Umenzi wakho woMatshini ochanekileyo

PRECISION MACHINING

Ukuchaneka kwe-machining yinkqubo apho imilo okanye ukusebenza kwe-workpiece iguqulwa ngoomatshini bokucubungula. Ngokwemeko yobushushu bomsebenzi oza kucutshungulwa, yahlulahlulwe ibe yingqele ebandayo kunye nokulungiswa okushushu. Ngokuqhelekileyo, ukucubungula kwiqondo lokushisa, kwaye akubangeli utshintsho lweekhemikhali okanye isigaba somsebenzi, kuthiwa yi-cold processing. Ngokubanzi, ukusetyenzwa kuphezulu okanye ngaphantsi kobushushu obuqhelekileyo kuya kubangela utshintsho lwekhemikhali okanye lwesigaba somsebenzi, obizwa ngokuba yi-thermal processing. Ukucutshungulwa okubandayo kunokwahlulwa ngokucutshungulwa kunye nokucutshungulwa koxinzelelo ngokomahluko kwiindlela zokucubungula. Ukusetyenzwa kwe-Thermal ngokuqhelekileyo kubandakanya unyango lobushushu, ukubumba, ukuphosa kunye ne-welding.

Ukusetyenzwa kwamalungu e-auto yiyunithi equka ukusetyenzwa kwamalungu e-auto xa iyonke kunye neemveliso ezisebenzela ukusetyenzwa kwamalungu emoto. Njengesiseko soshishino lweemoto, iinxalenye zemoto zizinto eziyimfuneko ukuxhasa uphuhliso oluzinzileyo nolunempilo lweshishini lezimoto. Ngokukodwa, uphuhliso lwangoku oluzimeleyo kunye nokutsha kwishishini le-auto olwenziwa ngamandla kwaye ngokukhawuleza lufuna inkqubo yamalungu aqinileyo ukuyixhasa. Iimpawu ezizimeleyo zezithuthi kunye nokuveliswa kwezinto ezintsha zobuchwepheshe zifuna iinxalenye kunye namacandelo njengesiseko, kunye nokuveliswa okuzimeleyo kwamacandelo kunye namacandelo anamandla okuqhuba uphuhliso loshishino lwezithuthi. Banempembelelo kwaye basebenzisane omnye nomnye. Akukho phawu oluzimeleyo lwezithuthi ezipheleleyo, kunye nenkqubo yamalungu aqinileyo. I-R & D kunye nezakhono ezintsha zenkampani kunzima ukuqhuma, kwaye ngaphandle kwenkxaso yenkqubo yecandelo eliqinileyo, kuya kuba nzima kwiimpawu ezizimeleyo ukuba zibe zikhulu kwaye zomelele.

