Iindlela ezi-5 zokuphucula iiNdawo zeMetal Sheet

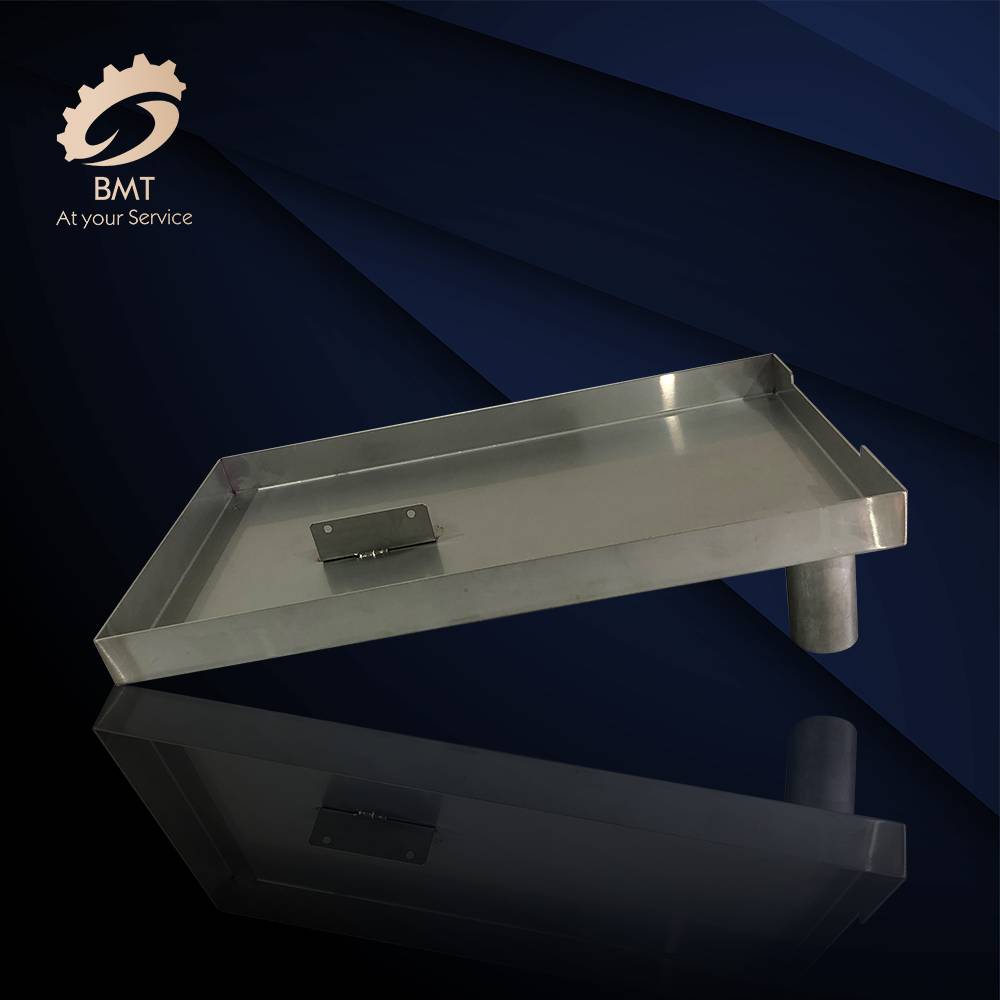

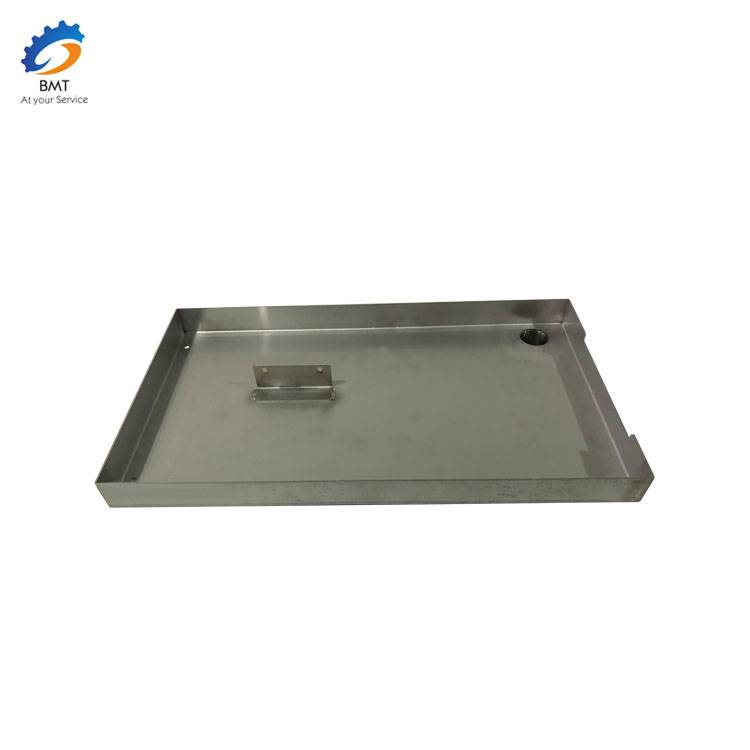

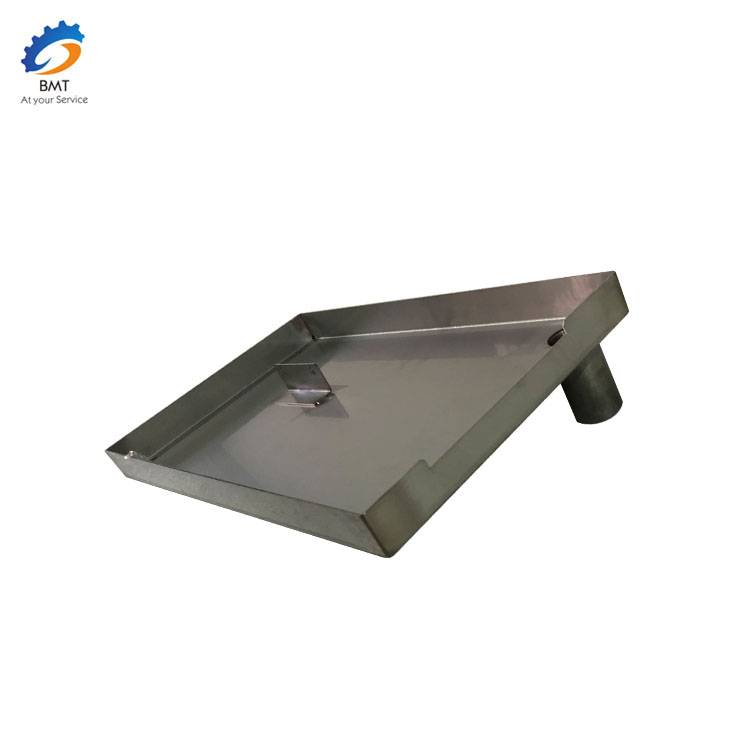

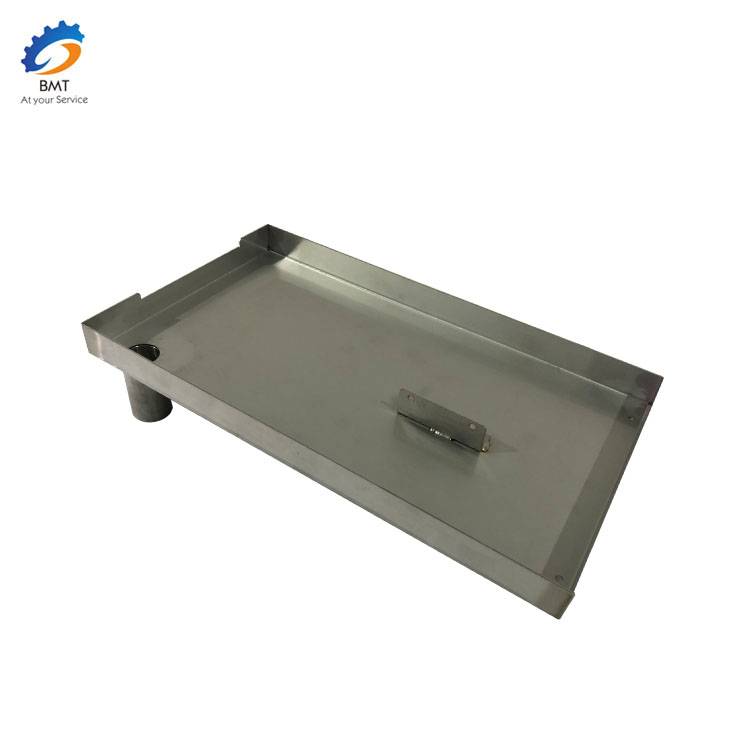

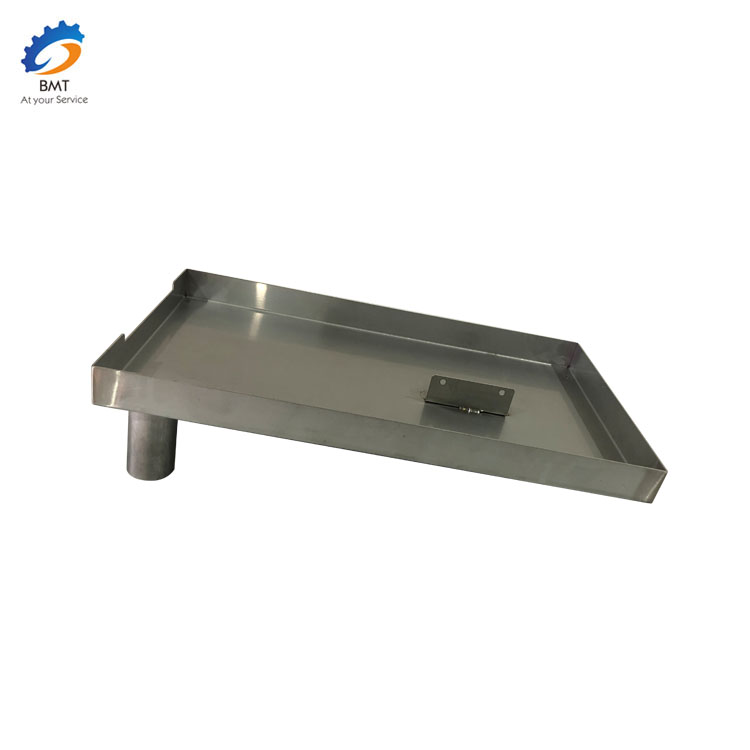

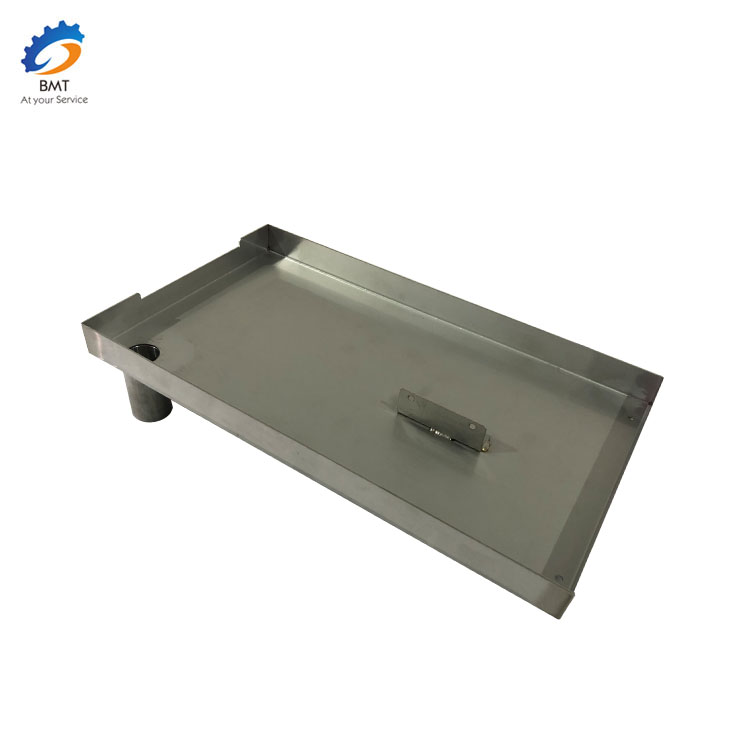

Ukwenziwa kwesinyithi seshiti yiseti esebenzayo yeenkqubo zokuvelisa ezisetyenziselwa ukwenza iinxalenye ezivela kwiziqwenga ezisicaba zentsimbi.Icwecwe lesinyithi liza kuluhlu lwezixhobo kunye nobukhulu, kwaye