphepha entsimbi kulindeleke ukuba kungabinamthungo ngakumbi kwaye kusebenze. Ukusetyenziswa kwesoftware ephucukileyo yoyilo kunye nokulinganisa, kunye nophuhliso lobuchule bokusungula kunye nobuchule bokwenza, kuya kuphucula ngakumbi izakhono zaba babini baguqukayo kwimveliso.

Ukuqukumbela, ukwenziwa komatshini we-CNC kunye neshiti lentsimbi zizinto eziyimfuneko kwimveliso yanamhlanje, enikezela ngokuchaneka, ukuguquguquka, kunye nozinzo. Ukudityaniswa kwezi nkqubo zimbini kutshintshe ukuveliswa koluhlu olubanzi lweemveliso, ukusuka kumacandelo antsonkothileyo ukuya kwizakhiwo ezinkulu. Njengoko ishishini lemveliso liqhubeka nokuvela, intsebenziswano phakathi komatshini we-CNC kunye nokwenziwa kwamaphepha esinyithi ngaphandle kwamathandabuzo kuya kudlala indima ebalulekileyo ekubumbeni ikamva lemveliso.

Ixesha lokuposa: Jul-23-2024