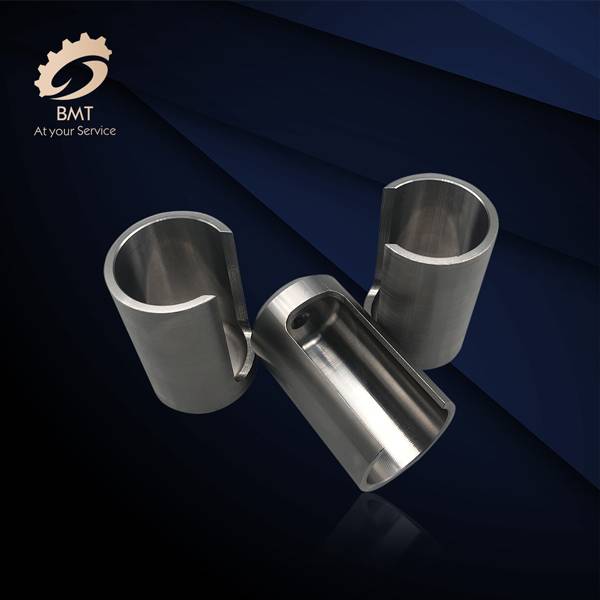

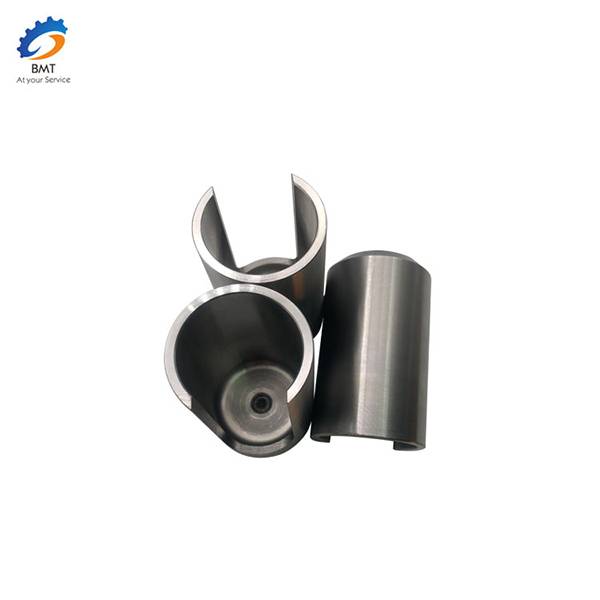

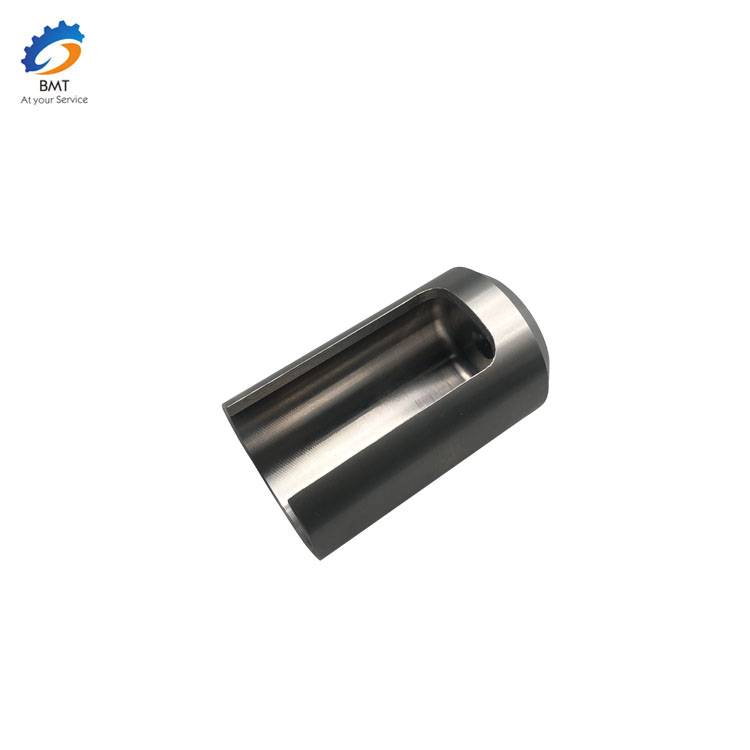

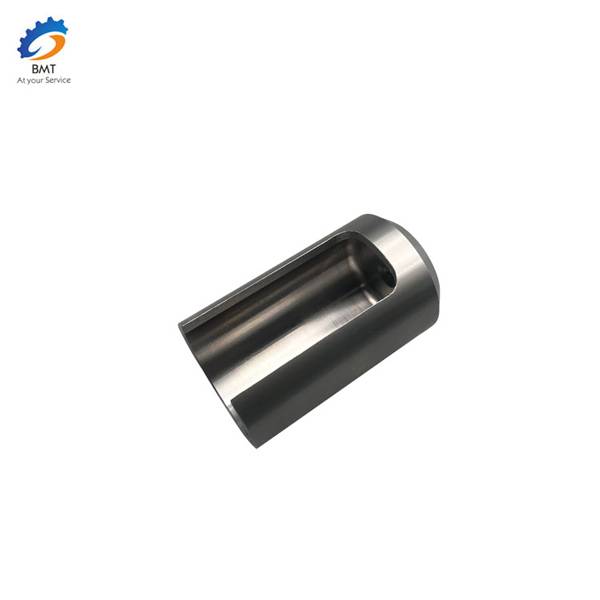

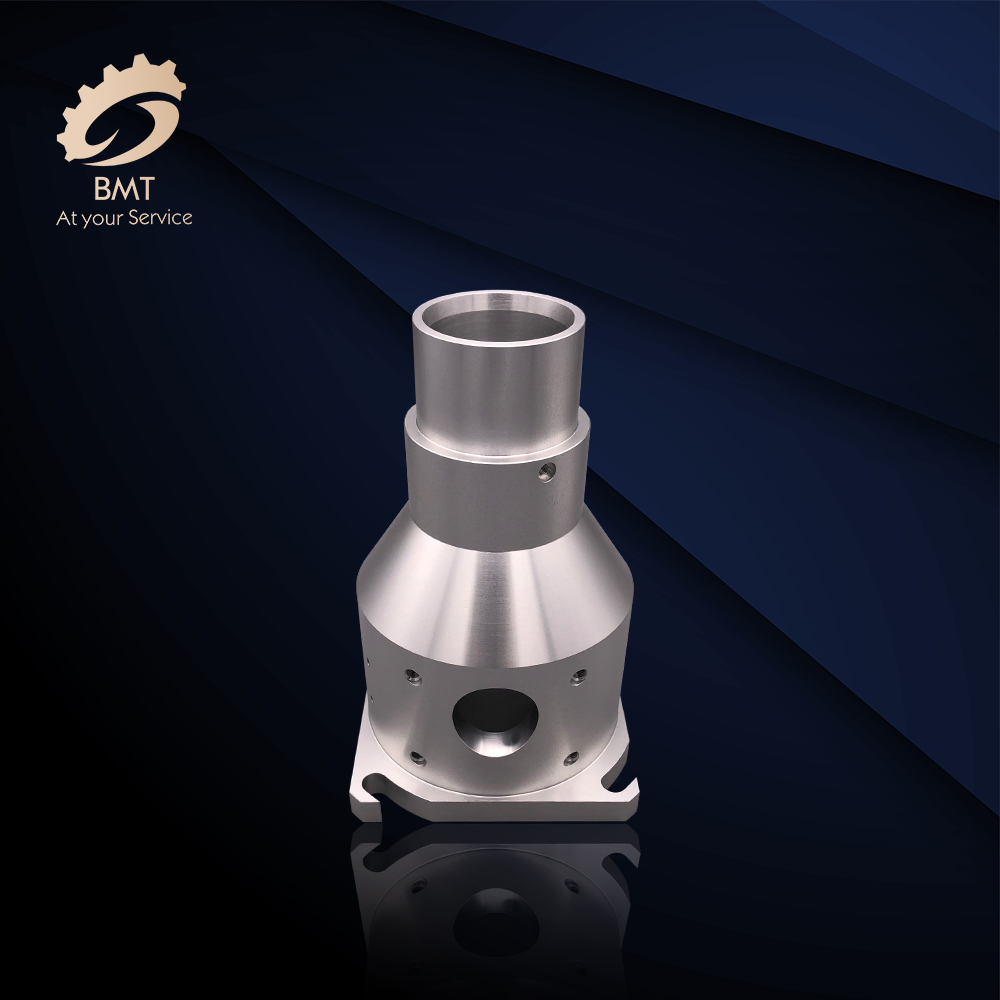

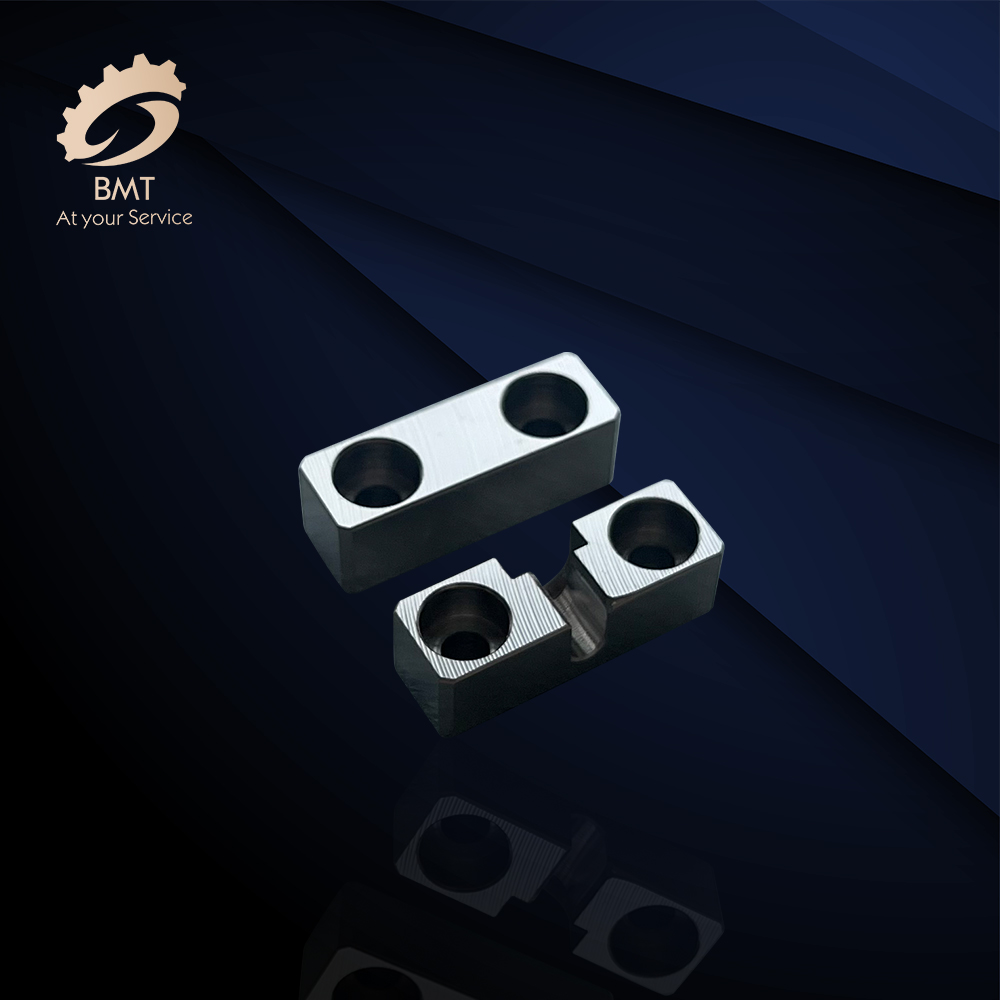

Amalungu abhekisa kumalungu azimeleyo angenakohlulwa ngoomatshini. Ziyizinto ezisisiseko zomatshini kunye neyunithi esisiseko kwinkqubo yokuvelisa umatshini. Inkqubo yokuvelisa ngokubanzi ayifuni inkqubo yokuhlanganisa. Njengemikhono, amahlathi, amantongomane, i-crankshafts, i-blades, i-gear, i-cams, imizimba yentonga edibanisayo, iintloko zeentonga ezidibanisayo, njl njl. Kwi-machining yethu echanekileyo, ukucubungula kungqongqo kakhulu, kwaye iinkqubo zokucubungula ziquka ukusika ngaphakathi