IZakhono zokuKhetha izixhobo zeCNC Machining

Khetha izixhobo ze-CNC Milling

Kumatshini we-CNC, ii-mill-bottomed end mill ziqhele ukusetyenziselwa ukugaya iicontours zangaphakathi nangaphandle zamalungu endiza kunye nenqwelomoya yokusila.Idatha ye-empirical yeeparamitha ezifanelekileyo zesixhobo zezi zilandelayo: Okokuqala, i-radius ye-gritter yokusila kufuneka ibe yincinci kune-radius encinci ye-curvature i-Rmin ye-contour surface yangaphakathi yecandelo, ngokubanzi i-RD= (0.8-0.9) Rmin .Okwesibini kukuphakama kokucubungula kwenxalenye H < (1/4-1/6) RD ukuqinisekisa ukuba ummese unobunzima obaneleyo.Okwesithathu, xa ukugaya umphantsi wegroove engaphakathi kunye nesiphelo sesiphelo se-flat-bottomed, kuba iipaseji ezimbini ze-groove ezantsi kufuneka zigqithe, kwaye i-radius yomgca ongezantsi wesixhobo yiRe=Rr, oko kukuthi, Idayamitha ngu-d=2Re=2(Rr), xa udweliso lwenkqubo Thatha iradiyasi yesixhobo njengeRe=0.95 (Rr).

