Ukuzenzekela koomatshini

Kubandakanya i-nickel-based alloys ethambileyo yamagnetic, i-nickel-based precision resistance alloys kunye ne-nickel-based electrothermal alloys. Ezona zinto zixhaphakileyo zisetyenziswa ngokuthambileyo iialloyi ezinozibuthe ziipermalloys eziqulathe malunga ne80% yenikeli. Banobuninzi obuphezulu kunye nokunyanzeliswa kokuqala kunye nokunyanzeliswa okuphantsi. Zizinto ezibalulekileyo ezingundoqo kwishishini le-elektroniki. Izinto eziphambili zokuxutywa kwe-nickel-based precision resistance alloys yi-chromium, i-aluminiyam kunye nobhedu.

Le ngxubevange inokumelana okuphezulu, i-coefficient ephantsi yobushushu be-resistivity kunye ne-corrosion resistance resistance, kwaye isetyenziselwa ukwenza i-resistors. I-Nickel-based electrothermal alloy yi-nickel alloy ene-20% yechromium, ene-anti-oxidation kunye ne-anti-corrosion properties, kwaye ingasetyenziselwa ixesha elide kubushushu obuyi-1000-1100 °C.

I-Memory Alloy

I-nickel alloy ene-50 (at)% titanium. Iqondo lokushisa lokubuyisela liyi-70 ° C, kwaye umphumo wememori wemilo ulungile. Utshintsho oluncinci kwi-nickel-titanium composition ratio inokutshintsha ubushushu bokubuyisela phakathi koluhlu lwe-30 ukuya kwi-100 °C. Isetyenziswa kakhulu kukwenziwa kwezandiso zamalungu olwakhiwo asetyenziswa kwisiphekepheke, iziqhoboshi eziziqinisayo ezisetyenziswa kwishishini le-aerospace, iimotor zentliziyo ezenziweyo ezisetyenziswa kwi-biomedicine, njl.

Indawo yosetyenziso

I-alloys esekwe kwi-nickel isetyenziswa kwiindawo ezininzi, ezinje ngale:

1. Ulwandle: izakhiwo zaselwandle kwimekobume yolwandle, ukuchithwa kwamanzi olwandle, ukuveliswa kwamanzi olwandle, ukutshintshisana kobushushu bamanzi olwandle, njl.

2. Intsimi yokukhusela indalo: isixhobo se-flue gas desulfurization yokuvelisa umbane oshushu, ukucocwa kwamanzi amdaka, njl.

3. Intsimi yamandla: ukuveliswa kwamandla eathom, ukusetyenziswa ngokupheleleyo kwamalahle, ukuveliswa kwamandla olwandle, njl.

4. Intsimi yePetrochemical: ukucocwa kweoli, izixhobo zeekhemikhali kunye neekhemikhali, njl.

5. Intsimi yokutya: ukwenza ityuwa, ukwenza i-soy sauce, njl. Kwiindawo ezininzi ezingentla apha, intsimbi eqhelekileyo ye-stainless 304 ayinakukwazi. Kule mihlaba ikhethekileyo, intsimbi ekhethekileyo engenastainless iyimfuneko kwaye ayinakubuyiselwa. Kwiminyaka yakutshanje, kunye nophuhliso olukhawulezayo loqoqosho kunye nokuphuculwa okuqhubekayo kwinqanaba lecandelo lezoshishino, iiprojekthi ezininzi zifuna i-stainless steel stainless. Ngokukhula kwemfuno ye-nickel-based alloys kumashishini ahlukeneyo. Ngo-2011, isikali semarike ye-nickel esekwe kwi-nickel yelizwe lam yafikelela kwi-23.07 yeebhiliyoni zeeyuan, izinga lokukhula lonyaka nge-19.47%. Ke ngoko, inqanaba lophuhliso loshishino likwindlela ethe gqolo ukuya phezulu.

Uphuhliso oluyimpumelelo lwezixhobo ezininzi ezipheleleyo ezahlukeneyo zenze ulwakhiwo lweeprojekthi ezingundoqo ezahlukeneyo zenzeke; ukuchaneka koomatshini kunye nezixhobo kuqhube ishishini le-microelectronics kunye neshishini lekhompyuter. Ukuveliswa okudibeneyo kweesekethe ezidibeneyo kuye kwafezekiswa kwaye umthamo wememori uphindwe kabini; uphuhliso kunye nokuveliswa kwe-aerospace kunye nezixhobo ezahlukeneyo kunye nezixhobo, ukuphuhliswa kwesayensi kunye neteknoloji kunye nemfundo konke kuxhomekeke ekuqhubeleni phambili koyilo lomatshini kunye nobugcisa bokuvelisa.