nangaphandle. Kukho iimfuno ezithile zobukhulu kunye nokuchaneka, ezifana ne-1mm plus okanye minus micrometers, njl. Ukuba ubungakanani bukhulu kakhulu, buya kuchithwa. Ngeli xesha, kufana nokuphinda kuhlaziywe, kuthatha ixesha kunye nokusebenza nzima, kwaye ngamanye amaxesha kunye nayo yonke into eyenziwayo iyachithwa. Oku kubangele ukunyuka kweendleko, kwaye ngexesha elifanayo, iinxalenye azinakusebenziseka ngokuqinisekileyo.

Ezinye izixhobo eziqhelekileyo azikwazi ukugqiba ukusetyenzwa komngundo, njengeminye imingxuma eneengile ezincinci ze-R; ii-electrodes zicutshungulwa yi-pulse yombane. Ezi ngokuqhelekileyo zenziwe ngobhedu okanye igraphite. Uphuhliso olukhawulezayo lweteknoloji yokuvelisa i-mold ibe yinxalenye ebalulekileyo yeteknoloji yokuvelisa yanamhlanje. Itekhnoloji yokuvelisa i-mold yanamhlanje iphuhlisa kwicala lokukhawulezisa ulwazi lokuqhuba, ukuphucula ukuguquguquka kwemveliso, ukuveliswa kwe-agile kunye nokudibanisa inkqubo. Ibonakaliswe ngokukodwa kwi-CAD / CAM iteknoloji yokubumba, iteknoloji ye-laser ye-prototyping ye-mold, i-teknoloji echanekileyo yokwenza i-mold, kunye ne-ultra-precision processing technology ye-mold. Uyilo lokungunda lusebenzisa indlela yesiqalelo esinesiphelo kunye nendlela yesiqalelo somda ukwenza ukuhamba, ukupholisa kunye nenkqubo yokudlulisa ubushushu. Itekhnoloji yokulinganisa iDynamic, itekhnoloji ye-CIMS yokubumba, itekhnoloji yokuvelisa ephucukileyo efana nobuchwepheshe be-DNM yokubumba kunye nolawulo lwamanani buye baphuhliswa.