linokusetyenziswa ukwenza iindawo ezinjengezixhobo zombane, izivalo, izibiyeli, iiphaneli kunye netshisi, njl.

Xa kuthelekiswa nomatshini we-CNC, ukwenziwa kwamaphepha esinyithi kumiselwa ziinkcukacha zoyilo ezingqongqo.Kubasebenzi abathile abatsha kwi-sheet metal fabrication, mhlawumbi kunzima.Icwecwe lesinyithi kufuneka ligobe kwaye lisikwe ngeendlela ezithile, kwaye lilungele kuphela iindawo ezithile kunye neemveliso.

Ngokwenyani, kubalulekile ukufunda imigaqo esisiseko yokwenziwa kwamaphepha esinyithi ngaphambi kokuba usebenze.Ukusebenzisa i-sheet metal fabrication, iichwephesha zinokwenza iindawo ezihlala zihlala, eziphantsi kweendleko ezivela kwizinto ezahlukeneyo.Ezi ndawo zinokusetyenziswa kuluhlu olubanzi lwemizi-mveliso, ukusuka kwi-aerospace ukuya kwisixhobo sasekhaya.

Ubukhulu beshiti lesinyithi elisetyenziswe kwinkqubo yokuvelisa ngokuqhelekileyo phakathi kwe-0.006 kunye ne-0.25 ", kunye nemilinganiselo exhomekeke kwizinto ezinikeziweyo kunye nokusetyenziswa kokuphela kwenxalenye.

