I-Titaniumsisixhobo esifunwa kakhulu kumashishini ahlukeneyo ngenxa yamandla aso angaqhelekanga, ukumelana nomhlwa, kunye neempawu ezikhaphukhaphu. Iqhele ukusetyenziswa kwi-aerospace, ezonyango, kunye nezicelo zeemoto, phakathi kwabanye. Xa kuziwa ekubumbeni i-titanium kwizinto ezithile, iindlela ezimbini eziphambili zihlala zisetyenziswa: ukubumba kunye nokuphosa. Indlela nganye inesethi yayo yezinto eziluncedo kunye nezithintelo, ikwenza kubaluleke kakhulu ukuba abavelisi bawuqonde umahluko phakathi kwezi nkqubo zimbini.

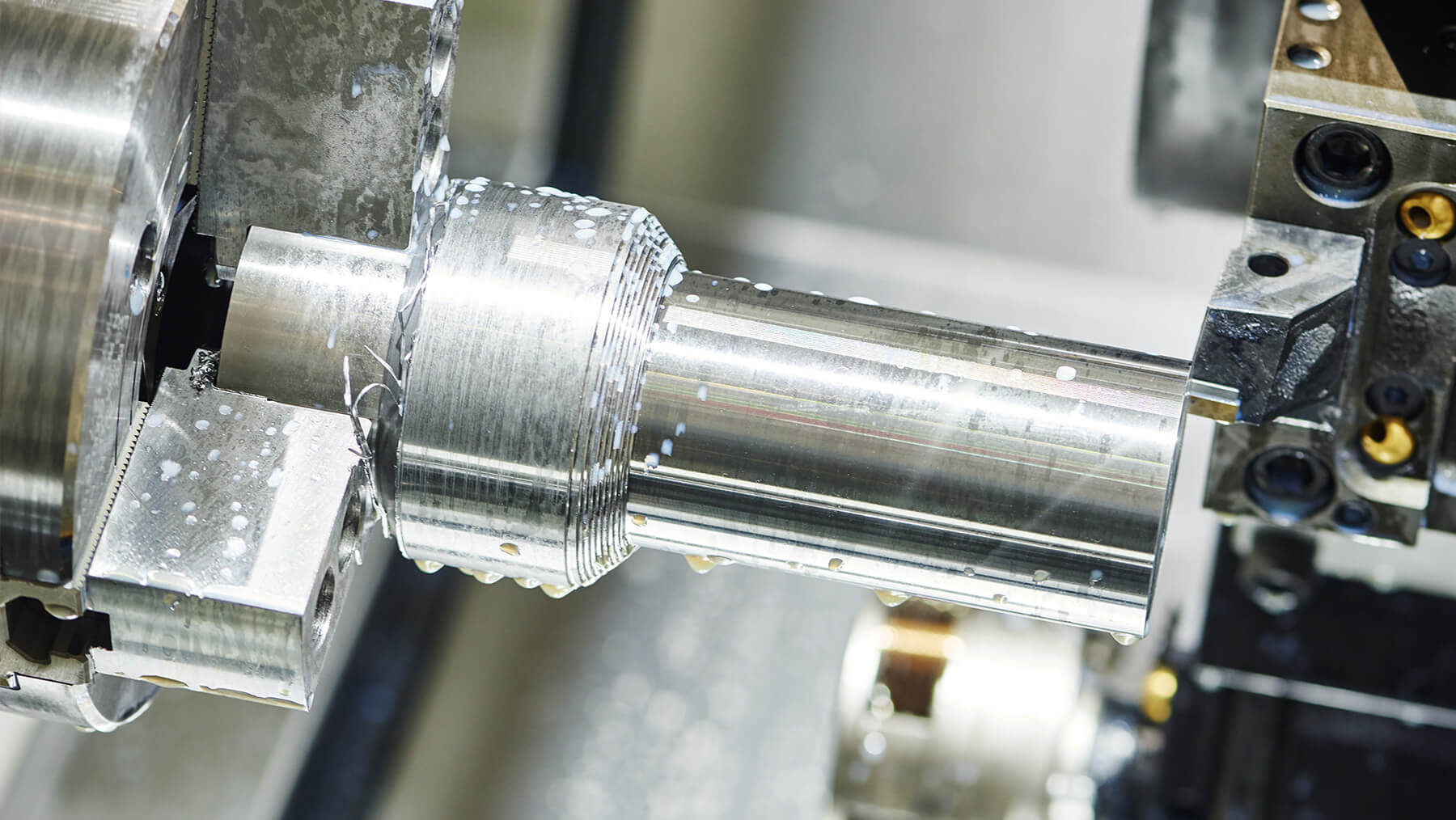

I-Forging yinkqubo yokuvelisa ebandakanya ukubunjwa kwesinyithi ngokusebenzisa ukusetyenziswa kwamandla oxinzelelo. Kwimeko ye-titanium,ukwenzaiqhele ukwenziwa kumaqondo obushushu aphezulu ukunyusa iplastiki yemathiriyeli kunye nokuququzelela inkqubo yokuguqulwa. Isiphumo siyinxalenye eneempawu eziphuculweyo zoomatshini, njengamandla aphezulu kunye nokumelana nokudinwa okungcono. Ukongeza, iindawo ezibunjiweyo ze-titanium zihlala zibonisa ubume bengqolowa obugqwesileyo, obunegalelo kwiimpawu zabo zokusebenza eziphezulu. Kwelinye icala, ukugalela yinkqubo ebandakanya ukugalela isinyithi esinyibilikisiweyo kwisingundo kunye nokusivumela ukuba siqine sibe kwimilo oyifunayo. Ngelixa ukujula kuyindlela eneendleko ezithe kratya ekuveliseni iijiyometri ezintsonkothileyo kunye namalungu amakhulu, kusenokungasoloko kunika inqanaba elifanayo leepropathi zoomatshini kunye nentembeko yolwakhiwo njengamalungu enziweyo e-titanium. Amacandelo e-titanium ye-Cast anokuba nesakhiwo senkozo erhabaxa kunye ne-porosity ephezulu, enokuthi ichaphazele ukusebenza kwayo jikelele kunye nokuthembeka.

Omnye umahluko ophambili phakathi kokwenza kunyeukuphosa i-titaniumilele kwi-microstructure yezinto. Xa i-titanium yenziwe, inkqubo ilungelelanisa ulwakhiwo lweenkozo zesinyithi ukulandela imilo yecandelo, okukhokelela kwi-microstructure efanayo kunye nesulungekileyo. Olu lungelelwaniso luphucula iimpawu