Oku kubalulekileyo kukhulisa ulwazi olusisiseko kunye nobuchule bokusebenzisa boyilo lomatshini kunye nokuveliswa, kunye nophuhliso lweemveliso ezintsha ze-electromechanical.

Thumela umyalezo wakho kuthi:

-

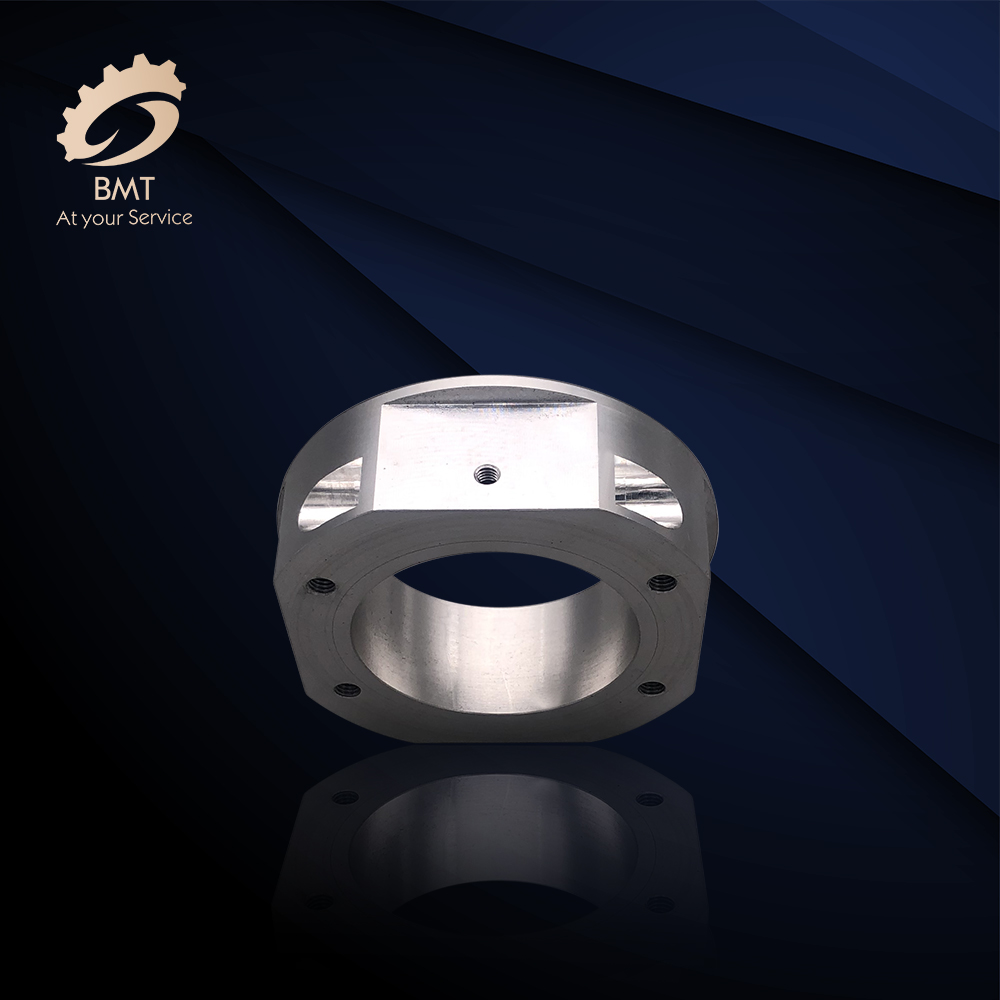