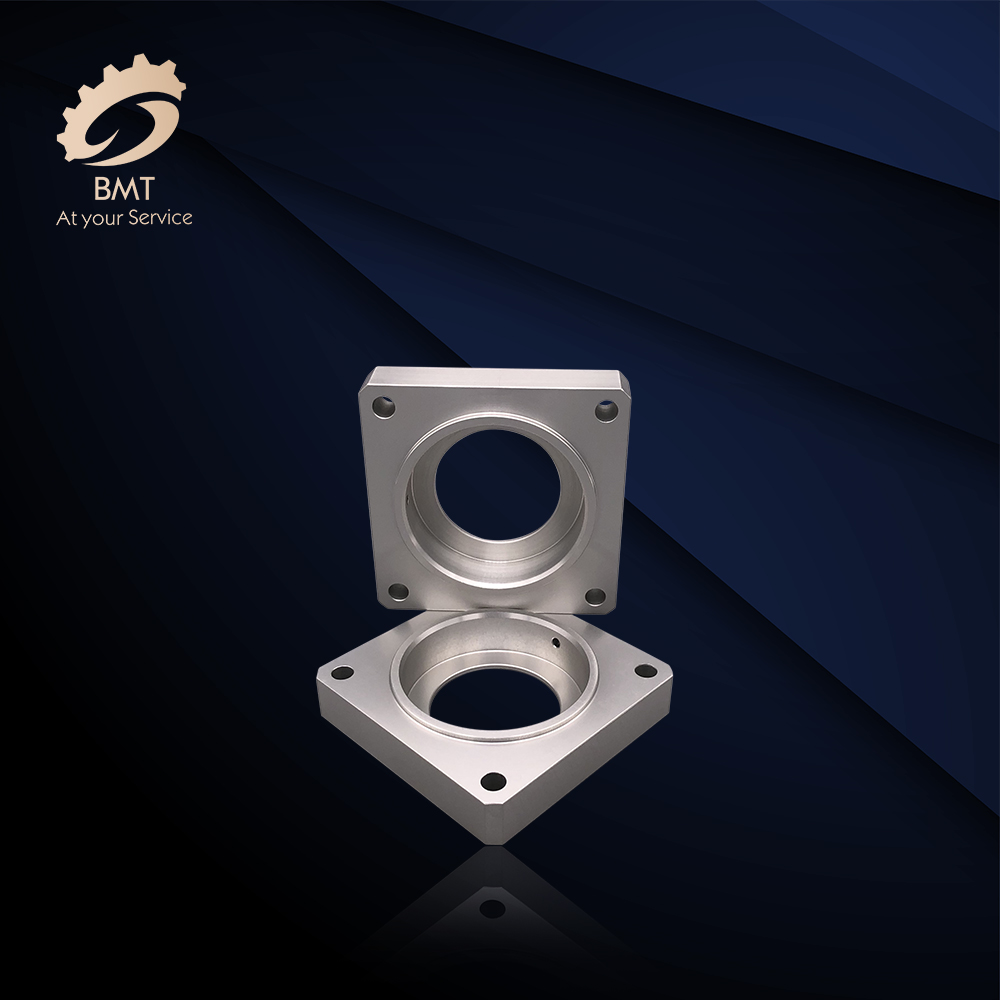

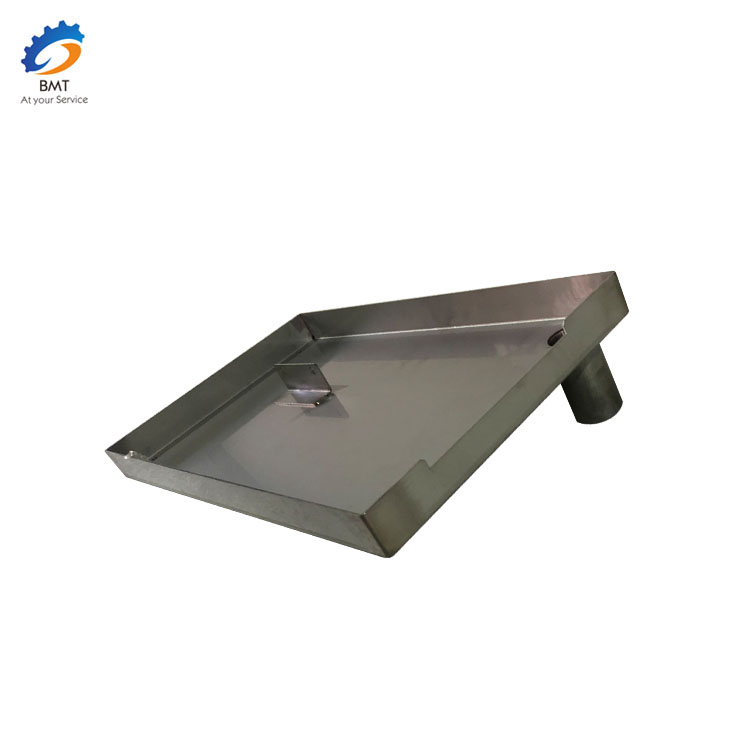

Ingcaciso yeMveliso

Ukwenziwa kwesinyithi seshiti kukhethekile phakathi kweenkqubo ezahlukeneyo zokuvelisa.Ngesi sizathu, ubuchwephesha bunokuthi buyilwe iinxalenye zobuchwephesha be-CNC okanye iindawo zokubumba, kodwa kunzima ukuyila iinxalenye zentsimbi.

Ngokuqwalasela ezi ngcebiso zintandathu zilandelayo, abaqulunqi banokwenza iinxalenye zentsimbi ezomeleleyo, ezilula ukwenza kwaye zixhathisa ukuphuka.

