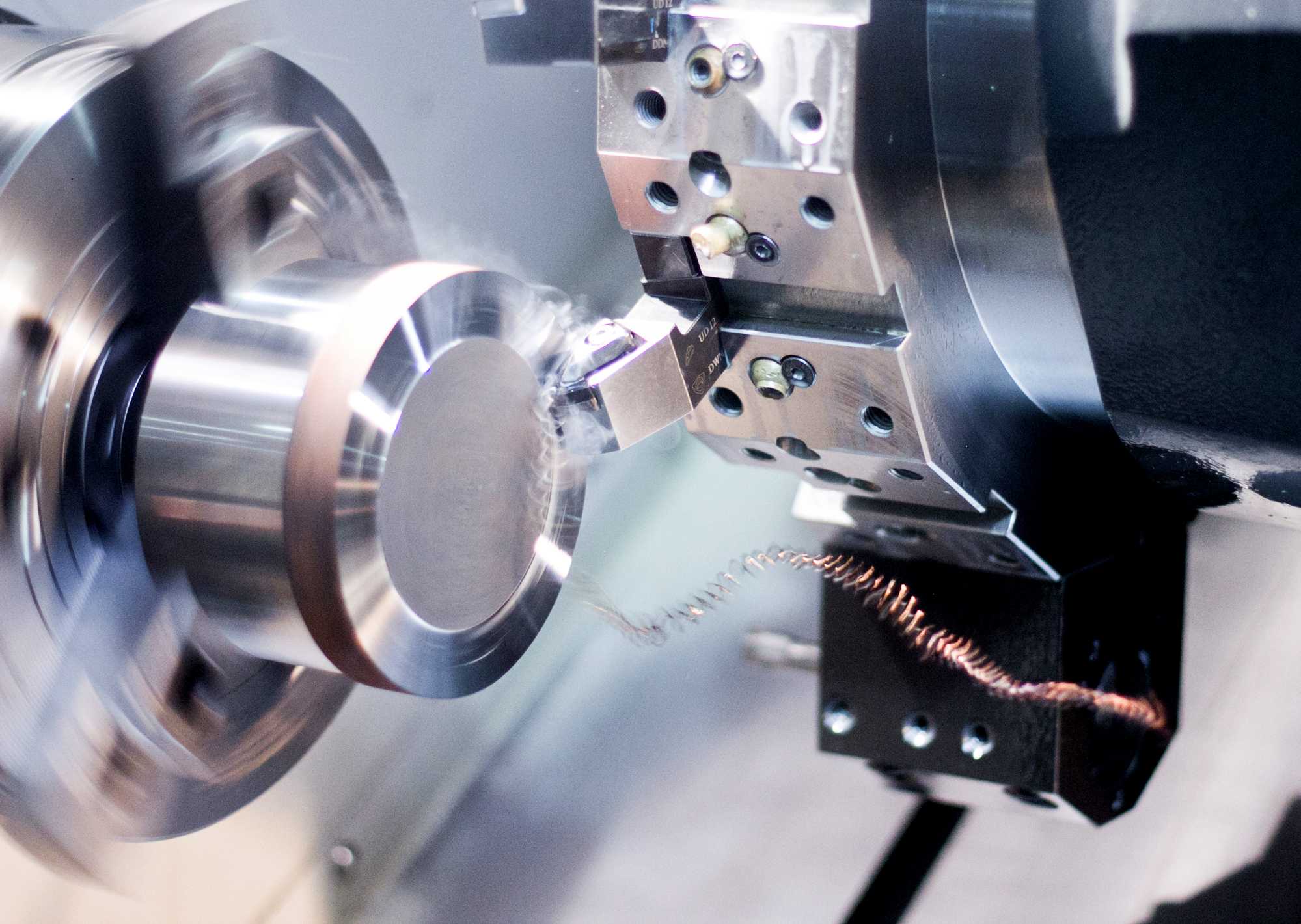

Ukuchaneka komatshini yinkqubo ebalulekileyo kwishishini lokuvelisa, kwaye ukusetyenziswa kwezinto ezahlukeneyo zongeza ubunzima kunye nokwahluka kwimveliso yokuchaneka.iindawo zomatshini. Ukusuka kwisinyithi ukuya kwiiplastiki, uluhlu lwezixhobo ezisetyenziselwa ukuchaneka kwe-machining likhulu, kwaye impahla nganye ibonisa imingeni yayo kunye namathuba abavelisi. Iintsimbi ziqhele ukusetyenziswa kumatshini ochanekileyo ngenxa yamandla azo, ukuqina, kunye nokumelana nobushushu. Intsimbi engatyiwa, ialuminiyam, ititanium, kunye nobhedu yimizekelo nje embalwa yeentsimbi ezihlala zitshintshwa ukuze zenze iindawo ezichanekileyo. Isinyithi ngasinye sidinga ubuchule obuthile bomatshini kunye nezixhobo zokufezekisa ukuchaneka okufunwayo kunye nokugqiba. Umzekelo, insimbi engenasici yaziwa ngokuba lukhuni kunye nokuqina kwayo, ifuna izixhobo ezikhethekileyo zokusika kunye neenkqubo zokupholisa ukuthintela ukushisa nokugcina ukuchaneka ngexesha lomatshini.

