Kwinkalo yokuvelisa rhoqo,CNC titanium iinxalenye machiningziye zavela njengophawu olutsha lokomelela nokuchaneka. Njengamashishini anje nge-aerospace, iimoto, kunye nezonyango zityhala imida yokuqamba izinto ezintsha, imfuno yezinto ezikumgangatho ophezulu we-titanium iye yanda. Umatshini we-CNC, kunye neepropathi ezikhethekileyo ze-titanium, zibonelela iinjineli ngamathuba angenasiphelo okudala iindawo ezinzima kunye nezomeleleyo. I-Titanium, eyaziwa ngokuba namandla akhethekileyo kumlinganiselo wobunzima, ukuxhathisa ukubola, kunye ne-biocompatibility, iye yaba yinto ekhethwayo kumashishini apho ukuthembeka kunye nokusebenza kubaluleke kakhulu.

Nangona kunjalo,ukwenziwa kwe-titaniumidume ngokuba ngumngeni ngenxa ye-thermal conductivity ephantsi kunye ne-reactivity ephezulu kunye nezixhobo zokusika. Apha kulapho CNC (Computer Numerical Control) machining kungena kudlala. I-CNC machining yinkqubo yokuvelisa elawulwa yikhompyutha evumela ukuveliswa okuchanekileyo kunye nokuphindaphinda kweendawo ezintsonkothileyo. Ngokusebenzisa isoftware ephucukileyo kunye noomatshini abazenzekelayo, umatshini we-CNC ubonelela ngokuchaneka okungenakuthelekiswa nanto kunye nokusebenza kakuhle okugqwesileyo kwiindlela eziqhelekileyo zoomatshini. Idityaniswe ne-titanium, i-CNC machining iququzelela ukuveliswa kwezinto ezinzima, eziphezulu zokusebenza ezihlangabezana neemfuno ezingqongqo kumashishini anamhlanje.

Enye yeenzuzo eziphambili zeCNC titanium iinxalenye machiningsisakhono sokuvelisa iinxalenye zesiko kunye noyilo oluntsonkothileyo kunye neejometri ezintsonkothileyo. Ngetekhnoloji ye-CNC, abavelisi banokujika iimodeli ezintsonkothileyo ze-3D CAD zibe yinyani, benze iinxalenye ezinonyamezelo oluchanekileyo kunye neenkcukacha ezintsonkothileyo. Oku kwenza ukuba iinjineli ziphonononge izinto ezintsha ezinokwenzeka kuyilo lwemveliso kwaye ziphuhlise izisombululo ezibukhali ebekucingwa ukuba azinakufikelelwa. Ukongeza, iinxalenye ze-CNC ze-titanium machining zinika amandla akhethekileyo kunye nokuqina. Umlinganiselo we-Titanium wokomelela kubunzima obuphezulu wenza ukuba ilungele usetyenziso apho ukunciphisa ubunzima kubalulekile ngaphandle kokubeka esichengeni isidima solwakhiwo. Ingaba iinxalenye zayo ze-aerospace ziphantsi kobushushu obugqithisileyo kunye noxinzelelo okanye ukufakelwa kwezonyango ezifuna i-biocompatibility kunye nokuthembeka kwexesha elide, iingxenye ze-CNC ze-titanium machining zinika ukudibanisa okuphumelelayo kwamandla kunye nokusebenza.