zoomatshini kwaye lwenza ukuba luxhathise ngakumbi ukudinwa kunye nokusasazwa kwee-crack. Ngokwahlukileyo, iindawo ezisamente zetitanium zinokubonisa ubume benkozo obufanayo obunganeno, obunokuthi bukhokhelele kukwahluka kweempawu zoomatshini kunye nokubeka esichengeni ingqibelelo yecandelo. Olunye uqwalaselo olubalulekileyo linqanaba lenkunkuma yezinto ehambelana nenkqubo nganye.

Ukubumba ngokubanzi kuvelisa inkunkuma yezinto ezincinci xa kuthelekiswa nokuphosa, njengoko kubandakanya ukubumba i-titanium kwifomu efunwayo ngokuguqulwa okulawulwayo kunokunyibilika kunye nokuqinisa isinyithi. Oku kunokwenza ukubumba kube yinto ezinzileyo nengabizi kakhulu, ngakumbi kwizinto ezinexabiso eliphezulu njenge-titanium. Ngaphaya koko, iimpawu zoomatshini zei-titanium eyenziweAmalungu asoloko eqikeleleka ngakumbi kwaye ayangqinelana kunalawo amacandelo okujula. Oku kuqikelelwa kwangaphambili kubalulekile kumashishini apho ukuthembeka kwecandelo kunye nokusebenza kubaluleke kakhulu, njenge-aerospace kunye nokusetyenziswa kwezonyango. Ngokulawula iiparitha zenkqubo yokubumba, abavelisi banokulungelelanisa iipropathi zomatshini zamacandelo e-titanium ukuhlangabezana neemfuno ezithile, ukuqinisekisa umgangatho ophezulu womgangatho kunye nokuthembeka.

Ukuqukumbela, zombini ukwenza kunye nokuphosa ziindlela ezisebenzayo zokubumba i-titanium kumacandelo ahlukeneyo, ngalinye linesethi yalo yeenzuzo kunye nemida. Ngelixa ukuphosa kunokulungela ngakumbi ukuvelisa iijiyometri ezintsonkothileyo kunye neendawo ezinkulu ngexabiso eliphantsi, ukubunjwa kunika ulawulo oluphezulu kwi-microstructure yemathiriyeli kunye neempawu zoomatshini, okukhokelela kumacandelo anamandla aphezulu, ukumelana nokudinwa okungcono, kunye nokuthembeka okuphuculweyo. Ekugqibeleni, ukhetho phakathi kokwenza kunye nokuphosa i-titanium kuxhomekeke kwiimfuno ezithile zesicelo kunye nebhalansi efunekayo phakathi kweendleko, ukusebenza kunye nokuzinza.

Ixesha lokuposa: Apr-22-2024