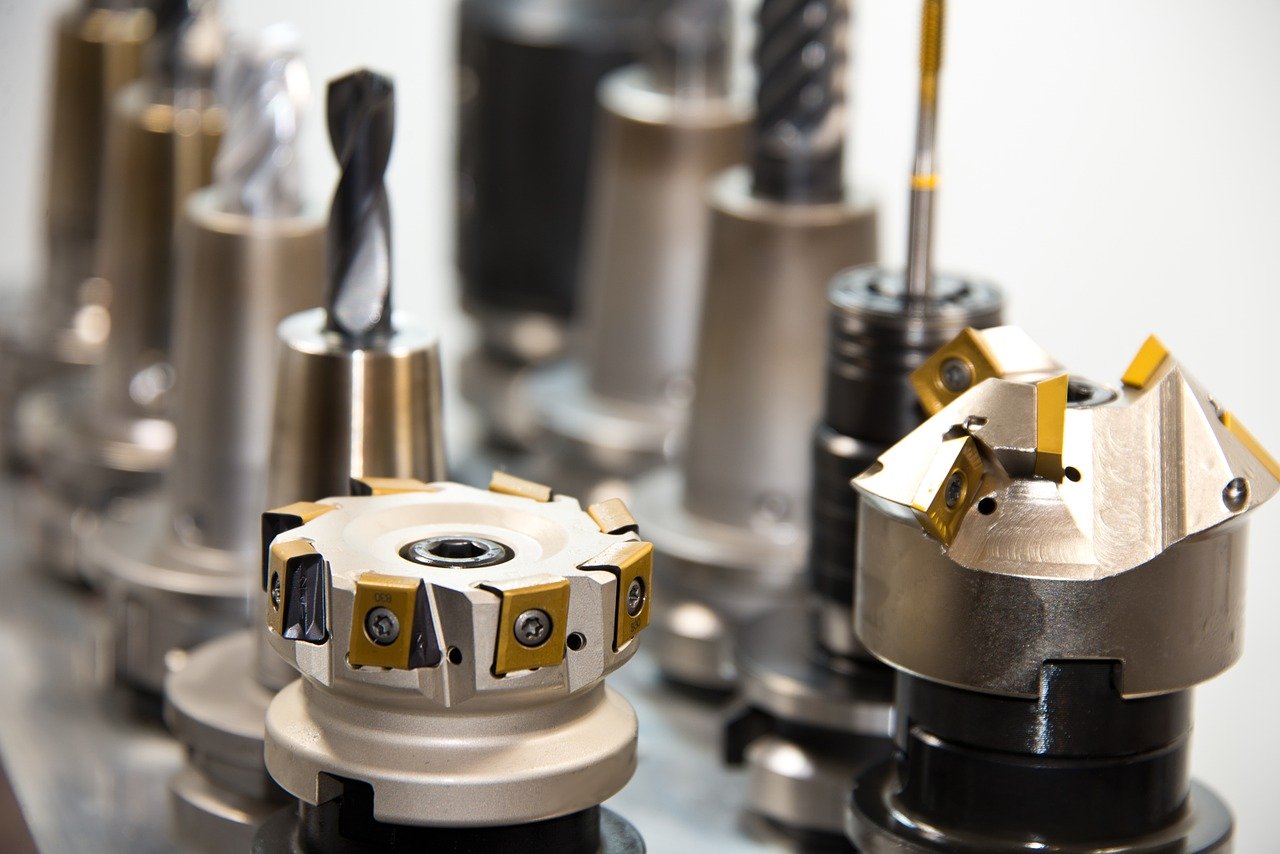

Ukusetyenzwa kwezinye iiprofayili ezinomacala amathathu kunye neecontour ezineengile eziguquguqukayo ze-bevel, izisiki zokusila ezingqukuva, izisiki zokusila, izisiki zokusila, izisiki zokusila ezinetapered kunye nezisiki zokusila iidisk ziqhele ukusetyenziswa.Okwangoku, uninzi lwezixhobo zoomatshini be-CNC zisebenzisa izixhobo ezisetyenzisiweyo kunye nemigangatho.Kukho imigangatho yesizwe kunye neemodeli ezilandelelanayo zabanini bezixhobo kunye neentloko zezixhobo ezifana ne-indexable machine-clamped yangaphandle izixhobo zokujika kunye nezixhobo zokuguqula ubuso.Kumaziko omatshini kunye nabaguquli bezixhobo ezizenzekelayo Izixhobo zomatshini ezifakiweyo kunye nabaphathi bezixhobo ziye zahlelwa kwaye zisemgangathweni.Ngokomzekelo, ikhowudi esemgangathweni yenkqubo yesixhobo se-tapered shank yi-TSG-JT, kunye nekhowudi eqhelekileyo yenkqubo yesixhobo se-shank echanekileyo yi-DSG-JZ.Ukongeza, kwisixhobo esikhethiweyo Ngaphambi kokusetyenziswa, kuyimfuneko ukulinganisa ngokungqongqo ubungakanani besixhobo ukuze ufumane idatha echanekileyo, kwaye umqhubi uya kufaka ezi datha kwinkqubo yedatha, kwaye agqibezele inkqubo yokucubungula ngokufowunelwa kwenkqubo, ngaloo ndlela kusetyenzwa ii-workpieces ezifanelekileyo. .

Indawo yesixhobo sokuSonga kunye neNdawo yoTshintsho lweSixhobo

Siqala kweyiphi indawo isixhobo ukuya kwindawo echaziweyo?Ngoko ekuqaleni kokuphunyezwa kweprogram, indawo apho isixhobo siqala ukuhamba kwinkqubo yokulungelelanisa i-workpiece kufuneka imiselwe.Esi sikhundla sisiqalo sesixhobo esinxulumene nomsebenzi xa inkqubo isenziwa.Ngoko ke ibizwa ngokuba yindawo yokuqalisa inkqubo okanye indawo yokuqalisa.Le ndawo yokuqala igqitywe ngokubanzi ngokusetwa kwesixhobo, ke le ndawo ikwabizwa ngokuba yindawo yokumisela isixhobo.Xa uqulunqa inkqubo, indawo yendawo yokumisela isixhobo kufuneka ikhethwe ngokuchanekileyo.Umgaqo wesixhobo sokumisela indawo yokumisela kukuququzelela ukusetyenzwa kwamanani kunye nokwenza lula inkqubo.