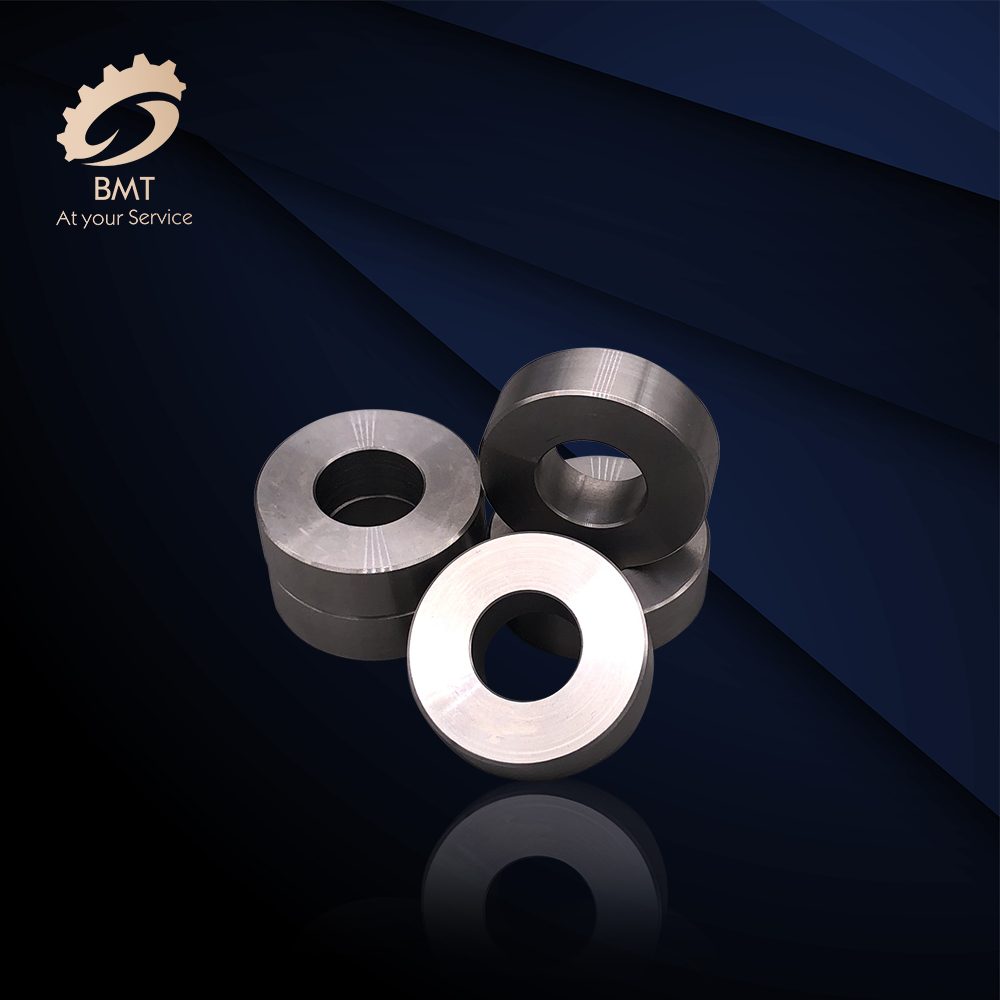

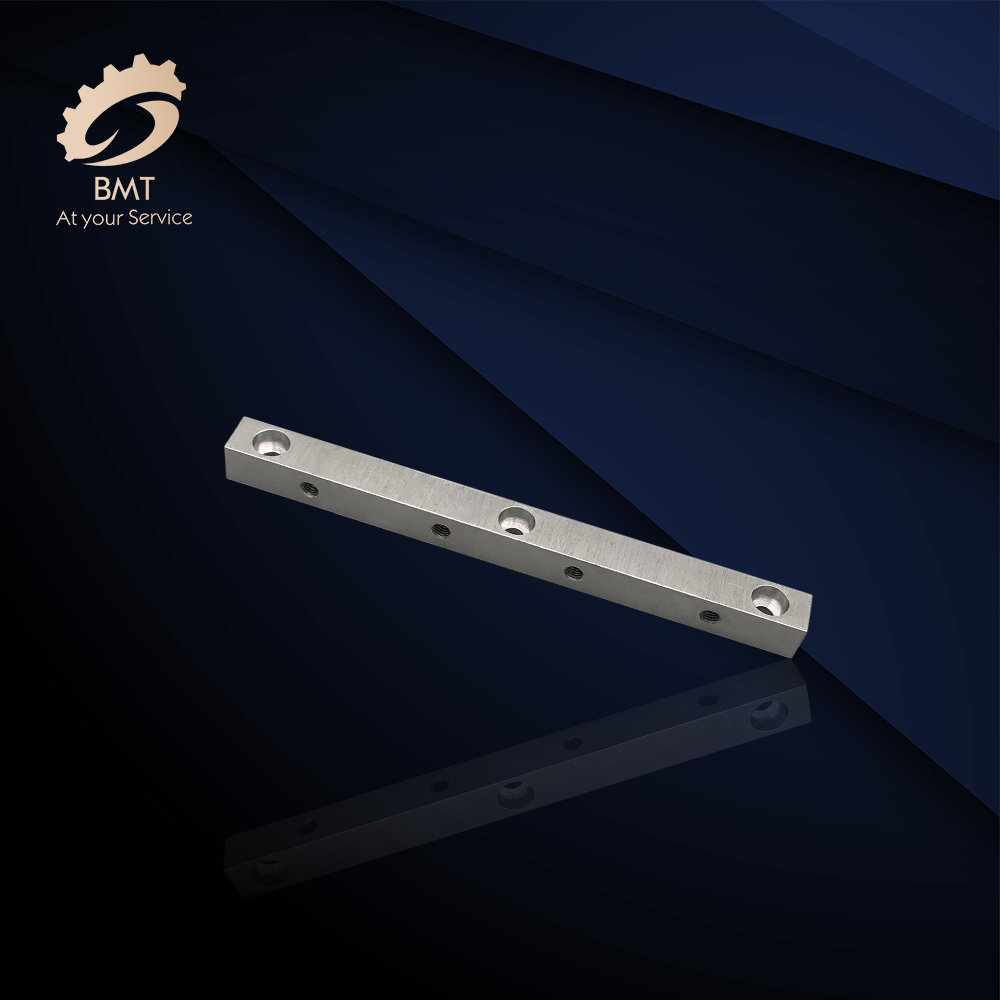

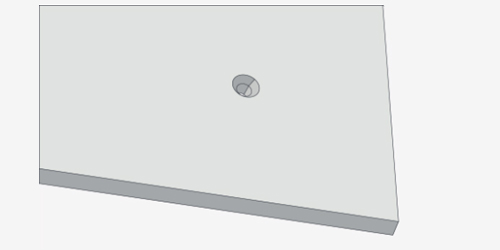

1. Imingxuma kunye Slots

Ekubeni i-sheet metal fabrication isetyenziselwa rhoqo ukudala i-enclosures, i-brackets kunye nezinto ezifanayo, imingxuma kunye ne-slots zivame ukufunwa kwi-screws, i-bolts okanye amacandelo adibeneyo.Imingxunya idla ngokudalwa nge-punch kwaye ifa ifakwe kwi-press, evumela ukuba imilo echanekileyo yesetyhula inqunywe kwiphepha lesinyithi.Kodwa ukuba imingxunya ayenziwanga kakuhle, loo mngxuma usenokukhubaza okanye ude ubangele ukuba inxalenye ngokwayo yaphuke.

Xa ubhobhoza imingxuma kwiphepha lesinyithi, imigaqo embalwa ebalulekileyo kufuneka ilandelwe.Imingxuma kufuneka ibe yi-1/8” kulo