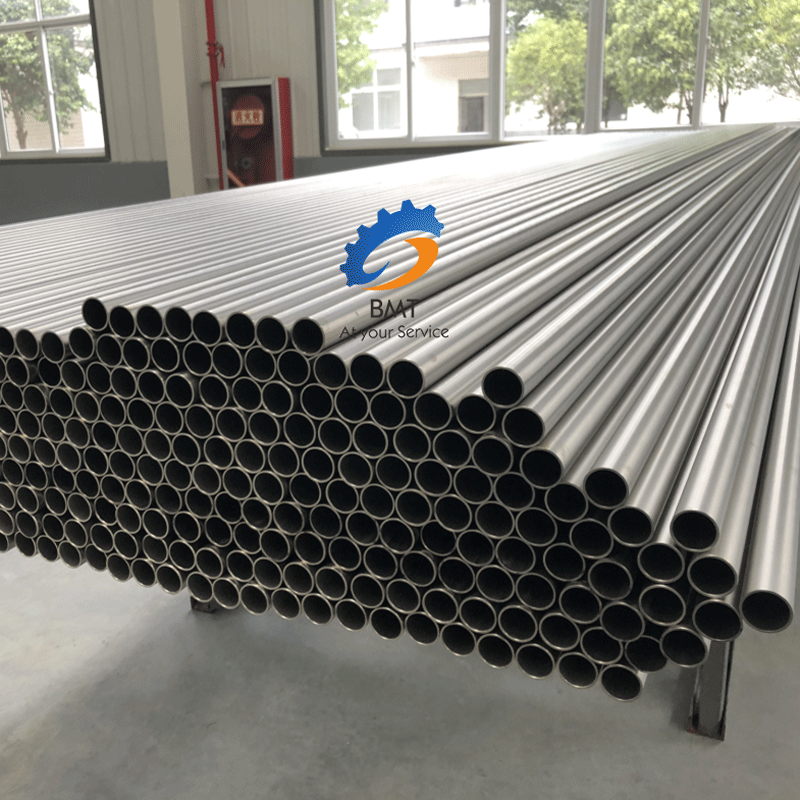

Kuphuhliso olubalulekileyo kwishishini le-metallurgical, ukufakwa kwe-titanium kunyeASTM/ASMEumgangatho wenze uphawu lwabo, ubonelela ngezisombululo zenguqu kumacandelo ngamacandelo. Ukwaziswa kwezi zihlomelo kuzisa inqanaba elitsha lokuqina, amandla, kunye nokuxhathisa umhlwa, okubonelela ngeenzuzo ezinkulu kumashishini afana ne-aerospace, ukusetyenzwa kweekhemikhali, ioli kunye negesi, kunye nokunye. I-Titanium, eyaziwayo ngomlinganiselo wayo ongenakulinganiswa wamandla-to-ubunzima, sele iyinto efunwayo kumashishini afuna ukusebenza okuphezulu phantsi kweemeko ezinzima. Ngokudityaniswa kwe-ASTM/ASME izifakelo ezisemgangathweni, amandla e-titanium afikelele kubude obutsha.

Olu fakelo luthobela umgangatho ongqongqo kunye neendlela zokusebenza ezisekwe nguMbutho waseMelika woVavanyo kunye neMpahla (ASTM) kunyeUmbutho waseMelika weeNjineli zoomatshini (ASME), ukuqinisekisa ukuthembeka okukhethekileyo kunye nokuhambelana. Enye yeenzuzo eziphambili zokufakelwa kwe-titanium kunye nomgangatho we-ASTM/ASME kukwazi ukumelana nobushushu obugqithisileyo kunye noxinzelelo. Oku kubenza balungele ukusetyenziswa kwi-oyile kunye ne-gas industry, apho banokuthi bavezwe kwiimeko ezinzima, uxinzelelo oluphezulu, kunye nolwelo olonakalisayo. Ukuphunyezwa kwezi zifakelo kunciphisa kakhulu iindleko zokulondolozwa kunye nokwandisa ukhuseleko olupheleleyo lwemisebenzi.