Kulula ukulungelelanisa kunye nokukhangela ngexesha lokucubungula;imposiso yokucubungula ebangelwe incinci.Isixhobo sokumisela isixhobo sinokusetwa kwicandelo lomatshini, kwindawo yokulungisa okanye kwisixhobo somatshini.Ukuze kuphuculwe ukuchaneka komatshini wenxalenye, indawo yokumisela isixhobo kufuneka imiselwe kangangoko kunokwenzeka kwisalathiso soyilo lwenxalenye okanye isiseko senkqubo.Ekusebenzeni kwangempela kwesixhobo somatshini, indawo yokumisa isixhobo ingafakwa kwindawo yokumisela isixhobo ngokusebenza kwesixhobo sokuseta ngesandla, oko kukuthi, ukuhambelana kwe "ndawo yesixhobo sokumisa" kunye "nendawo yokumisela isixhobo".Into ebizwa ngokuba "indawo yendawo yesixhobo" ibhekisela kwindawo yokubeka i-datum yesixhobo, kwaye indawo yendawo yesixhobo sokuguqula isixhobo sisixhobo okanye iziko le-arc yesixhobo.

Isiphelo sokusila esisezantsi esisicaba yi-intersection ye-axis yesixhobo kunye nezantsi kwesixhobo;i-ball-end mill yimbindi yebhola, kwaye i-drill yingongoma.Ukusebenzisa ukusetyenziswa kwesixhobo sokuseta ngesandla, ukuchaneka kokuseta isixhobo kuphantsi, kwaye ukusebenza kakuhle kuphantsi.Ezinye iifektri zisebenzisa i-optical tool setting mirror, izixhobo zokuseta izixhobo, izixhobo zokucwangcisa izixhobo ezizenzekelayo, njl.njl. ukunciphisa ixesha lokuseta isixhobo kunye nokuphucula ukuchaneka kwesixhobo.Xa isixhobo kufuneka sitshintshwe ngexesha lokucubungula, indawo yokutshintsha isixhobo kufuneka icaciswe.Into ebizwa ngokuba "indawo yokutshintsha isixhobo" ibhekisa kwindawo yesithuba sesixhobo xa sijikeleza ukutshintsha isixhobo.Indawo yokutshintsha isixhobo kufuneka ibekwe ngaphandle kwendawo yokusebenza okanye i-fixture, kwaye i-workpiece kunye nezinye iindawo akufanele zichukunyiswe ngexesha lokutshintsha isixhobo.

Incam yolu hlobo lwesixhobo sokuguqula iqulethwe ngamacandelo aphambili kunye nesibini, njengezixhobo ze-900 zokuguqula zangaphakathi nangaphandle, izixhobo zokuguqula ubuso ngasekhohlo nasekunene, izixhobo zokuguqula i-grooving (ukusika), kunye nemida eyahlukeneyo yokusika yangaphandle nangaphakathi. ama-chamfers amancinci amancinci.Isixhobo sokuguqula umngxuma.Indlela yokukhethwa kweeparameters zejometri yesixhobo sokujika esichongiweyo (ingakumbi i-angle yejometri) ngokusisiseko iyafana neyokujika okuqhelekileyo, kodwa iimpawu ze-CNC machining (ezifana nomzila womatshini, ukuphazamiseka komatshini, njl. njl.) kufuneka ziqwalaselwe ngokubanzi. , kunye nencam yesixhobo ngokwayo kufuneka ithathwe njengamandla.

Gqiba Isixa Sokusika

Kwiprogram ye-NC, umdwelisi weprogram kufuneka anqume inani lokusika inkqubo nganye kwaye ayibhale kwiprogram ngendlela yemiyalelo.Iiparamitha zokusika ziquka isantya se-spindle, isixa sokusika umva kunye nesantya sokutya.Kwiindlela ezahlukeneyo zokucutshungulwa, iiparamitha ezahlukeneyo zokusika kufuneka zikhethwe.Umgaqo wokukhethwa kwexabiso lokusika kukuqinisekisa ukuchaneka komatshini kunye noburhabaxa bomhlaba wamacandelo, ukunika umdlalo opheleleyo ekusebenzeni kokusika kwesixhobo, ukuqinisekisa ukuqina kwesixhobo esinengqiqo, kunye nokunika umdlalo opheleleyo ekusebenzeni kwesixhobo somatshini ukwandisa imveliso. kunye nokunciphisa iindleko.