naluphi na udonga okanye udini kwaye kufuneka ihlukaniswe ngokuphindwe kayi-6 ubukhulu beshiti lesinyithi.Ngaphezu koko, i-diameters yazo zonke imingxuma kunye ne-slots kufuneka ihambelane okanye idlule ubukhulu be-sheet metal.

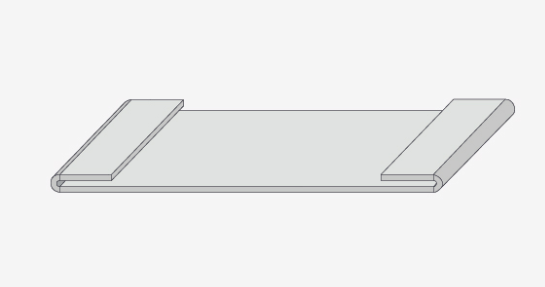

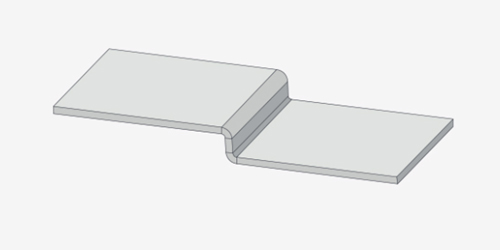

2. IiHems

I-Hemming yindlela efanelekileyo yokwenza i-sheet metal part ikhuselekile kwaye isebenze.Senza zombini iihem ezivulekileyo nezivaliweyo.Ukunyamezela komphetho kuxhomekeke kwiradiyasi yomqukumbelo, ubukhulu bezinto eziphathekayo, kunye neempawu ezikufutshane nomphetho.Sincoma ukuba ubuncinci bedayamitha yangaphakathi bulingane nobukhulu bezinto eziphathekayo, kunye nobude bokubuyisela umphetho we-6x ubukhulu bezinto.

