IiBar zeTitanium kunye neTitanium Alloy

I-alloys ye-Titanium inokwahlulwa ibe ngamacandelo amathathu ngokubunjwa kwezigaba: i-alloy α, (α + β) i-alloy kunye ne-β alloy, echazwe ngokulandelanayo yi-TA, TC kunye ne-TB e-China.

① I-alloy ye-alloy iqulethe umlinganiselo othile wezinto ezinesigaba esizinzile sika-α kwaye ikakhulu yenziwe ngesigaba sika-α kwisimo sokulingana. I-alloys ye-α inomxhuzulane okhethekileyo omncinci, amandla afanelekileyo e-thermal, ukuwelda okulungileyo kunye nokumelana nokugqwesa okugqwesileyo. Ukungalungi amandla aphantsi kwiqondo lokushisa, kwaye ngokuqhelekileyo zisetyenziswa njengezinto ezichasene nokushisa kunye ne-corrosion resistant. i-alloys eneengxube ezimbalwa (Ti-2.5Cu).

I-② (α + β) i-alloy iqulethe inani elithile lezinto ezinesigaba esizinzile se-α kunye nesigaba se-β, kunye ne-microstructure ye-alloy kwisimo sokulinganisa i-α isigaba kunye nesigaba se-β. I-alloy (α + β) inamandla aphakathi kwaye ingaba ukomelezwa ngonyango lobushushu, kodwa i-weldability impofu. (α + β) i-alloys isetyenziswa ngokubanzi, kwaye imveliso ye-Ti-6Al-4V i-alloys i-akhawunti ngaphezu kwesiqingatha sezinto zonke ze-titanium.

① i-alloy ye-β iqulethe inani elikhulu lezinto ezizinzile kwisigaba se-β, iqondo lobushushu eliphezulu β isigaba sinokugcinwa kwiqondo lokushisa. I-alloy ye-β ephathwa ngokushisa ine-ductility egqwesileyo kwimeko yokucima kwaye inokufikelela kumandla obunzima be-130 ~ 140kgf / mm2 ngokuguga unyango.β i-alloys isetyenziswa ngokuqhelekileyo njengamandla aphezulu kunye nezixhobo eziphezulu zobunzima. ukusebenza, ubunzima bomatshini.

Imigangatho yokucaphula

1: GB 228 Iindlela zokuvavanya i-Metallic tensile

2: GB/T 3620.1 Ibanga le-titanium kunye ne-titanium alloy kunye nokwakheka kweekhemikhali

3: I-GB/T3620.2 i-titanium kunye ne-titanium alloy processing imveliso yokwakheka kweekhemikhali kunye nokwakheka kokutenxa okuvumelekileyo

I-GB 4698 Iindlela zokuhlalutya iikhemikhali zesiponji se-titanium, i-titanium kunye ne-titanium alloys

GB: GB/T2965-2007, GB/T13810, Q/BS5331-91

Umgangatho waseMelika: ASTM B348, ASTM F136, ASTM F67, AMS4928

Iimfuno zobugcisa

I-1: Ukwakhiwa kweekhemikhali ze-titanium kunye ne-titanium alloy bars kuya kuhambelana nemimiselo ye-GB / T 3620.1. Xa uvavanyo oluphindaphindiweyo lufunekayo, ukuphambuka okuvumelekileyo kokwakheka kweekhemikhali kuya kuhambelana nemimiselo ye-GB / T 3620.2.

