Injani iCNC Machininguya kutshanje?

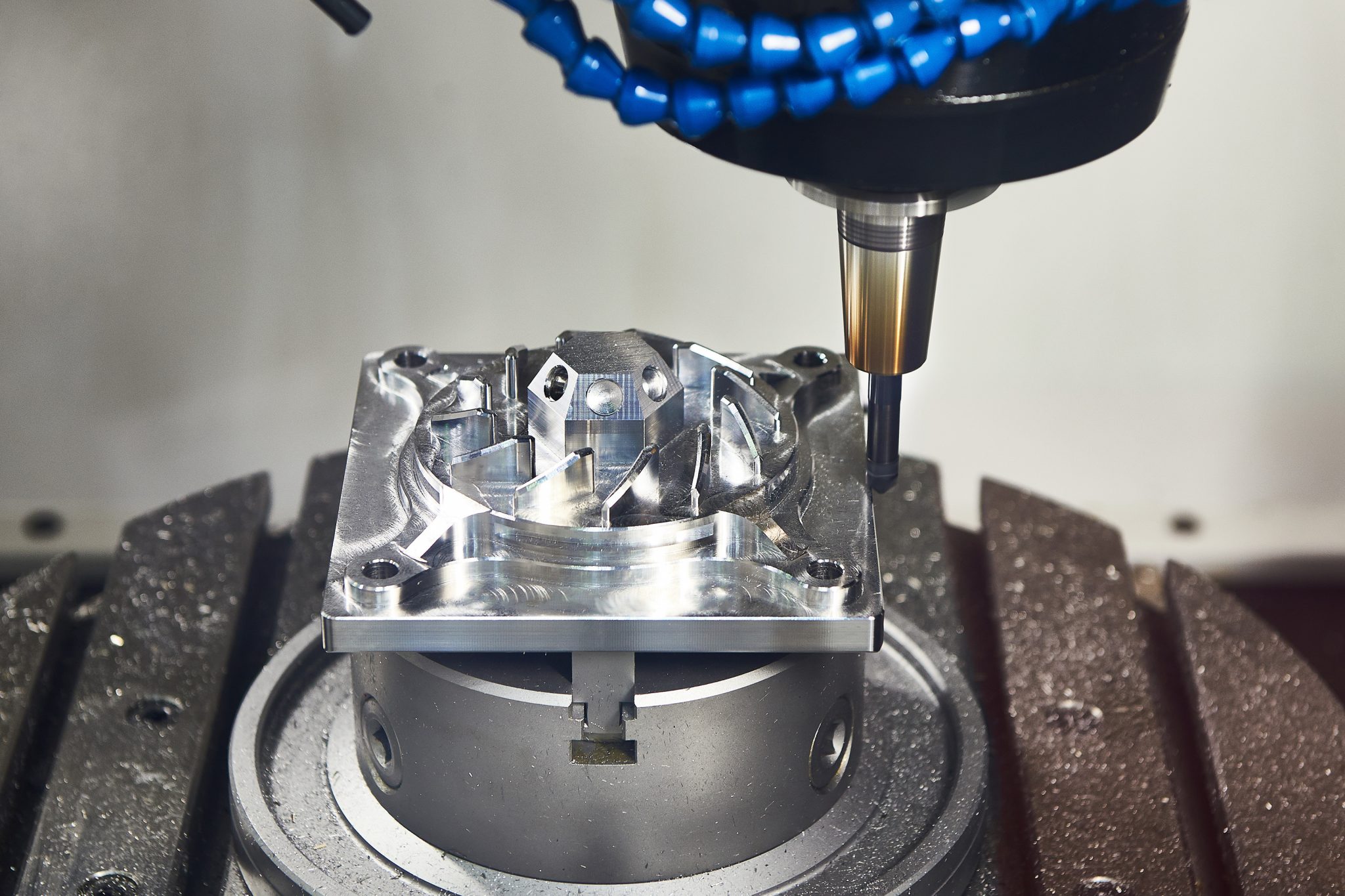

Okwangoku, ekuqhutyweni kweengxenye ezichanekileyo zomatshini, izixhobo zesixhobo ezifanelekileyo zokulungisa insimbi engenasici ziyinsimbi enesantya esiphezulu kunye ne-cemented carbide. Abasiki bentsimbi besantya esiphezulu kulula ukwenza, azibizi, zibukhali, kwaye banobulukhuni obuhle, kodwa abaxhathisi ukunxiba. Inkqubo yokwenziwa kwe-cemented carbide milling cutters iyinkimbinkimbi kwaye ibiza kakhulu, kwaye inokumelana nokunxiba kakuhle phantsi kweemeko zokusika ngesantya esiphezulu, nto leyo eyenza kube lula ukuzinza kokuchaneka kwe-dimensional ye-precision mechanical parts processing.