Xa ufaka i-hem kwi-sheet metal part, izikhokelo ezimbalwa kufuneka zilandelwe ukuqinisekisa ukusebenza kakuhle.Kwabaqalayo, phantse kusoloko kungcono ukuphepha iihem ezivaliweyo.I-hems evaliweyo ibeka ingozi yokonakalisa izinto ngenxa ye-angle egqithisileyo ye-bend, ngoko ke ii-hems ezivulekileyo, ezishiya i-gap phakathi kwamacala amabini e-hem, zikhethwa.

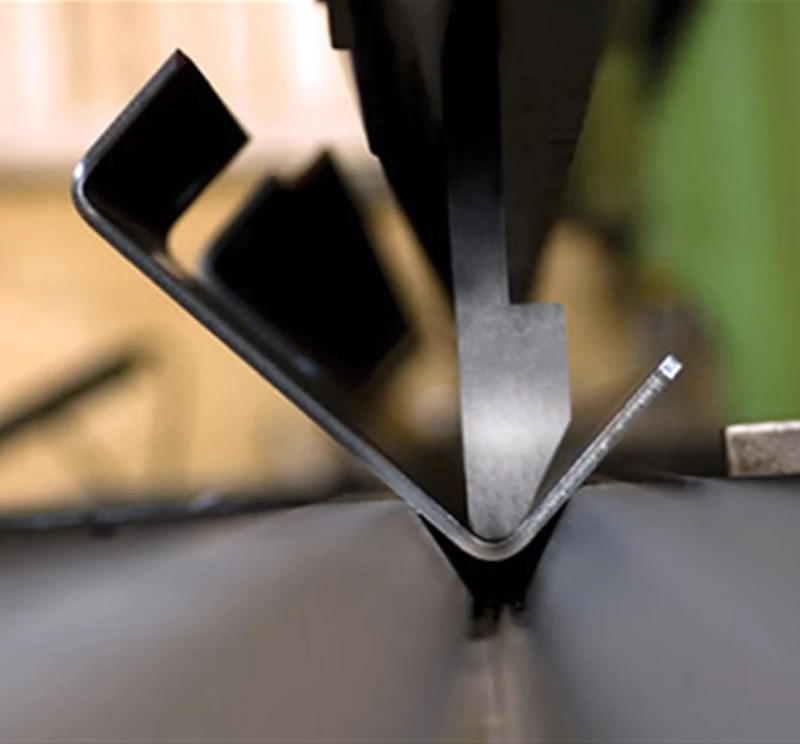

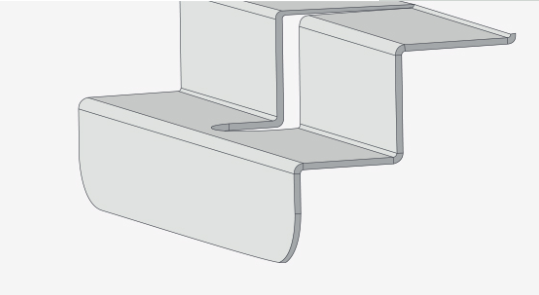

3. Ukugoba

Ukugoba yenye yezona nkqubo zibalulekileyo zokwenza i-sheet metal fabrication.Usebenzisa izixhobo ezifana neziqhoboshi kunye noomatshini bokushicilela, umzi-mveliso uyakwazi ukusebenzisa isinyithi samaphepha sibe ziimo ezintsha.Ukugoba, ukwenzela ukuba kuqinisekiswe ukuchaneka kunye nokugoba, kufuneka silandele imithetho ethile, kwaye sinciphise ukuba nokwenzeka komonakalo kwizinto eziphathekayo.

Umgaqo omnye omele ulandelwe kukuba, xa uyila inxalenye yeshidi yentsimbi kunye nokugoba, i-radius ye-bend yangaphakathi kufuneka ihambelane okanye idlule ubukhulu bephepha lesinyithi ukuphepha ukuguqulwa.Kucetyiswa ukuba usebenzise iradiyasi efanayo kuwo onke amagophe.Ukugcina ukuhambelana kwi-bend direction kunye ne-radius kunokunceda ukunciphisa iindleko, njengoko inxalenye ayiyi kufuneka ihlaziywe kwaye izixhobo zokugoba zingaphinda inkqubo enye efanayo.

