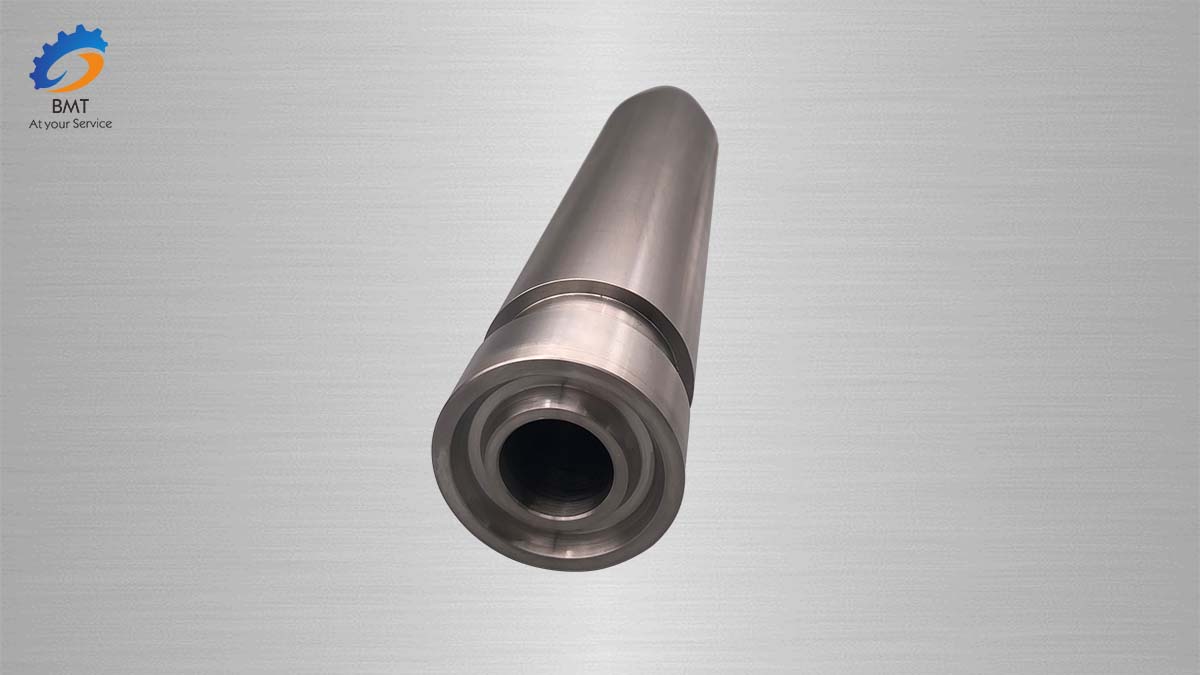

I-Titanium Alloy CNC Machining

Uxinzelelo lwe-machining ye-titanium alloys ifana kakhulu nomatshini wentsimbi kunezinyithi ezingenayo i-ferrous kunye ne-alloys. Iiparamitha ezininzi zenkqubo ye-titanium alloys ekwenziweni, isitampu somthamo kunye nesitampu samaphepha sisondele kwezo zisetyenzwa ngentsimbi. Kodwa kukho izinto ezibalulekileyo ekufuneka ziqwalaselwe xa ucinezela ukusebenza kweChin kunye neChin alloys.

Nangona ngokuqhelekileyo kukholelwa ukuba iilethi ezine-hexagonal eziqulethwe kwi-titanium kunye ne-titanium alloys zine-ductile encinci xa zikhubazekile, iindlela ezahlukeneyo zokusebenza zokushicilela ezisetyenziselwa ezinye iintsimbi zesakhiwo nazo zifanelekile kwi-alloys ye-titanium. Umlinganiselo wenqaku lesivuno ukuya kumda wamandla sesinye sezibonakaliso zeempawu zokuba isinyithi sinokumelana nokuguqulwa kweplastiki. Inkulu le ratio, imbi kakhulu iplastiki yentsimbi. Kwi-titanium ecocekileyo yoshishino kwimeko epholileyo, umlinganiselo ngu-0.72-0.87, xa kuthelekiswa ne-0.6-0.65 ye-carbon steel kunye ne-0.4-0.5 yensimbi engenasici.