Ukwengeza kwiiintsimbi, iiplastikizikwasetyenziswa ngokubanzi kumatshini ochanekileyo. Izinto ezifana nenayiloni, i-polycarbonate, kunye ne-acrylic zibonelela ngeempawu ezizodwa ezifana nokuguquguquka, ukungafihli, kunye nokuxhathisa iikhemikhali, zizenza zilungele uluhlu olubanzi lwezicelo. Iiplastiki zeMachining zifuna uqwalaselo ngononophelo lwemiba efana nokuveliswa kobushushu, ukukhetha izixhobo, kunye nolawulo lwetshiphu ukuphepha ukunyibilika okanye ukugoba izinto. Ngaphaya koko, ukusetyenziswa kwezinto ezidityanisiweyo kumatshini ochanekileyo kufumene ukuthandwa kwiminyaka yakutshanje. Ii-Composites, ezenziwe ngokudibanisa izinto ezimbini okanye ngaphezulu ukwenza izinto ezintsha kunye nezakhiwo eziphuculweyo, zinika enye indlela elula kunye namandla aphezulu kwiintsimbi zendabuko. Ifayibha yeCarbon, i-fiberglass, kunye ne-Kevlar yimizekelo yezinto ezidityanisiweyo ezenzelwe ukuvelisa iindawo ezichanekileyo kumashishini afana ne-aerospace, izithuthi, kunye nezixhobo zemidlalo.

Ukukhethwa kwezinto ezifanelekileyongokuchanekileyo machiningkuxhomekeke kwiimfuno ezithile zenxalenye, kubandakanywa iimpawu zoomatshini, ukuchaneka komgangatho, kunye nokugqitywa komphezulu. Abavelisi kufuneka bavavanye ngononophelo iimpawu zemathiriyeli nganye kwaye balungelelanise iinkqubo zabo zomatshini ukuze bafezekise umphumo oyifunayo. Ukongeza ekukhethweni kwezinto eziphathekayo, ukuchaneka kwe-machining kukwabandakanya ukusetyenziswa kobuchwepheshe obuphezulu obufana nolawulo lwamanani ekhompyutheni (i-CNC), i-multi-axis milling, kunye ne-electrical discharge machining (EDM). Ezi teknoloji zenza ukuba abavelisi bafikelele kumanqanaba aphezulu okuchaneka kunye nokuphindaphinda kwimveliso yamacandelo anzima, kungakhathaliseki ukuba yintoni into eyenziwa ngumatshini.

Imfuno yokuchaneka kweendawo zomatshini ezinezixhobo ezahlukeneyo ziyaqhubeka nokukhula njengoko amashishini efuna ukuphucula ukusebenza kunye nokusebenza kakuhle kweemveliso zawo. Nokuba ivelisa izinto ezintsonkothileyo zezixhobo zonyango okanye isenza iindawo ezomeleleyo zoomatshini bemizi-mveliso, ukukwazi ukwenza umatshini woluhlu olwahlukeneyo lwemathiriyeli ngokuchaneka kubalulekile ukuze kuhlangatyezwane neemfuno eziguquguqukayo zentengiso. Njengoko imbonakalo yomhlaba yemveliso iguquka, uphuhliso lwemathiriyeli emitsha kunye nobuchule bokwenza oomatshini kuya kwandisa ngakumbi amathuba omatshini ochanekileyo. Ukwenziwa kwezinto ezintsha kwimveliso eyongezelelweyo, i-nanomaterials, kunye ne-hybrid machining iinkqubo zilungele ukuguqula indlela echanekileyo yokuveliswa kweengxenye, ukuvula amathuba amatsha kubavelisi ukutyhala imida yento enokwenzeka kwihlabathi lomatshini ochanekileyo.

Ukuqukumbela, iinxalenye zomatshini ezichanekileyo ezinezixhobo ezahlukeneyo yintsimi entsonkothileyo neguqukayo efuna ubuchule, ukusungula izinto ezintsha, kunye nokuguquguquka. Ukukwazi ukusebenza ngezinto ezahlukeneyo, ukusuka kwisinyithi ukuya kwii-composites ukuya kwiiplastiki, kubalulekile ukuba abavelisi bahlangabezane neemfuno ezahlukeneyo zamashishini anamhlanje. Ngokudityaniswa okufanelekileyo kwemathiriyeli, itekhnoloji, kunye nezakhono, ukuchaneka komatshini kuya kuqhubeka nokudlala indima ebalulekileyo ekubumbeni ikamva lemveliso.

Ixesha lokuposa: Aug-12-2024