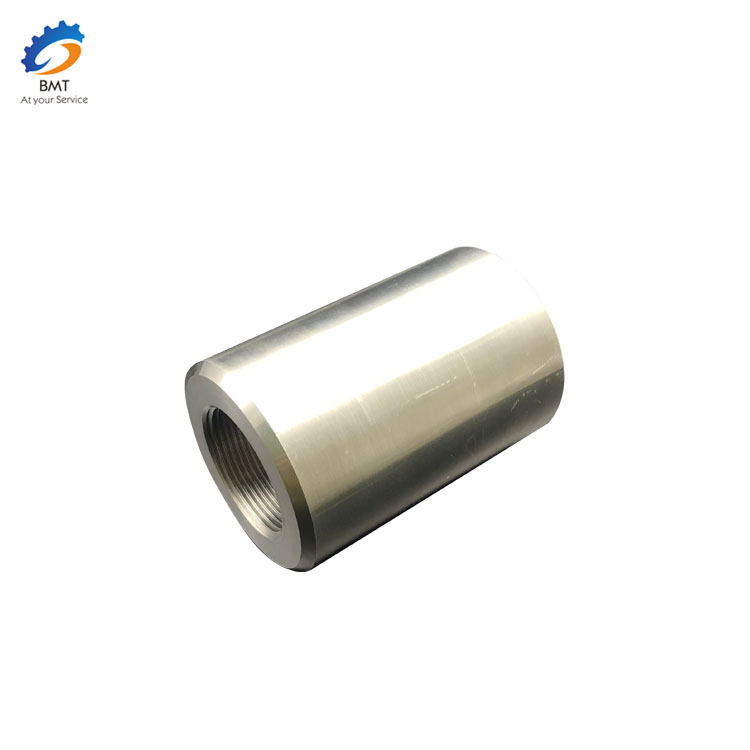

OEM Machining Service evela BMT

Amanyathelo okuseka iUmatshiniInkqubo yeNkqubo

1) Bala inkqubo yemveliso yonyaka kwaye unqume uhlobo lwemveliso.

2) Hlalutya umzobo wenxalenye kunye nomzobo wendibano yemveliso, kunye nohlalutyo lwenkqubo yamacandelo.

3) Khetha izikhewu.

4) Yenza indlela yenkqubo.

5) Qinisekisa isibonelelo somatshini wenkqubo nganye, ubale ubungakanani benkqubo kunye nokunyamezela.

6) Ukumisela izixhobo kunye nezixhobo, izixhobo, izixhobo zokulinganisa kunye nezixhobo ezincedisayo ezisetyenziswa kwinkqubo nganye.

I-7) Ukumisela i-dosage yokusika kunye ne-quota yexesha.

8) Ukugqiba iimfuno zobugcisa kunye neendlela zokuhlola inkqubo nganye ephambili.

9) Gcwalisa amaxwebhu enkqubo.

Kwinkqubo yokwenza iinkqubo zobuchwepheshe, kudla ngokuyimfuneko ukulungelelanisa umxholo oye wagqitywa ngaphambili, ukwenzela ukuba kuphuculwe inzuzo yezoqoqosho. Kwinkqubo yokuphunyezwa kweenkqubo zenkqubo, kunokubakho imeko engalindelekanga, njengokutshintsha kweemeko zemveliso, ukuqaliswa kobuchwepheshe obutsha, iteknoloji entsha, ukusetyenziswa kwezinto ezintsha, izixhobo eziphambili, njl., zonke zifuna ukuhlaziywa kwangexesha kwaye ukuphuculwa kweenkqubo zenkqubo.

Impazamo yokutshixa ibhekisa kwiqondo lokutenxa phakathi kweeparameters zejometri (ubungakanani bejometri, imilo yejometri kunye nesikhundla sokubambisana) kunye neeparamitha ezifanelekileyo zejometri emva komatshini. Emva komatshini, iqondo lokuhambelana phakathi kweeparitha zejometri zangempela kunye neeparitha ezifanelekileyo zejometri kukuchaneka komatshini. Incinci impazamo yomatshini, kokukhona inqanaba lokuhambelana liphezulu, kokukhona kuphezulu ukuchaneka komatshini. Ukuchaneka komatshini kunye nempazamo yomatshini ziindlela ezimbini zengxaki efanayo. Ngoko ke, ubungakanani bempazamo yokucubungula bubonisa ukuchaneka kokulungiswa.

1. Imposiso yokwenziwa komatshini wokwenziwa komatshini wesixhobo sokwenza impazamo ikakhulu ibandakanya impazamo yokujikeleziswa kwe-spindle, impazamo yesikhokelo sikaloliwe kunye nempazamo yekhonkco lokuhambisa. Impazamo yokujikelezisa i-spindle ibhekisa kwi-axis yokujikeleza yokwenyani yomzuzu ngamnye ngokunxulumene ne-avareji yomjikelezo we-axis yotshintsho, iya kuchaphazela ngokuthe ngqo ukuchaneka kwe-workpiece ecutshungulwayo. Ezona zizathu ziphambili zempazamo yokujikeleza kokusonta yimpazamo ye-coaxiality ye-spindle, impazamo yokuthwala ngokwayo, impazamo ye-coaxiality phakathi kweebheringi, ukujikajika kokusonta, njl. njl. inxalenye yesixhobo somatshini kwisixhobo somatshini, ikwayidatha yentshukumo yesixhobo somatshini. Impazamo yokuvelisa, ukuguga okungalinganiyo kunye nomgangatho wofakelo lwesikhokelo sikaloliwe zizinto ezibalulekileyo ezibangela impazamo yesiporo sesikhokelo. Impazamo yesixokelelwano sothumelo ibhekisa kwimpazamo yentshukumo ehambelanayo phakathi kwezinto zothumelo kuzo zombini iziphelo zekhonkco lothumelo. Ibangelwa yimpazamo yokuvelisa kunye nendibano yekhonkco yecandelo ngalinye kwikhonkco lokuhambisa, kunye nokuguga kwinkqubo yokusetyenziswa.

2. Iphutha lejometri yesixhobo nasiphi na isixhobo kwinkqubo yokusika ayinakuphepheka ukuvelisa ukunxiba, kwaye ngaloo ndlela kubangele ukuba ubungakanani kunye nemilo ye-workpiece itshintshe. Impembelelo yempazamo yejiyometri yesixhobo kwimpazamo yomatshini iyahluka kunye neentlobo ezahlukeneyo zezixhobo: xa usebenzisa izixhobo zokusika ubungakanani obusisigxina, impazamo yokuvelisa isixhobo iya kuchaphazela ngokuthe ngqo ukuchaneka komatshini womsebenzi; Nangona kunjalo, kwisixhobo esiqhelekileyo (njengesixhobo sokuguqula), impazamo yokuvelisa ayinayo impembelelo ngqo kwimpazamo yomatshini.