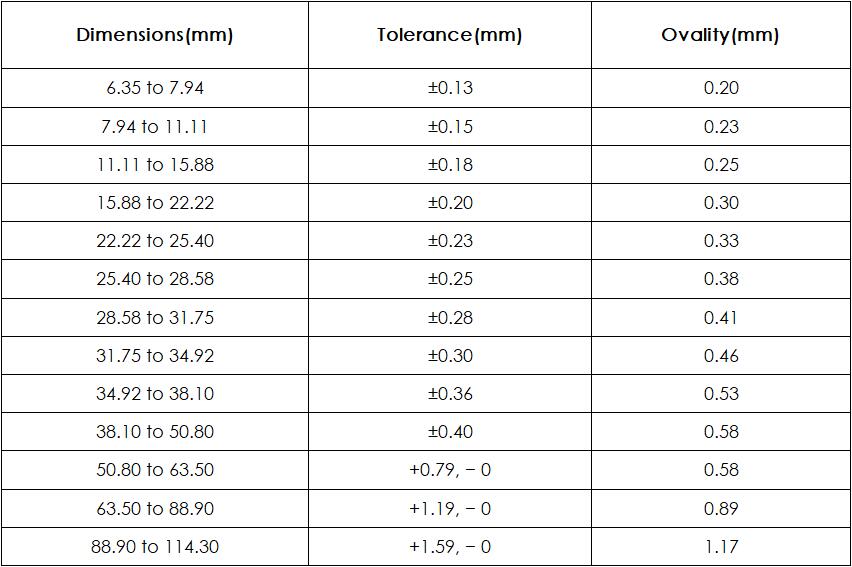

2: Idayamitha okanye ubude becala lebha yokusebenza eshushu kunye nokutenxa kwayo okuvumelekileyo kuya kuhambelana namalungiselelo akwiThebhile 1.

3: Emva kokusebenza okushushu, ukutenxa okuvumelekileyo kwedamitha yebar etsalwa ngokubanda kuya kuhambelana namalungiselelo akwiThebhile 2 emva kokuqengqeleka (ukugaya) ibha epholisiweyo kunye nokuqengqeleka okubandayo.

I-4: emva kokulungiswa okutshisayo ngemoto (ukugaya) ibha yokukhanya yokujikeleza akufanele ibe ngaphezu kwesiqingatha sokunyamezela kwayo.

I-5: ubude bobude obunganqunywanga bebha yesimo esicwangcisiweyo yi-300-6000mm, ubude bobude obungapheliyo be-bar state annealed yi-300-2000mm, kunye nobude obusisigxina okanye ubude obuphindwe kabini bufanele bube phakathi kobude obungapheliyo. .Ukutenxa okuvumelekileyo kobude obumiselweyo yi-+20mm; Ubude bobude obuphindwe kabini buya kufakwa kwisixa esisikiweyo sebha, kwaye isixa ngasinye esisikiweyo siya kuba yi-5mm. Ubude bobude obumiselweyo okanye ubude bobude obuphindwe kabini buya kuchazwa kwikhontrakthi.

Iinkcukacha: ukuqengqeleka ¢8.0-- 40mm× L; Ukuqulunqa ¢40-150 - mm x L

Isakhiwo se-metallographic: ubungakanani benkozo ye-titanium ecocekileyo ayikho ngaphantsi kwebanga lesi-5, i-TC4 ye-titanium alloy ngokuhambelana ne-A1-A9.

Umphezulu: umphezulu omnyama, umgangatho okhazimlisiweyo, umgangatho okhazimlisiweyo (H11, H9, H8)