Ukuthatha i-akhawunti epheleleyo yeempawu ze-CNC machining kunye noqoqosho lwemveliso, le migaqo ilandelayo ingamkelwa: sebenzisa i-high-speed-speed high-speed metal milling cutters ukugqiba, ngenxa yokuba ii-blades ze-high-speed high-speed steel milling cutters zibukhali. I-machining rough ifuna ukuchaneka okuphantsi kokusetha isixhobo, ukusetwa kwesixhobo esilula, ixesha elifutshane elincedisayo, kunye neendleko eziphantsi zokuvelisa. Xa ugqiba, sebenzisa i-carbide end Mills, ekwazi ukusika ngesantya esiphezulu kwaye igcine ukuchaneka komatshini oqhubekayo kunye nozinzile.iindawo zoomatshini ezichanekileyo. Ngaphantsi kweemeko eziqhelekileyo, ukugqitywa kweemveliso ezininzi okanye amakhulu eemveliso zinokugqitywa.

Ukukhethwa kwesixhobo seeparamitha zejometri: Ukukhetha isixhobo kwi-inventri ekhoyo kufuneka kuqwalaselwe iiparamitha zejometri ezifana nenani lamazinyo, i-rake angle kunye ne-blade helix angle. Kwinkqubo yokugqiba, ii-chips zetsimbi ezingenasici azilula ukugoba. Isixhobo esinamazinyo amancinci kunye nepokotho enkulu ye-chip kufuneka ikhethwe ukwenza ukususwa kwe-chip kugudiswe kwaye kunenzuzo ekusetyenzweni kwentsimbi yentsimbi echanekileyo.