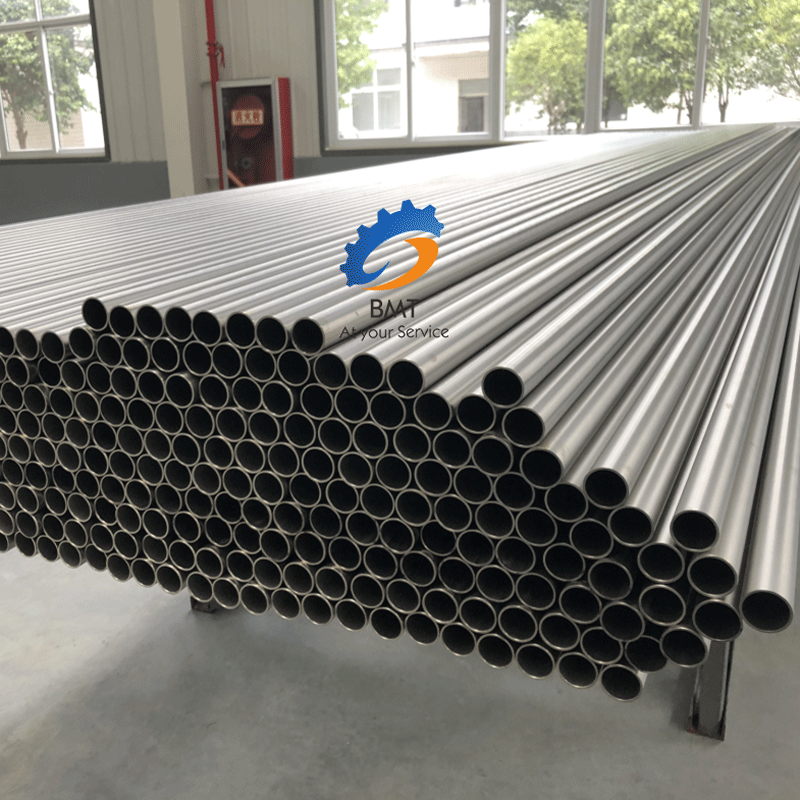

Ngaphezu koko, umatshini weCNC uqinisekisa umgangatho ongaguqukiyo kunye nokuphuculwa kwemveliso. Iindlela zoomatshini eziqhelekileyo zidla ngokutya ixesha, zifuna ukusebenza ngesandla kunye nokutshintshwa rhoqo kwezixhobo. Oomatshini be-CNC, kwelinye icala, banciphisa impazamo yomntu kwaye banciphise ixesha lokuvelisa ngokuvumela ukusebenza ngaxeshanye kwee-axes ezininzi kunye nezixhobo. Oku akwanelisi imveliso kuphela kodwa ikwaqinisekisa umgangatho ongaguqukiyo, njengoko inxalenye nganye yenziwe ngokuchanekileyo kunye nokuphinda-phinda. Ngokunyuka kwemfuno yamacandelo e-titanium, abavelisi batyale imali kwiimatshini zanamhlanje ze-CNC ezenzelwe ngokukodwa ukwenza i-titanium. Aba matshini babonisa izakhiwo ezomeleleyo, iinkqubo zokusonta ezisebenza ngokuphezulu, kunye nobuchule obuphambili bokupholisa ukunciphisa imiceli mngeni eyayanyaniswa nomatshini we-titanium.

Ngokudityaniswa nabaqhubi abanobuchule kunye nolwazi olunzulu lweempawu ze-titanium, abavelisi banokufikelela kwiziphumo ezibalaseleyo ngokwemigangatho yomibini kunye nokusebenza kakuhle. Ukuqukumbela, iinxalenye ze-CNC ze-titanium machining zimele i-epitome yamandla kunye nokuchaneka kwishishini lokuvelisa. Enkosi kubuchwephesha bomatshini be-CNC, iinjineli zinokutyhala imida yoyilo kwaye zenze iindawo ezintsonkothileyo, zesiko ezihlangabezana neemfuno eziqatha kumashishini anamhlanje. Ngeepropathi ezikhethekileyo ze-titanium kunye nokuchaneka kunye nokusebenza kakuhle kwe-CNC, izinto ezinokwenzeka zokusungula izinto ezintsha azipheli. Njengoko imfuno yamacandelo e-titanium ekumgangatho ophezulu iqhubeka nokukhula, ikamva le-CNC titanium machining parts libukeka lithembisa, lithembisa ihlabathi lamandla, ukuthembeka, kunye nokusebenza okungenakulinganiswa.

Ixesha lokuposa: Sep-05-2023