Ngaphezu koko, ishishini le-aerospace nalo liye lamkelaizixhobo ze-titaniumnjengomtshintshi womdlalo. Ngeempawu zayo ezikhaphukhaphu kunye namandla aphezulu, i-titanium ifanelekile ngokufanelekileyo kwizakhiwo zenqwelomoya. Ngokusebenzisa i-ASTM/ASME ukufakwa kwemigangatho, imboni ngoku inokufezekisa umgangatho ophezulu, ukuchaneka, kunye nokusebenza kumacandelo eenqwelo-moya, ukuqinisekisa ukuba iinqwelomoya ezikhuselekileyo nezisebenzayo. Umzi-mveliso wokulungiswa kweekhemikhali, osebenza ngolwelo olunokutya okuninzi, uzuza kakhulu ekuxhathiseni ukubola kwezifakelo ze-titanium. Izinto zemveli zihlala zinikezela kuhlaselo lwekhemikhali, nto leyo ekhokelela ekutshintshweni rhoqo kunye nexesha lokuphumla. Nangona kunjalo, ukuphunyezwa kwe-ASTM / ASME imilinganiselo ye-titanium esemgangathweni ibonelela ngesisombululo esomeleleyo, ukunciphisa iinzame zokugcina kunye nokwandisa imveliso.

Esinye isicelo esiphawulekayo sokufakelwa kwe-titanium kwintsimi yezonyango. Ubume be-Titanium obungeyotyhefu kunye nokuhambelana nebhayoloji kuyenza ibe lolona khetho lufanelekileyo lofakelo lwezonyango, olufana namalungu okwenziwa, ukufakelwa kwamazinyo, kunye nezixhobo zentliziyo. Ngokuqinisekiswa okongeziweyo kwemigangatho ye-ASTM / ASME, uluntu lwezonyango lunokuthembela ekuthembekeni nasekukhuseleni ukufakwa kwe-titanium, ukuphucula kakhulu iziphumo zesigulane. Ngaphaya koko, ukwaziswa kokufakwa kwetitanium ngomgangatho we-ASTM/ASME kuvula amathuba amatsha kwiiprojekthi ezahlukeneyo zokwakha. Ukusuka kwiibhulorho kunye namabala emidlalo ukuya kwimimangaliso yezakhiwo, ukufakwa kwe-titanium kunika ukuguquguquka okukhulu koyilo kunye nobomi obude xa kuthelekiswa nezinto eziqhelekileyo. Ukuxhathisa kwabo ekudlekeni, kwimozulu, kunye nokunxitywa kuqinisekisa ukuba izakhiwo zihlala zomelele kwaye zithandeka ngobuhle kwiminyaka ezayo.

Nangona kunjalo, kubalulekile ukuqaphela ukuba ngaphandle kweenzuzo eziphawulekayo zokufakelwa kwe-titanium kunye nomgangatho we-ASTM / ASME, ixabiso labo lihlala liphezulu kunokufakelwa kwendabuko. Iinkqubo ezikhethekileyo zokuvelisa kunye namanyathelo angqongqo olawulo lomgangatho anegalelo ekwenyukeni kweendleko. Nangona kunjalo, iingenelo zexesha elide kunye nokuqina okuziswa yi-titanium fittings kumashishini ukodlula utyalo-mali lokuqala.

Ukuqukumbela, ukufika kokufakwa kwe-titanium kunye nomgangatho we-ASTM/ASME kuphawula inqanaba elibalulekileyo kwishishini lesinyithi. Ezi zifakelo zinika amandla akhethekileyo, ukuxhathisa umhlwa, kunye nokuqina, kubenza baxabiseke kumacandelo ohlukeneyo. Ukusuka kwi-aerospace ukuya kwezonyango, i-oyile kunye negesi ukuya kulwakhiwo, usetyenziso olubanzi kunye nezibonelelo zokufakelwa kwe-titanium ziqinisekisa ikamva eliqaqambileyo nelihambele phambili ngakumbi kumashishini kwihlabathi liphela.

Ixesha lokuposa: Jul-10-2023