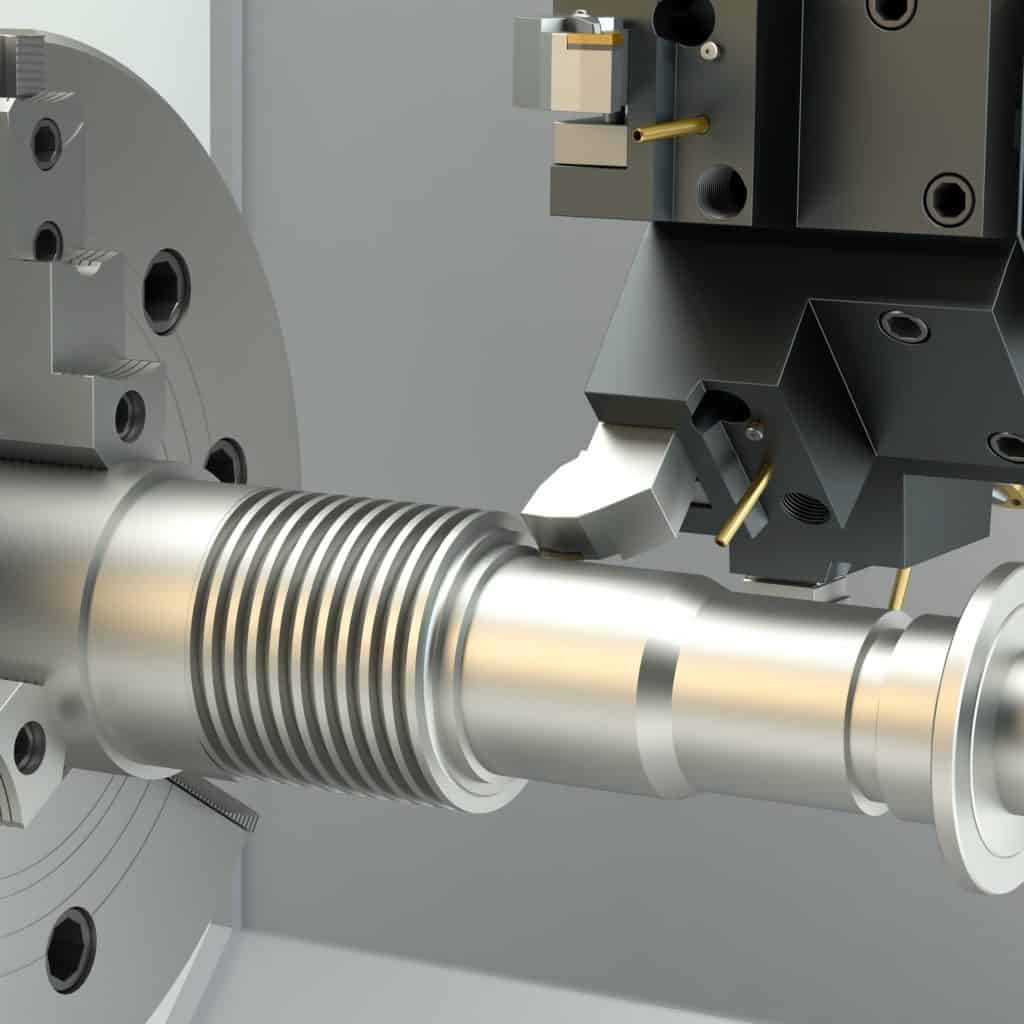

Nangona kunjalo, ukuba i-angle ye-rake inkulu kakhulu, iya kwenza buthathaka amandla kwaye inxibe ukuxhathisa komphetho wokusika isixhobo. Ngokuqhelekileyo, i-end Mill kunye ne-rake angle eqhelekileyo ye-10-20 degrees kufuneka ikhethwe. I-angle ye-helix inxulumene ngokusondeleyo neyona angle ye-rake yesixhobo. Xa kusetyenzwa insimbi engenasici, ukusetyenziswa kwe-helix angle milling cutter kunokwenza amandla okusika abe mancincingokuchanekileyo machininginkqubo kunye nomatshini uzinzile.

Umgangatho womphezulu we-workpiece uphezulu, kwaye i-angle ye-helix ngokubanzi yi-35 ° -45 °. Ngenxa yokusebenza kakubi kokusika, ubushushu obuphezulu bokusika kunye nobomi obufutshane besixhobo sezinto zensimbi ezingenasici. Ke ngoko, ukusetyenziswa kokusikwa kwensimbi engenasici kufuneka kube ngaphantsi kuneyentsimbi yekhabhoni eqhelekileyo.

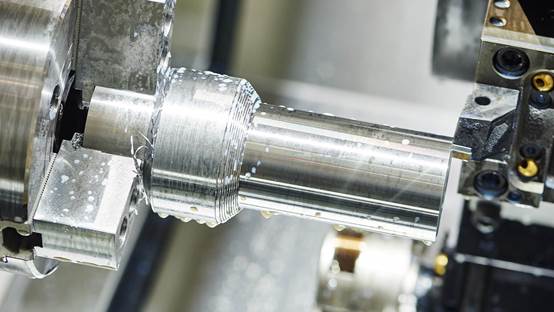

Ukupholisa okwaneleyo kunye nokuthambisa kunokwandisa kakhulu ubomi besixhobo kunye nokuphucula umgangatho womgangatho weendawo ezichanekileyo zoomatshini emva kokucubungula. Kwimveliso yangempela, ioli ekhethekileyo yokusika insimbi engenasici ingakhethwa njengento epholileyo, kwaye umsebenzi wokuphuma kwamanzi kwiziko loxinzelelo oluphezulu lwesixhobo sokuphotha umatshini unokukhethwa. Ioli yokusika ifafazwe kwindawo yokusika kwingcinezelo ephezulu yokupholisa ngenkani kunye ne-lubrication ukuze ifumane ukupholisa kakuhle kunye nefuthe lokuthambisa.

As iinkampani zoomatshini ezichanekileyoukuqhubeka nokuphucula ukuchaneka kwamacandelo kunye namacandelo, i-CNC machining idlala indima ebaluleke kakhulu kuyo yonke inkqubo yokuvelisa, kwaye izixhobo zomatshini ze-CNC ziyathengwa, nto leyo ekhokelela kuluhlu lweengxaki ezifuna ukusonjululwa ngokukhawuleza. . Kwinkqubo yokulungiswa kweengxenye zomatshini ezichanekileyo, izixhobo zokusika, njengesixhobo esibalulekileyo esincedisayo sokuthatha inxaxheba kwimisebenzi yokuvelisa, idlala indima enkulu kwimveliso yezixhobo zomatshini we-CNC kunye nokuchaneka kunye nokuchaneka kokuchaneka kwezinto ezichanekileyo zokucubungula kunye nokuvelisa, ngakumbi ekunyuseni. inani lezixhobo zoomatshini be-CNC. Ukuze ucombulule izinto ezingeloncedo eziziswa kulawulo lokwabela amagunya, ukuphucula ukusebenza kakuhle kokuchaneka kokulungiswa kweengxenye zoomatshini, kunye nokunciphisa iindleko zokusebenza, inani lezixhobo likhulu. Emva koko, izixhobo kufuneka zilawulwe ngendlela esembindini.

Ixesha lokuposa: Mar-15-2021