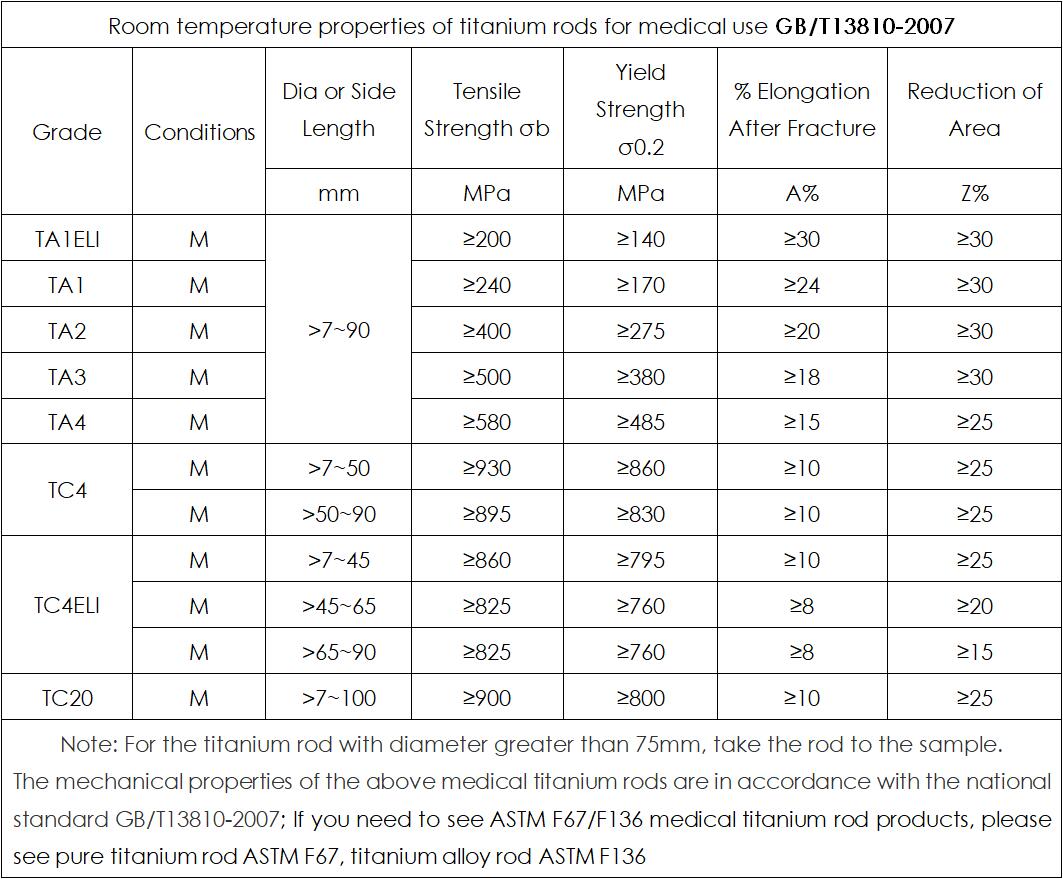

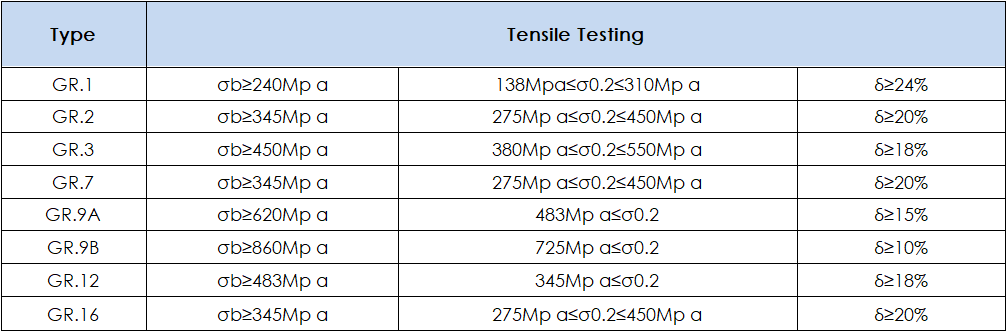

Ukusebenza kwentonga ye-titanium yonyango (umgangatho wokubhekisela :GB/T13810-2007,ASTM F67/F136).

Sivelisa kwaye sithumela ngaphandle kwe-ASTM ibha yetitanium esemgangathweni kunye neMigangatho yaseTshayina (GB) esemgangathweni yetitanium bar, kunye nebha yetitanium yomgangatho ekuvunyelwene ngawo.

Ukuba siphakathi kwabavelisi abambalwa abanokuqonda ulawulo lomgangatho kuyo yonke inkqubo yemveliso, siphumeza ulawulo olungqongqo lomgangatho ukusuka ekunyibilikeni kwempahla ekrwada yesiponji setitanium ukuya kwiimveliso ezigqityiweyo.

Ukuba nomgangatho weprimiyamu kunye nokulandela umkhondo kunye nenkonzo egqibeleleyo, sithengisa iimveliso ezibandakanya ibha ye-titanium yonyango, ibha yokupholisha ye-titanium kunye ne-titanium alloy bar kwihlabathi liphela. Siye saba ngomnye wababoneleli abakhulu kunye nabathengisi be-titanium bar eTshayina.