Yenza i-volume stamping, i-forging yamahhala kunye neminye imisebenzi ehambelana nokusetyenzwa kwe-cross-section enkulu kunye nezithuba ezinkulu zobukhulu obungabhalwanga kwimeko eshushu (ngaphezu kweqondo lokushisa = yS). Uluhlu lweqondo lobushushu lokubumba kunye nesitampu sokufudumeza luphakathi kwe850-1150°C. Iingxubevange BT; I-M0, BT1-0, OT4~0 kunye ne-OT4-1 ine-deformation yeplastiki eyanelisayo kwimeko epholileyo. Ke ngoko, iinxalenye ezenziwe zezi alloys ubukhulu becala zenziwe nge-intermediate anneal blanks ngaphandle kokufudumeza kunye nesitampu. Xa ingxubevange ye-titanium ibanda ngokweplastiki, kungakhathaliseki ukuba i-chemical composition kunye neempawu zoomatshini, amandla aya kuphuculwa kakhulu, kwaye iplastiki iya kuncitshiswa ngokuhambelanayo. Ngenxa yesi sizathu, unyango lwe-annealing phakathi kweenkqubo kufuneka lwenziwe.

Ukunxitywa kwe-groove yokufaka kwi-machining ye-titanium alloys kukunxitywa kwendawo yangasemva nangaphambili kwicala lobunzulu bokusikwa, okuhlala kubangelwa ngumaleko olukhuni oshiywe yinkqubo yangaphambili. Ukusabela kweekhemikhali kunye nokusasazwa kwesixhobo kunye nezixhobo zokusebenza kwiqondo lokushisa elingaphezulu kwe-800 °C sesinye sezizathu zokwenza ukunxiba kwe-groove. Ngenxa yokuba ngexesha lenkqubo yomatshini, iimolekyuli ze-titanium ze-workpiece ziqokelela phambi kwe-blade kwaye "zifakwe kwi-welded" kwi-blade edge phantsi koxinzelelo oluphezulu kunye nobushushu obuphezulu, zenza umda owenziweyo. Xa i-edge eyakhiweyo ikhupha kwi-cut cut, i-carbide coating ye-insert ithathwa.

Ngenxa yokumelana nobushushu kwe-titanium, ukupholisa kubalulekile kwinkqubo yomatshini. Injongo yokupholisa kukugcina i-edge yokusika kunye nesixhobo sobuso ekugqithiseni. Sebenzisa isiphelo sokupholisa ukukhutshwa kwetshiphu ngeyona ndlela xa usenza ukungqusha emagxeni kunye neepokotho zokusila zobuso, iipokotho okanye igrooves epheleleyo. Xa usika isinyithi se-titanium, ii-chips zilula ukunamathela kwi-cut cut, ebangela ukuba umjikelo olandelayo we-milling cutter unqumle ii-chips kwakhona, ngokuphindaphindiweyo ubangela ukuba umgca we-edge ube yi-chip.

Umngxuma ngamnye wokufaka unomngxuma wokupholisa/isitofu ukujongana nalo mba kunye nokuphucula ukusebenza komphetho othe rhoqo. Esinye isisombululo esicocekileyo yimingxuma yokupholisa enemisonto. Abasiki bexesha elide lokusila banezifakelo ezininzi. Ukufaka isisipholisi kumngxuma ngamnye kufuna umthamo wempompo ephezulu kunye noxinzelelo. Kwelinye icala, inokuqhobosha imingxuma engadingekiyo njengoko ifuneka, ngaloo ndlela ikhulisa ukugeleza kwimingxuma efunekayo.

Thumela umyalezo wakho kuthi:

-

Aluminiyam CNC Machining Parts

-

I-Aluminiyam yePhepha leMetal Fabrication

-

Axis High Precision CNC Machining Parts

-

Izahlulo zoomatshini be-CNC base-Itali

-

CNC Machining Aluminiyam iinxalenye

-

Auto Parts Machining

-

I-Titanium Alloy Forgings

-

I-Titanium kunye ne-Titanium Alloy Fittings

-

I-Titanium kunye ne-Titanium Alloy Forgings

-

Iingcingo zeTitanium kunye neTitanium Alloy

-

Iibha zeTitanium

-

Imibhobho yeTitanium engenamthungo/iiThubhu

-

I-Titanium Welded imibhobho / iiThubhu