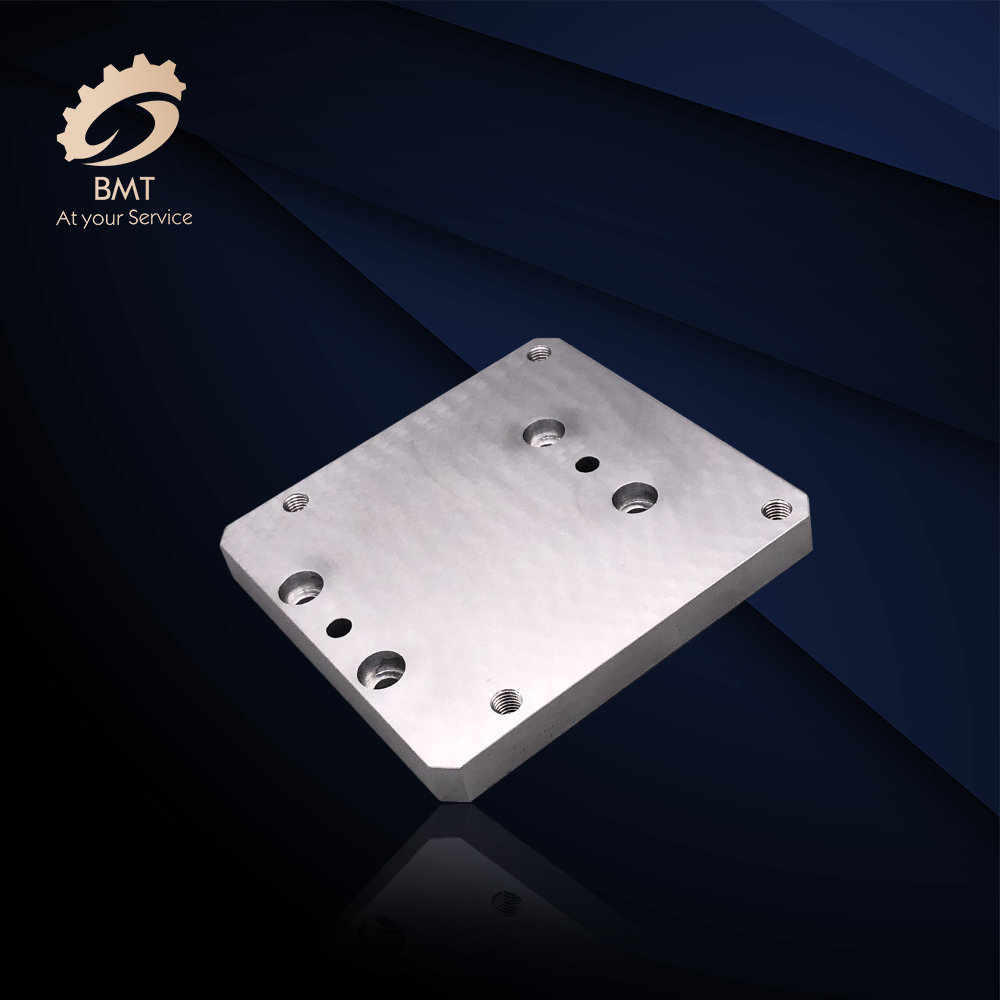

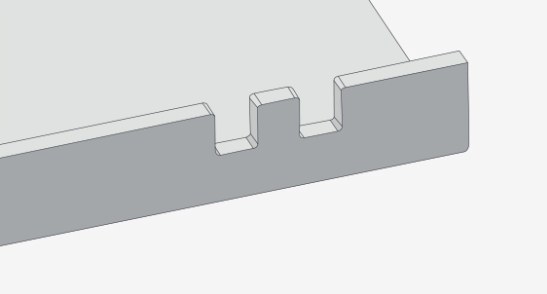

4. Iinotshi kunye neeTabs

Iinotshi kunye neetabhu zezona mpawu ziphambili zamalungu entsimbi aluncedo ekongezeni izikrufu okanye iziqhoboshi okanye ekufaka iindawo ezininzi kunye.Iinotshi ziziindenti ezincinci kumda wenxalenye, ngelixa iithebhu zibonakalisa iimpawu.Ithebhu kwindawo enye yentsimbi idla ngokudityaniswa ukuze ingene kwinotshi yenye inxalenye.

Njengezinye iimpawu zentsimbi, ukudala iinotshi ezifanelekileyo kunye neethebhu kufuneka zilandele imigaqo ethile: iinotshi kufuneka zibe ubuncinane bezinto eziphathekayo okanye i-1mm, nayiphi na into enkulu, kwaye ayinakuba ngaphezu kwama-5 ububanzi bayo.Iithebhu kufuneka ubuncinane 2 ukuphinda-phinda ubukhulu bezinto eziphathekayo okanye 3.2mm, nokuba yeyiphi enkulu, kwaye ayinakuba ngaphezulu kwe-5 ububanzi bayo.

5. Ii-Offsets kunye neeCountersinks

Ii-countersinks zingenziwa yi-CNC Machining okanye zenziwe ngezixhobo ezikhethekileyo.Ukunyamezela kwidayamitha enkulu ye-countersink kungqongqo kakhulu, kuba mhlawumbi kufuneka kusetyenziswe izikrufu okanye iziqhoboshi.I-Offsets isetyenziselwa ukwenza iiprofayili ezimilise u-Z kwiindawo zentsimbi.

6. Ukugqiba

Ngokuxhomekeke kwisicelo kunye nezinto ezisetyenzisiweyo, iinxalenye zeshidi zentsimbi zingagqitywa ngokuqhunyiswa kweentsimbi, i-anodizing, i-plating, i-powder coating kunye nezinye iinkqubo ezahlukeneyo, mhlawumbi ngeenjongo zokusebenza okanye ukuphucula nje ukubonakala kwenxalenye.