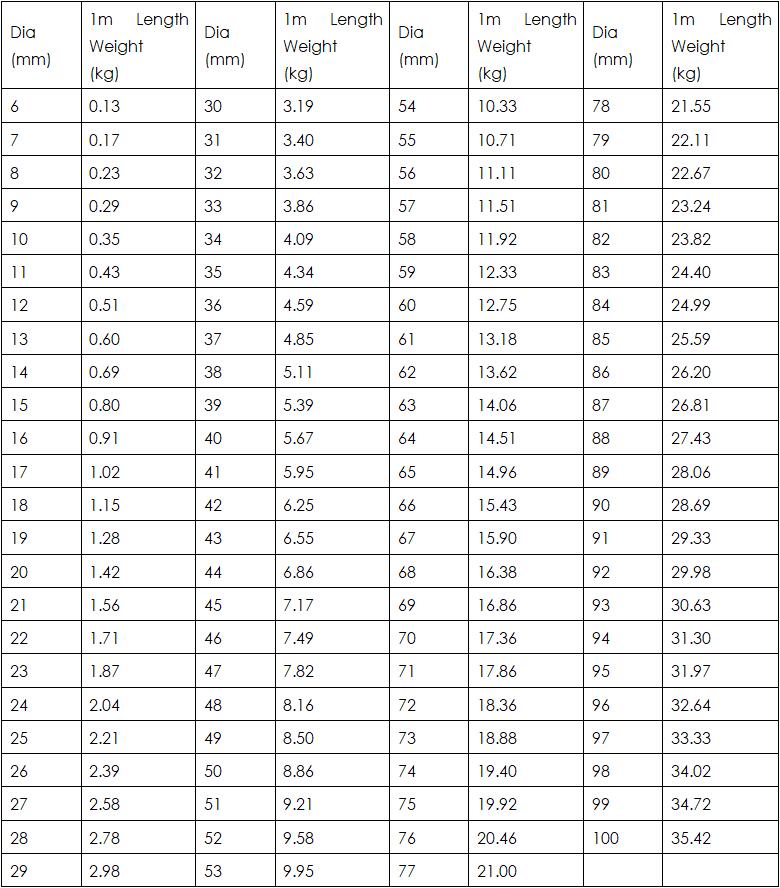

Uluhlu lobungakanani: Ububanzi 6-200mm x Max 6000mm

Iipropati zeqondo lokushisa kwegumbi leentonga ze-titanium zokusetyenziswa kwezonyango GB/T13810-2007:

Ubungakanani Esibenzileyo:

Imilinganiselo, uNyamezelo kunye noLuhlu lwe-Ovality:

Ukwakheka kweMichiza yeMathiriyeli ekhoyo

Ukwakheka kweMichiza yeMathiriyeli ekhoyo

Uvavanyo lokuhlola:

- Uvavanyo lwe-NDT

- Uvavanyo lwe-ultrasonic

- Uvavanyo lwe-LDP

- Uvavanyo lweFerroxyl

Imveliso (Ubuninzi kunye neMini encinci yoMyalelo):Unlimited, ngokomyalelo.

Ixesha lokukhokhela:Ixesha lokukhokela ngokubanzi ziintsuku ezingama-30. Nangona kunjalo, kuxhomekeke kwisixa somyalelo ngokufanelekileyo.

Ezothutho:Indlela jikelele yothutho luLwandle, ngoMoya, nge-Express, ngoLoliwe, oya kunyulwa ngabathengi.

Ukupakisha:

- Umbhobho uphela ukuba ukhuselwe ngeplastiki okanye i-caps cardboard caps.

- Zonke izifakelo kufuneka zipakishwe ukukhusela iziphelo kunye nokujongana.

- Zonke ezinye iimpahla ziya kupakishwa ngeephedi zogwebu kunye nokupakishwa kweplastiki ehambelanayo kunye neekesi zeplywood.

- Nawuphi na umthi osetyenziselwa ukupakisha kufuneka ulungele ukuthintela ukungcoliseka ngokudibana nezixhobo zokuphatha.