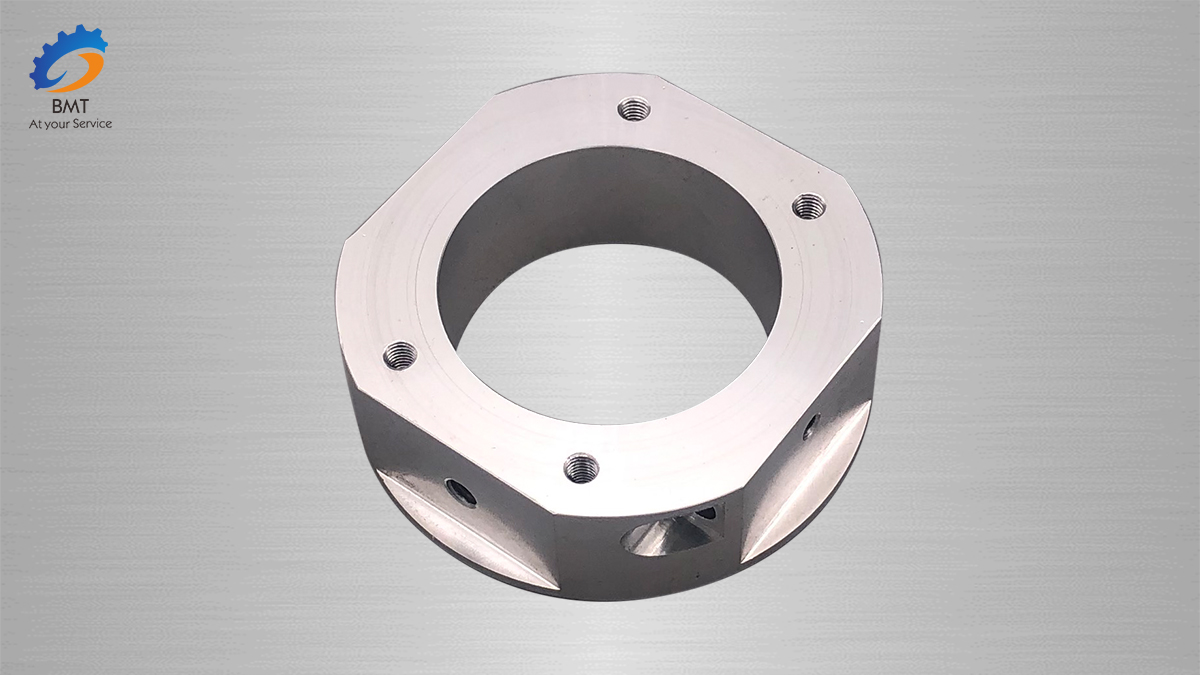

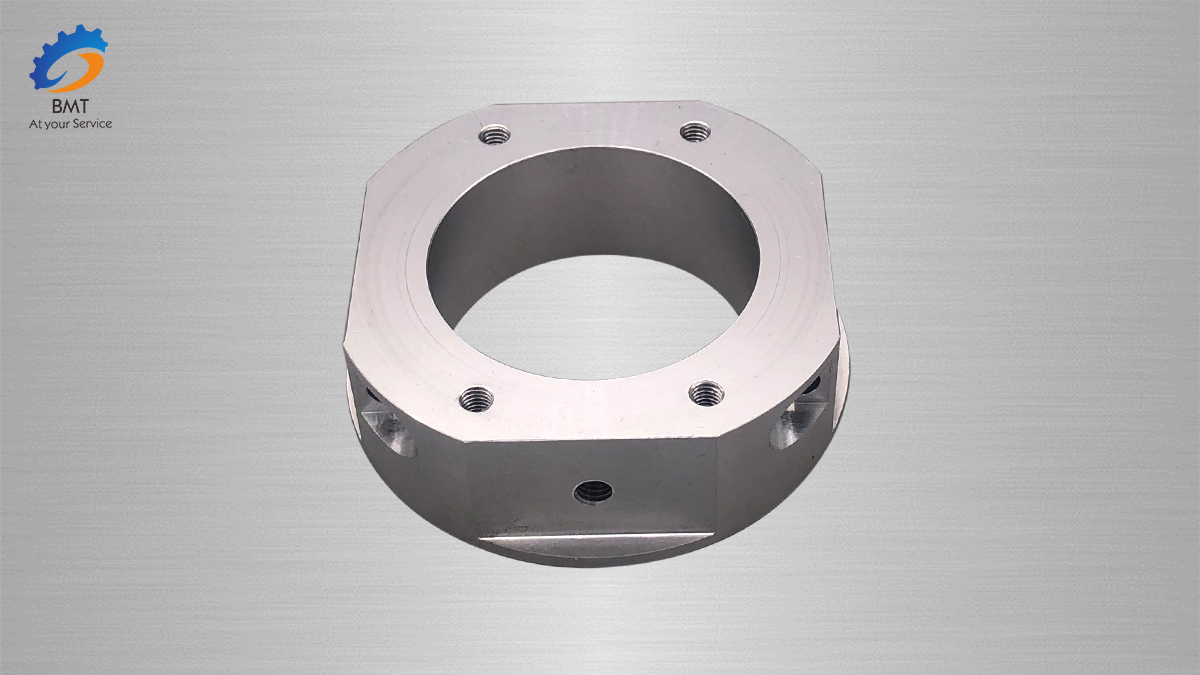

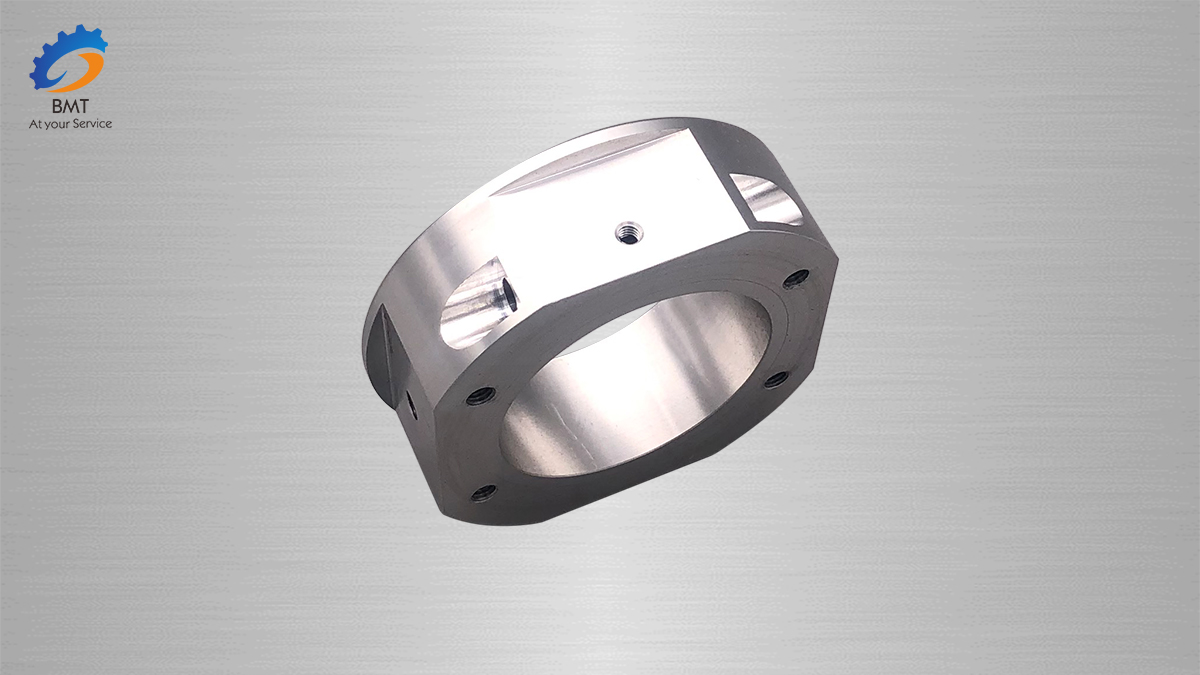

Aluminiyam CNC Machining Parts

-

I-Aluminiyam yePhepha leMetal Fabrication

-

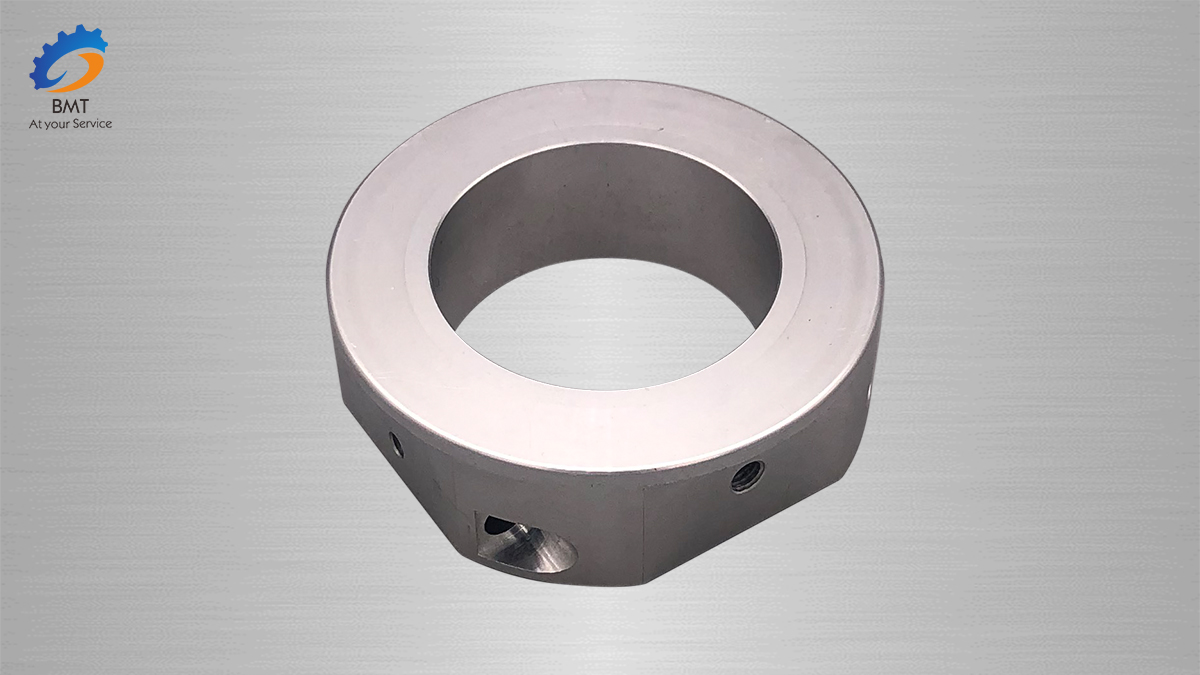

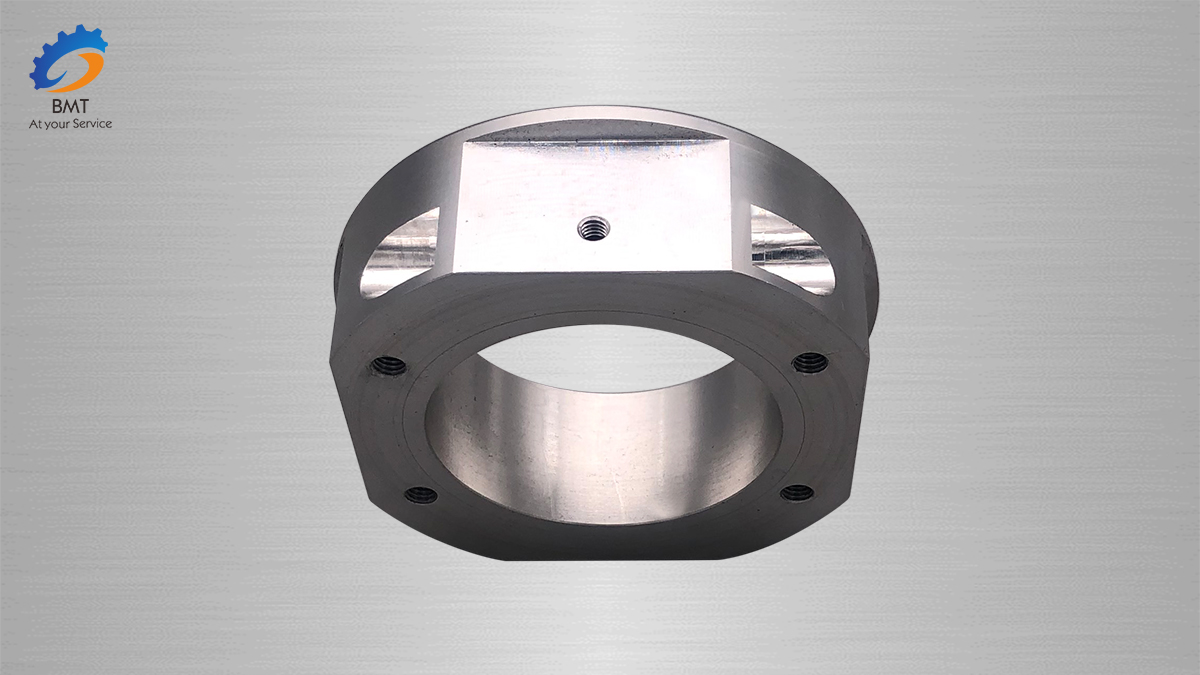

Axis High Precision CNC Machining Parts

-

Izahlulo zoomatshini be-CNC base-Itali

-

CNC Machining Aluminiyam iinxalenye

-

Auto Parts Machining

-

I-Titanium Alloy Forgings

-

I-Titanium kunye ne-Titanium Alloy Fittings

-

I-Titanium kunye ne-Titanium Alloy Forgings

-

Iingcingo zeTitanium kunye neTitanium Alloy

-

Iibha zeTitanium

-

Imibhobho yeTitanium engenamthungo/iiThubhu

-

I-Titanium Welded imibhobho / iiThubhu